Pollution prevention and control method for ethanol consumption bacteria in ethanol producing genetic engineering cyanobacteria culture system

A culture system and genetic engineering technology, applied in the field of pollution prevention and control for ethanol-consuming bacteria, can solve problems such as ethanol bio-pollution, achieve the effect of improving carbon source capture efficiency and reducing carbon source capture costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

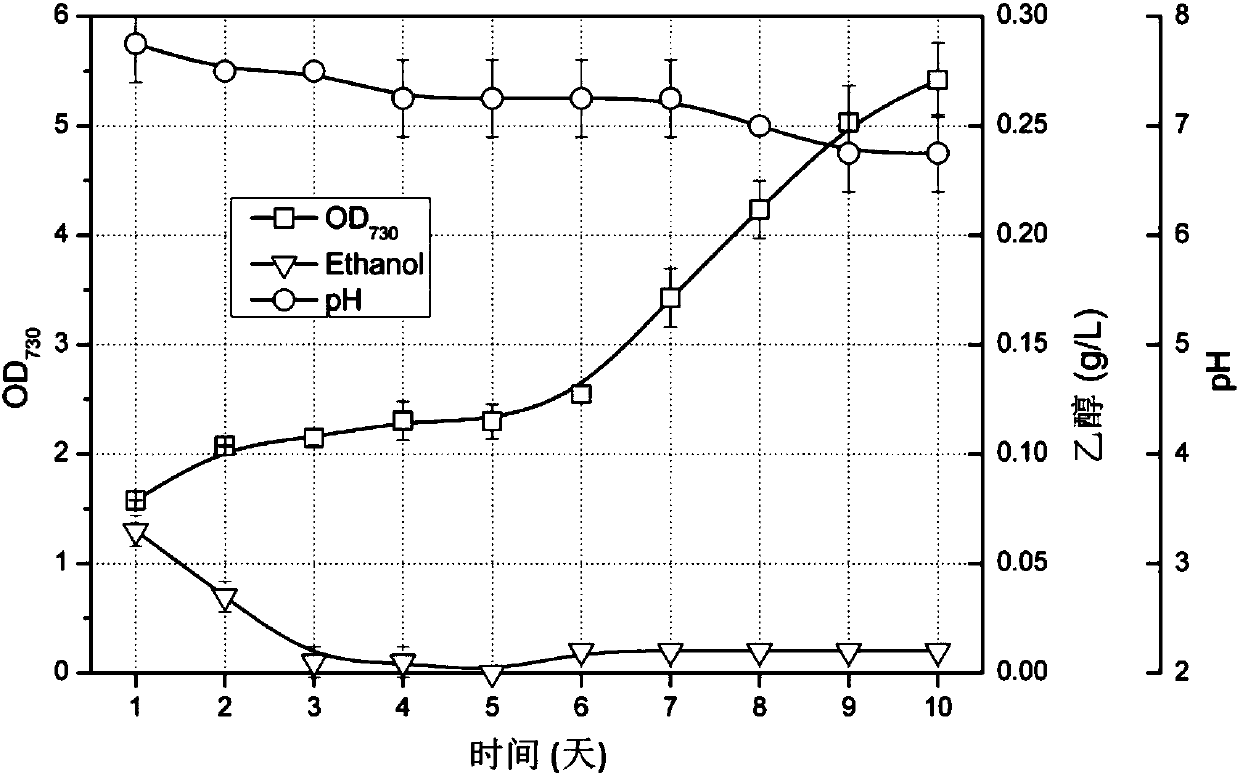

[0016] Example 1: In this embodiment, the pollution control method of ethanol-consuming bacteria in the ethanol-producing genetically engineered cyanobacteria culture system is applied in an indoor glass column photoreactor.

[0017] The specific method is to add 600ml of BG11 medium with an initial sodium bicarbonate concentration of 180mmol / L in an 800ml glass column photoreactor, and directly insert the genetically engineered Synechocystis sp. -2 the s -1 , cultured at 30°C, the pH value in the culture solution gradually increased to 11.0 as the algae cells grew with sodium bicarbonate, and CO 2 The gas adjusted the pH value to maintain at 11.0±0.5, and the product ethanol gradually accumulated while the algae cells grew.

