Method for rapidly evaluating freeze-thaw resistance of water-based polymer coating material

A water-based polymer and coating material technology, which is applied in the analysis of materials, flow characteristics, strength characteristics, etc., can solve the problems of time-consuming, heavy workload, and affecting the accuracy of experiments, so as to improve the overall quality and save time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

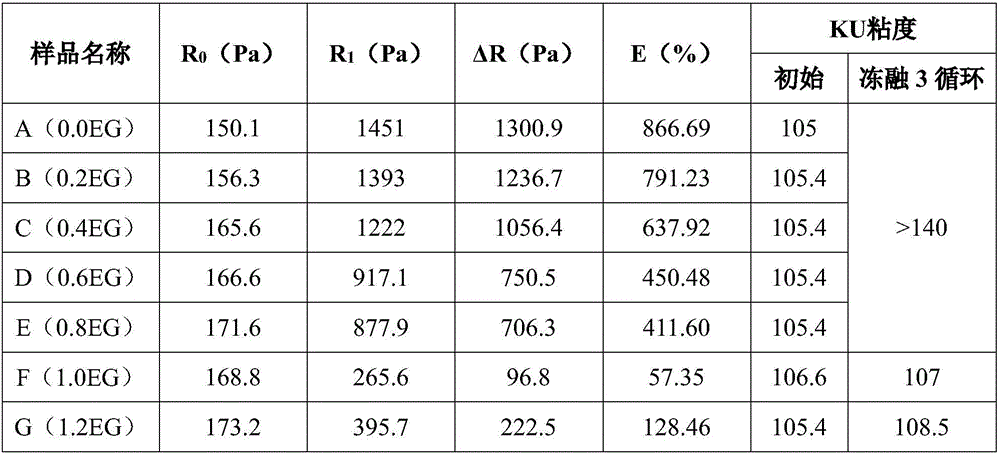

[0036] 1) Select 7 latex paint samples A, B, C, D, E, F, G (the mass fractions of antifreeze ethylene glycol in the samples are respectively: 0, 0.2%, 0.4%, 0.6%, 0.8%, 1.0%, 1.2%, the complete formulations of samples A to G are shown in Table 1), and the amplitude sweep test was carried out to measure the linear viscoelastic region and oscillation test recommended amplitude of the above-mentioned 7 samples at room temperature;

[0037] 2) According to the test conditions calculated in step 1), the initial rheological information of samples A, B, C, D, E, F, and G was measured using the rotational rheometer oscillation mode;

[0038] 3) Use a rheometer to perform a rheometer freeze-thaw cycle. During the cycle, measure the rheological information of the sample during the rheometer freeze-thaw cycle according to the test conditions calculated in step 1), and obtain the sample at Stable time at low temperature;

[0039] 4) After the sample returns to room temperature, according...

Embodiment 2

[0051] 1) Select 7 latex paint samples H, I, J, K, L, M, N (the mass percentages of antifreeze agent propylene glycol in the samples are respectively: 0, 0.2%, 0.4%, 0.6%, 0.8%, 1.0%, 1.2%, the complete formulations of samples H to N are shown in Table 3), and the amplitude sweep test was carried out to measure the linear viscoelastic region and the recommended amplitude of the oscillation test of the above-mentioned 7 samples at room temperature;

[0052] 2) According to the test conditions calculated in step 1), the initial rheological information of samples H, I, J, K, L, M, N is measured using a rotational rheometer oscillation mode;

[0053] 3) Use a rheometer to perform a rheometer freeze-thaw cycle. During the cycle, measure the rheological information of the sample during the rheometer freeze-thaw cycle according to the test conditions calculated in step 1), and obtain the sample at Stable time at low temperature;

[0054] 4) After the sample returns to room temperatu...

Embodiment 3

[0066] 1) Select 4 commercially available latex paint products of the same grade, which are: A company's products 1, 2, 3, B company's products 1, 2, 3, C company's products 1, 2, Nippon's products 1, 2. Carry out the amplitude scanning test to measure the linear viscoelastic region and the recommended amplitude of the oscillation test of the above 10 samples at room temperature;

[0067] 2) According to the test conditions calculated in step 1), the initial rheological information of the above-mentioned 10 samples was measured using the rotational rheometer oscillation mode;

[0068] 3) Use a rheometer to perform a rheometer freeze-thaw cycle. During the cycle, measure the rheological information of the sample during the rheometer freeze-thaw cycle according to the test conditions calculated in step 1), and obtain the sample at Stable time at low temperature;

[0069] 4) After the sample returns to room temperature, according to the test conditions calculated in step 1), use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com