Fluorescent lamp amalgam welding device and welding method

A welding device and fluorescent lamp technology, applied in laser welding equipment, welding equipment, metal processing and other directions, can solve the problems of low welding efficiency and unstable welding quality, and achieve the effects of high welding efficiency, improved welding quality, and convenient and quick removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

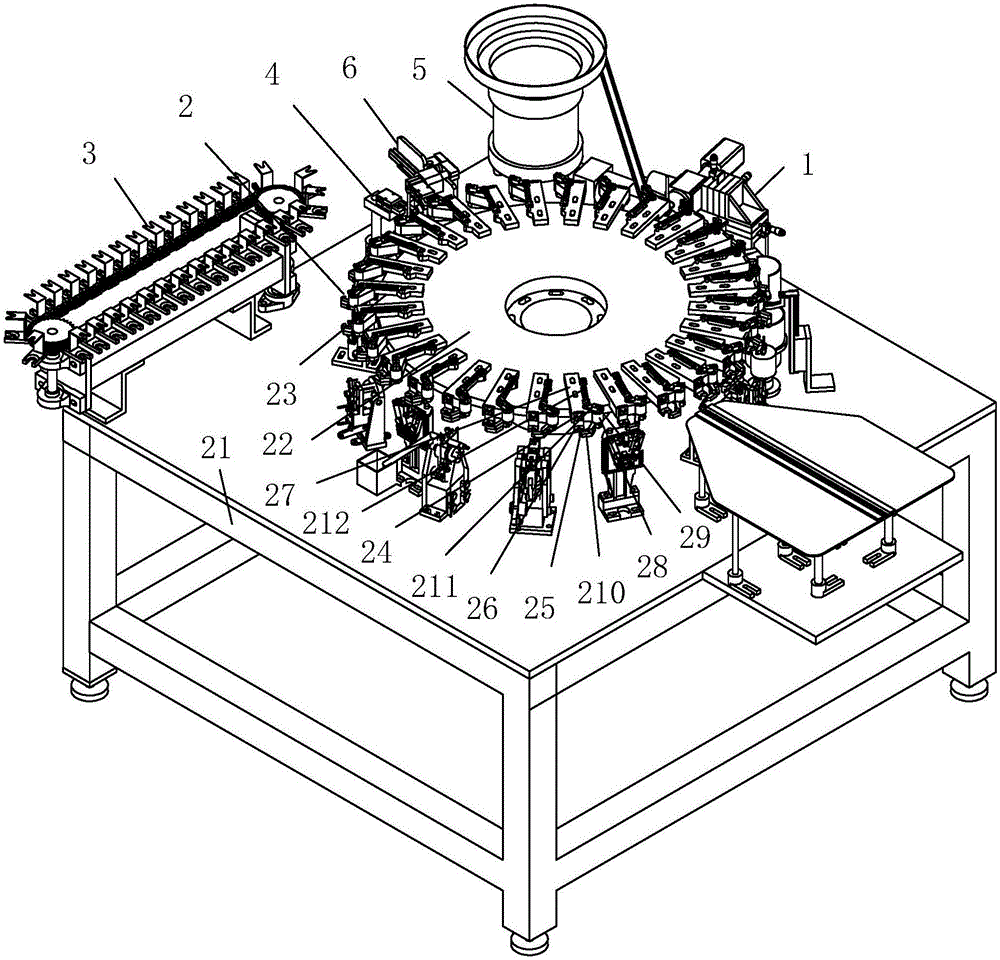

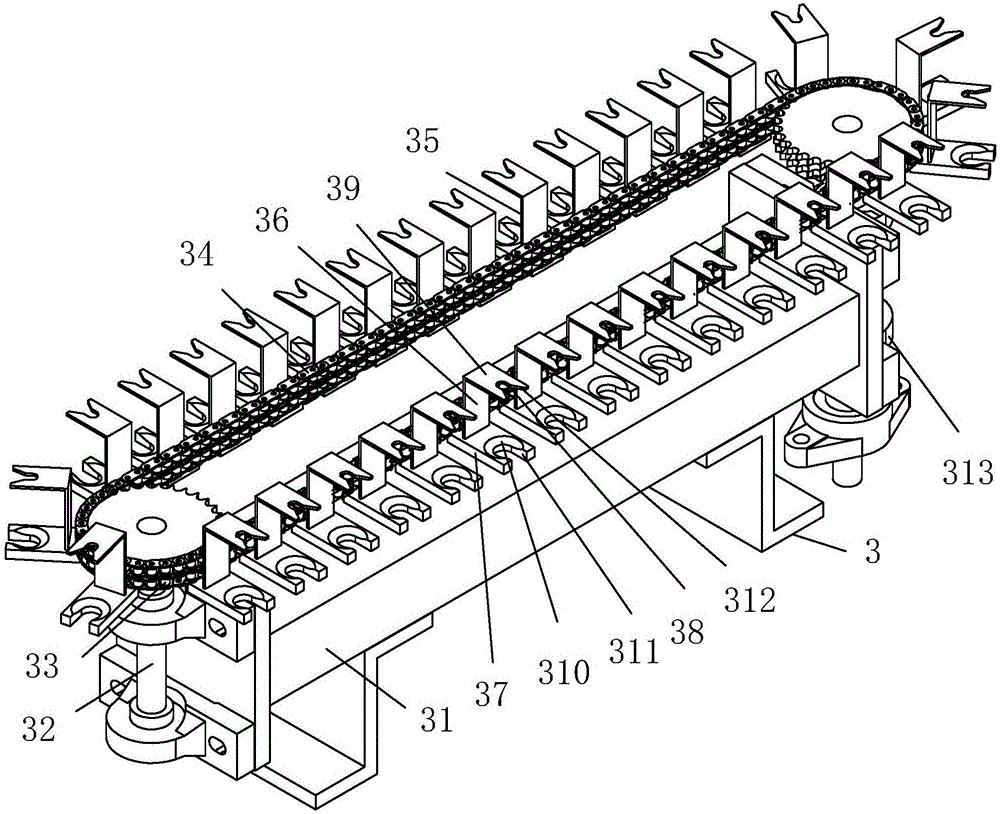

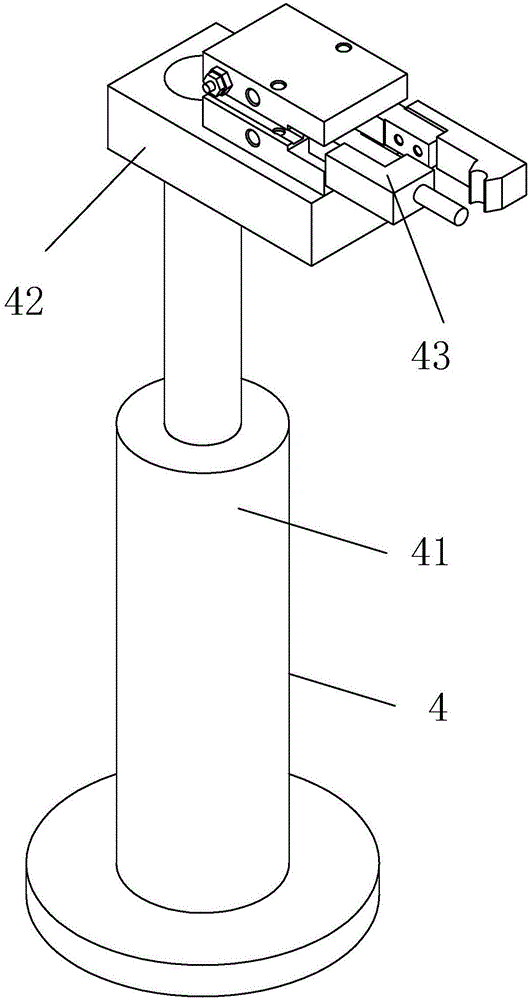

[0025] as attached figure 1 to attach Figure 7Shown: an amalgam welding device for fluorescent lamps, including: a welding machine, a multi-station welding seat 2, a stem delivery mechanism 3, and a stem entry mechanism located between the stem delivery mechanism 3 and the multi-station welding seat 2 4. The amalgam ring feeding mechanism 5 and the weldment blanking mechanism 6.

[0026] The multi-station welding seat 2 includes: a frame 21, a support turntable 22 whose lower end is pivotally connected to the frame 21, twenty-eight stem welding support frames 23 uniformly distributed along the circumference of the support turntable 22, and a support turntable drive device The stem welding support frame 23 includes: a vertical plate 24 positioned at the outer side of the support turntable 22, the outer end is provided with a welding positioning gap 25 and a horizonta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com