An efficient and stable operation of a bending machine and its hydraulic system

A technology of stable operation and hydraulic system, applied in the field of bending machines, can solve the problems that the control accuracy, control efficiency and stability of the hydraulic system cannot meet the requirements of modern production, and affect the bending quality of plates, so as to reduce the cost of processing and materials. Reduce the effect of installing empty spaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

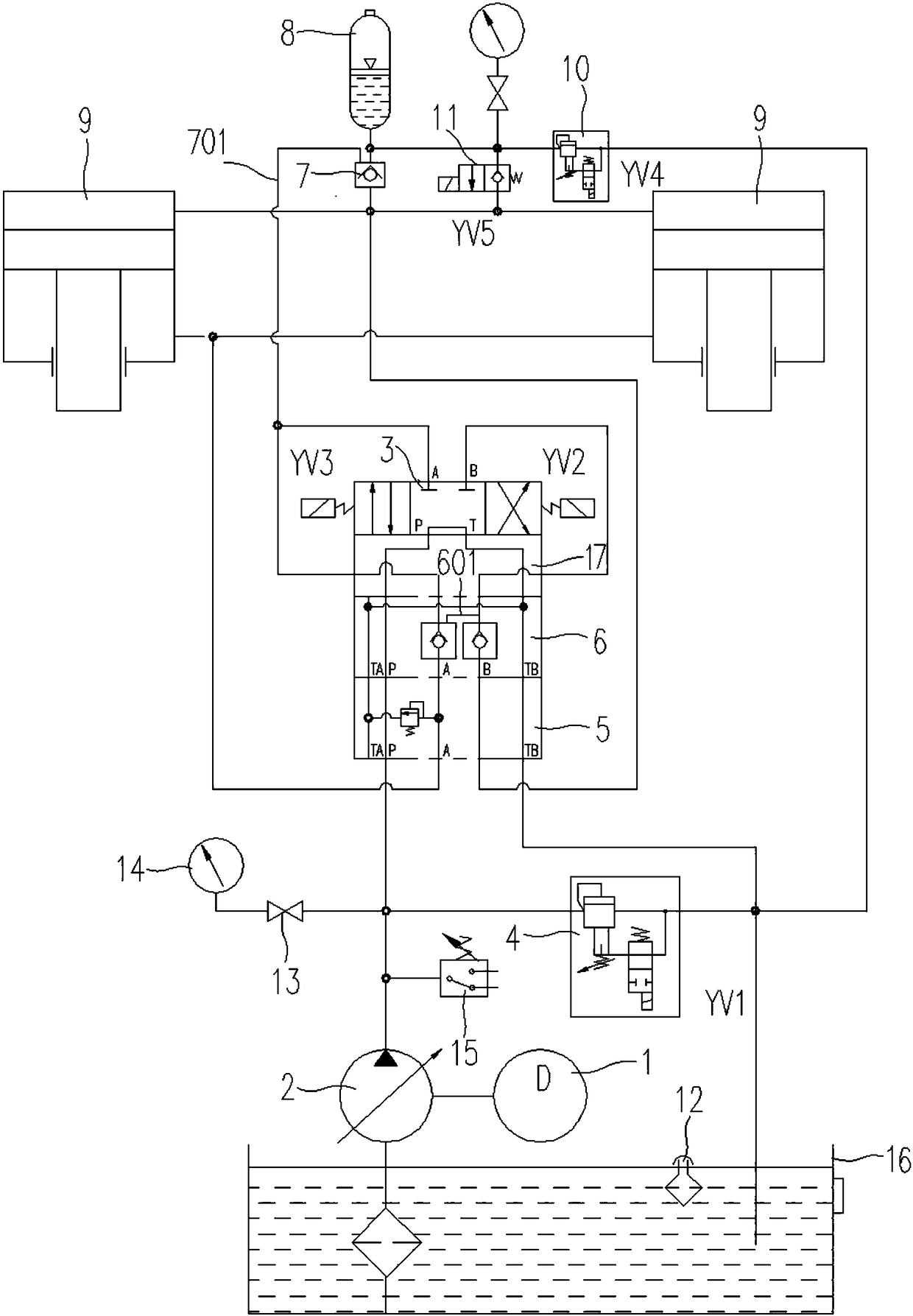

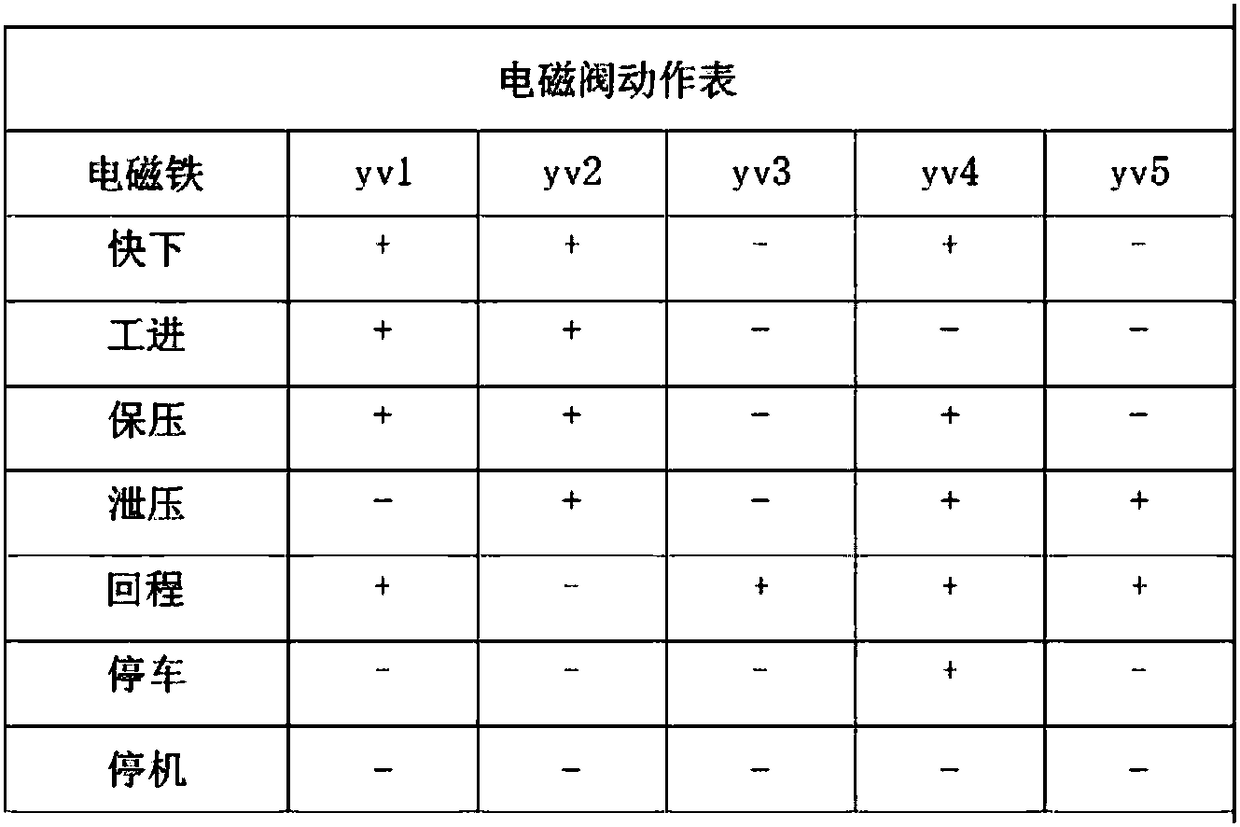

[0033] like figure 1 As shown, a hydraulic system for efficient and stable operation of a bending machine in this embodiment includes an oil pump 2 , an oil tank 16 , a hydraulic cylinder 9 and an accumulator 8 . Wherein, the oil pump 2 is connected with the motor 1, and the oil inlet of the oil pump 2 is connected with the oil tank 16, and the oil outlet of the oil pump 2 is connected with the P port of the three-position four-way electromagnetic reversing valve 3 through a pipeline on the one hand, and on the other hand On the one hand, it is also connected to the oil tank 16 through the electromagnetic overflow valve I4. The T port of the three-position four-way electromagnetic reversing valve 3 is connected to the oil tank 16 through a pipeline, and the A port of the three-position four-way electromagnetic reversing valve 3 is connected to the lower chamber of the hydraulic cylinder 9 through a stacked valve group. The B port of the electromagnetic reversing valve 3 is co...

Embodiment 2