[0018] The genetically engineered cyanobacteria is an ethanol-producing mutant strain of Synechocystis sp. PCC 6803, which was published by Gao Zhengxu et al. in Energy&Environmental Science magazine in May 2012 (Gao ZX, Zhao H, Li ZM, Tan XM, Lu XF: P...

Embodiment 2

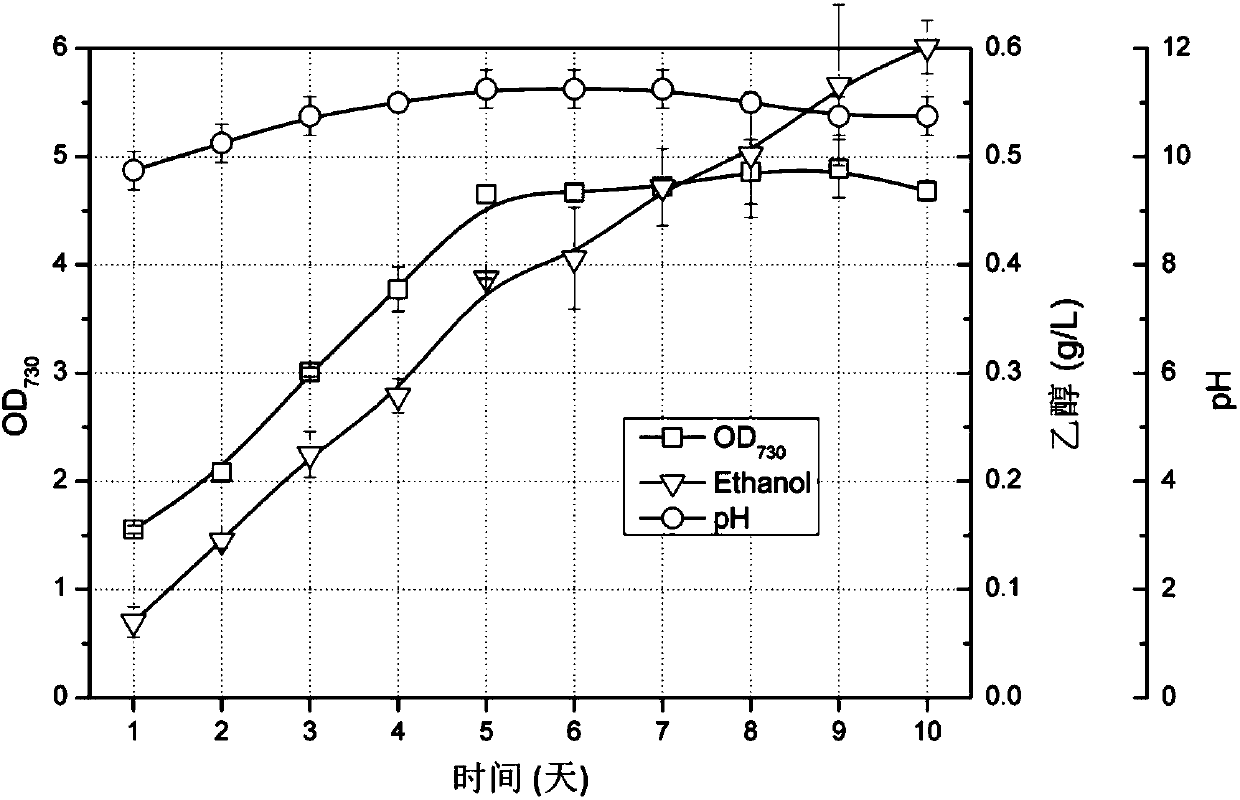

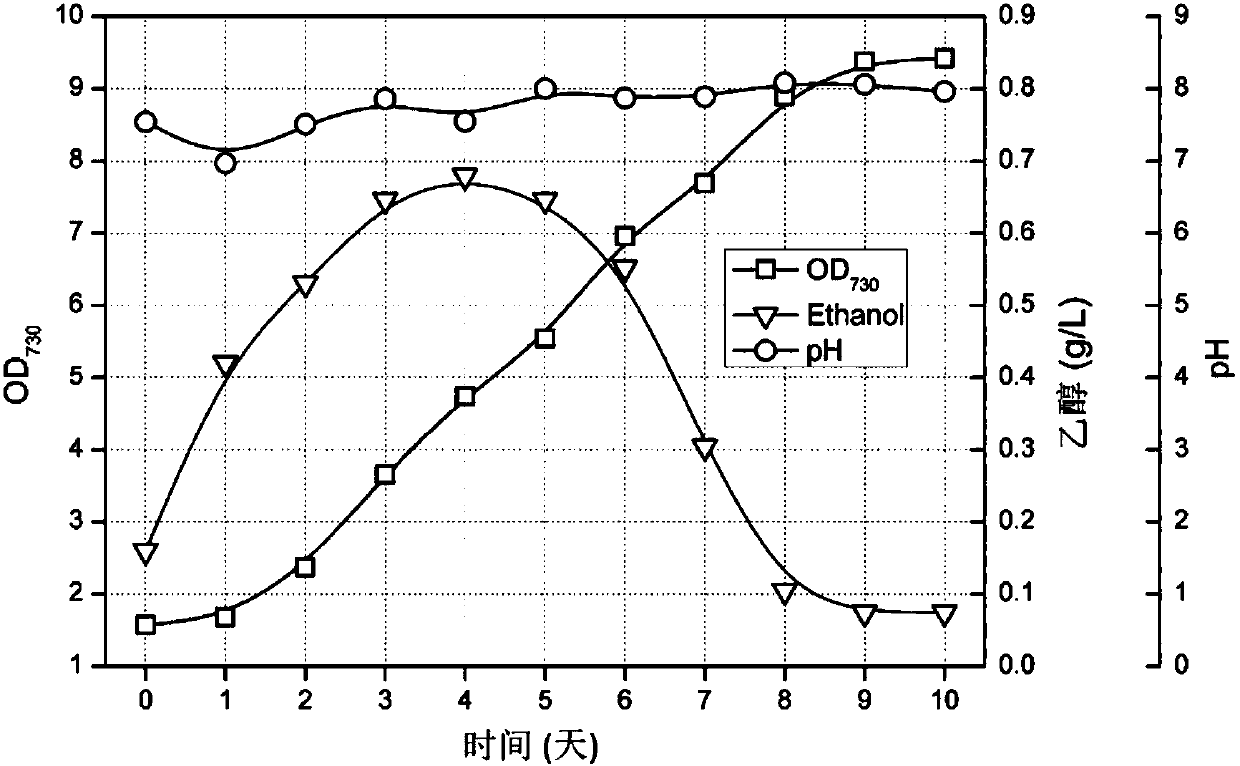

[0021] Example 2: In this embodiment, the pollution control method of ethanol-consuming bacteria in the ethanol-producing genetically engineered cyanobacteria culture system is applied in an outdoor film-hanging bag-type photoreactor.

[0022] In an 8L film hanging bag photoreactor, add 6L tap water to prepare a BG11 medium with an initial sodium bicarbonate concentration of 180mmol / L without high temperature sterilization, and insert genetically engineered cyanobacteria, under the conditions of outdoor natural light intensity and temperature After culturing, the pH value in the culture solution gradually increased to 11.0 as the algae cells grew using sodium bicarbonate as a carbon source, and CO 2 The gas adjusted the pH value to maintain at 11.0±0.5, and the product ethanol gradually accumulated while the algae cells grew.

[0023] The genetically engineered cyanobacteria are the same as in Example 1.

[0024] at 5% CO 2 Conditions are control experiments. The culture co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com