A kind of nano copper regenerated cellulose fiber and preparation method thereof

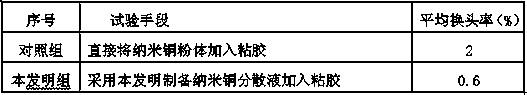

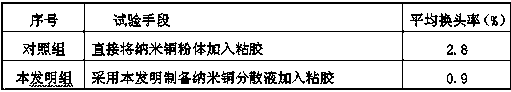

A technology of regenerated cellulose and nano-copper, applied in the fiber field, can solve the problems of low physical and mechanical properties of fibers, easy shedding, high loss rate, etc., and achieve the effect of ensuring antibacterial effect, not easy to shed, and reducing head replacement rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

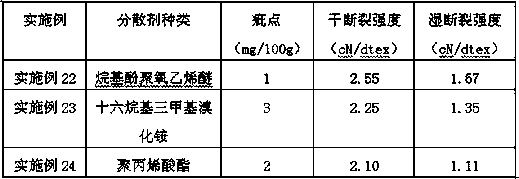

Examples

Embodiment 1

[0041] Example 1 Preparation of Nano Copper Regenerated Cellulose Fibers

[0042] Nano copper dispersion preparation:

[0043] (1) Suspension preparation: Add nano-copper powder into deionized water with a hardness lower than 1. The purity of the nano-copper powder is 99.5%, particle size D90: 1um, specific surface area: 4.0m 2 / g, the conductivity of the deionized water: 500us / cm, made of nano-copper suspension, the addition ratio of nano-copper powder is 5g / 100ml, and then add 1 wt% hexadecyl trimethyl bromide Ammonium (CTAB) dispersant, stir well.

[0044] (2) Ultrasonic treatment: Ultrasonic treatment was used for 15 minutes, and the pH was adjusted to 7.5 with NaOH and acetic acid to prepare a 5 wt% nano-copper dispersion for use.

[0045] Preparation of spun viscose: cellulose pulp is used as raw material, and the spun viscose collagen solution is obtained through impregnation, pressing, crushing, aging, yellowing, filtering, aging and degassing.

[0046] Ball milling...

Embodiment 2

[0055] Example 2 Preparation of Nano Copper Regenerated Cellulose Fibers

[0056] Nano copper dispersion preparation:

[0057] (1) Suspension preparation: Add nano-copper powder into deionized water with a hardness lower than 1. The nano-copper powder has a purity of 99.6%, a particle size D90 of 0.8um, and a specific surface area of 4.0m 2 / g, the conductivity of the deionized water: 450us / cm, made of nano-copper suspension, the addition ratio of nano-copper powder is 10g / 100ml, to which 2 wt% cetyl trimethyl bromide is added Ammonium (CTAB) dispersant, stir well.

[0058] (2) Ultrasonic treatment: Sonicate for 25 minutes, adjust the pH to 8.0 with NaOH and acetic acid, and prepare a 10 wt% nano-copper dispersion for use.

[0059] Preparation of spun viscose: cellulose pulp is used as raw material, and the spun viscose collagen solution is obtained through impregnation, pressing, crushing, aging, yellowing, filtering, aging and degassing.

[0060] Ball milling: The prepa...

Embodiment 3

[0069] Example 3 Preparation of Nano Copper Regenerated Cellulose Fibers

[0070] Nano copper dispersion preparation:

[0071] (1) Suspension preparation: Add nano-copper powder into deionized water with a hardness lower than 1. The nano-copper powder has a purity of 99.9%, particle size D90: 0.89um, and specific surface area: 4.5m 2 / g, the conductivity of the deionized water: 400us / cm, made of nano-copper suspension, the addition ratio of nano-copper powder is 15g / 100ml, to which 3 wt% cetyl trimethyl bromide is added Ammonium (CTAB) dispersant, stir well.

[0072] (2) Ultrasonic treatment: Ultrasonic treatment for 30 min, adjust the pH to 8.8 with NaOH and acetic acid, and prepare a 15 wt% nano-copper dispersion for use.

[0073] Preparation of spun viscose: cellulose pulp is used as raw material, and the spun viscose collagen solution is obtained through impregnation, pressing, crushing, aging, yellowing, filtering, aging and degassing.

[0074] Ball milling: The prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com