[0037] like figure 1 As shown, a hydraulic system for efficient and stable operation of a bending machine in this embodiment includes an oil pump 2 , an oil tank 16 , a hydraulic cylinder 9 and an accumulator 8 . Wherein, the oil pump 2 is connected with the motor 1, and the oil inlet of the oil pump 2 is connected with the oil tank 16, and the oil outlet of the oil pump 2 is connected with the P port of the three-position four-way electromagnetic reversing valve 3 through a pipeline on the one hand, and on the other hand On the one hand, it is also connected to the oil tank 16 through the electromagnetic overflow valve I4. The T port of the three-position four-way electromagnetic reversing valve 3 is connected to the oil tank 16 through a pipeline, and the A port of the three-position four-way electromagnetic reversing valve 3 is connected to the lower chamber of the hydraulic cylinder 9 through a stacked valve group. The port B leading to the electromagnetic reversing valve...

Embodiment 3

[0054] A bending machine with high efficiency and stable operation in this embodiment, the bending machine includes the hydraulic system described in Embodiment 2, so that each process of bending processing, such as fast lowering, working advance, and pressure maintaining, can be Meet their respective different requirements, realize high speed, stable downward movement, stable work progress, long and stable pressure holding time, thus ensuring the accuracy, stability and bending efficiency of the entire bending process and the processing quality of the plate, so that it can Meet the needs of modern production.

[0055]Usually, the air in the oil tank 16 of the bending machine will flow in and out from the air filter 12 on the oil tank 16 in large quantities as the slider moves up and down at a high speed, but the air in and out of the oil tank 16 in this system is less than 10% of the original, and the oil tank 16 The fluctuation of the internal oil level is small, which great...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com