Composite non-woven fabric based on eggshell inner membrane and black rice and preparing method thereof

A technology of egg shells and non-woven fabrics, which is applied in non-woven fabrics, electrospinning, textiles and papermaking, etc., can solve the problem of low utilization rate of egg shells and their inner membranes, and achieve light and thin paper with good skin-friendly properties , good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

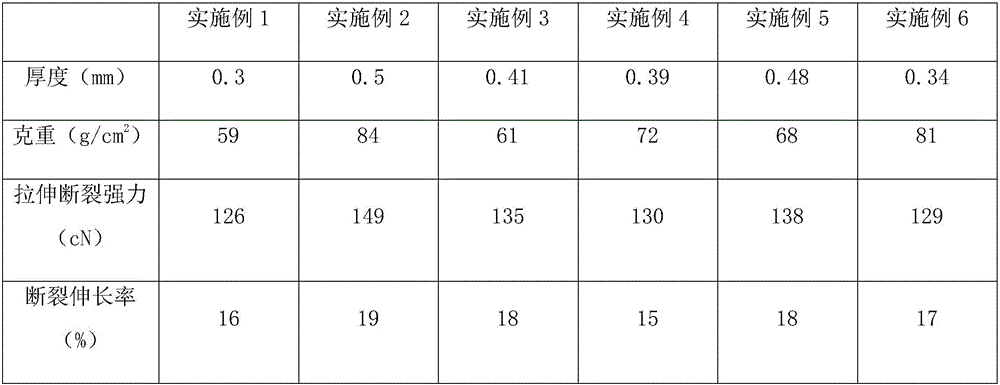

Examples

Embodiment 1

[0029] (1) Remove the eggshell inner membrane from fresh eggs, dissolve 1g of the eggshell inner membrane in 5ml lithium bromide solution, hydrolyze at 50°C for 15 minutes, and dialyze and concentrate to obtain the eggshell inner membrane with a mass fraction of 5%. solution, adding 10% mass fraction of silk protein solution to the eggshell inner membrane solution with a volume ratio of 1:3, fully stirring, concentrating to form a spinning solution, and standing for defoaming, under 15KV voltage, with 0.5ml / h speed electrospinning, the fiber membrane containing eggshell inner membrane was received at 20cm.

[0030] (2) Dry the black rice and grind it into 3 μm black rice starch, add 1 g of black rice starch into 30 ml of ethanol solvent, stir well until mixed evenly, then add 5 ml of 15 g / L sodium hydroxide solution, and heat at 35 ° C Alkaline for 60 minutes, then add 3ml of citric acid and 30ml of silk protein solution with a mass fraction of 10%, fully stir, concentrate to...

Embodiment 2

[0033] (1) Remove the eggshell inner membrane from fresh eggs, dissolve 1g of the eggshell inner membrane in 10ml lithium bromide solution, hydrolyze at 65°C for 30min, and dialyze and concentrate to obtain the eggshell inner membrane with a mass fraction of 10%. Solution, add silk protein solution with a mass fraction of 15% to the eggshell inner membrane solution with a volume ratio of 1:5, stir well, concentrate to form a spinning solution, and after standing for defoaming, under 20KV voltage, use 1ml / The speed of electrospinning is h, and the fiber membrane containing the egg shell inner membrane is received at 25 cm.

[0034] (2) Dry the black rice and grind it into 5 μm black rice starch, add 1 g of black rice starch into 30 ml of ethanol solvent, stir well until the mixture is uniform, then add 10 ml of 20 g / L sodium hydroxide solution, and heat at 40 ° C Alkaline for 90 minutes, then add 3ml citric acid and 40ml silk protein solution with a mass fraction of 15%, fully...

Embodiment 3

[0037] (1) Remove the inner membrane of the eggshell from fresh eggs, dissolve 1g of the inner membrane of the eggshell in 6ml of lithium bromide solution, hydrolyze it at a constant temperature of 55°C for 20min, and obtain the inner membrane of the eggshell with a mass fraction of 7% after dialysis and concentration Solution, add silk protein solution with a mass fraction of 12% to the eggshell inner membrane solution with a volume ratio of 1:4, stir well, concentrate to form a spinning solution, and after standing for defoaming, under 18KV voltage, use 0.7ml / h speed electrospinning, the fibrous membrane containing egg shell inner membrane was received at 22cm.

[0038] (2) Dry the black rice and grind it into 4 μm black rice starch, add 1 g of black rice starch into 30 ml of ethanol solvent, stir well until mixed evenly, then add 8 ml of 17 g / L sodium hydroxide solution, and heat at 36 ° C Alkalinize for 70 minutes, then add 3ml of citric acid and 35ml of silk protein soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com