Cu-SSZ-13 molecular sieve based catalyst adopting core-shell structure as well as preparation and application of catalyst

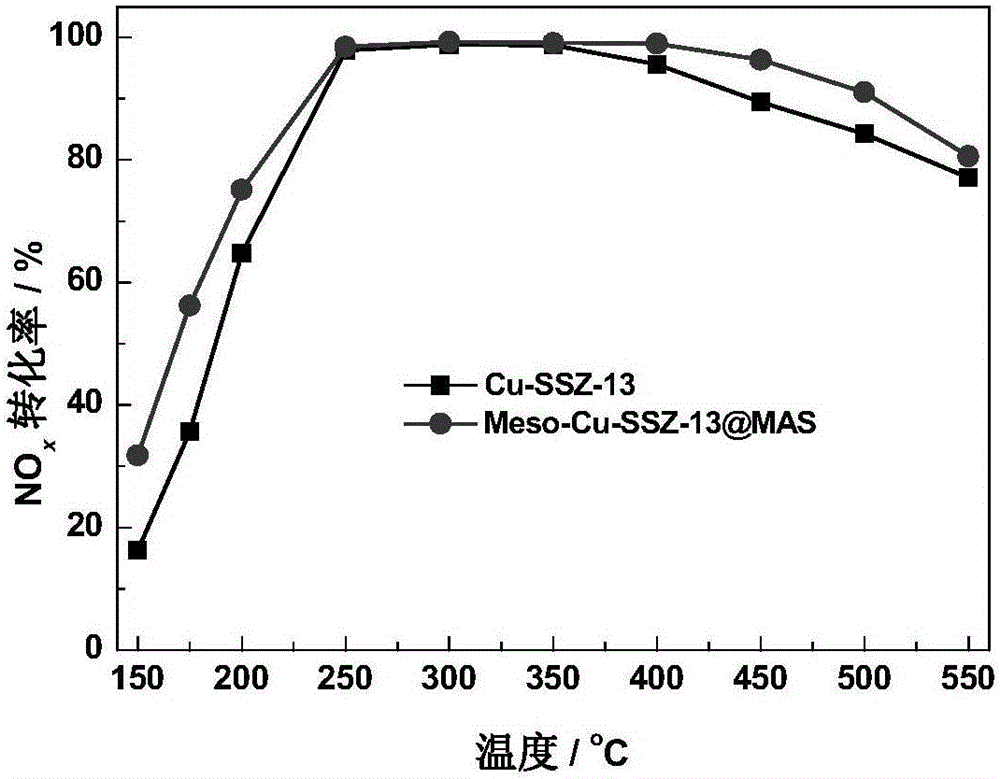

A cu-ssz-13, core-shell structure technology, applied in molecular sieve catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the limitations of the practical application of Cu-SSZ-13 molecular sieve catalysts and low low-temperature catalytic activity. , the reduction of catalytic activity, etc., to achieve the effect of improving hydrothermal stability and anti-hydrocarbon poisoning ability, high activity, and broadening the working temperature window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Add 1 g of SSZ-13 molecular sieve into 100 mL of 0.1 mol / L NaOH solution, and treat it at 35°C for 2 hours, at this time, mesoporous SSZ-13 molecular sieve can be obtained.

[0030] (2) Add deionized water and 100mL ethanol solution containing 2g P123 to the above suspension, and adjust its pH value to about 5 with acid solution.

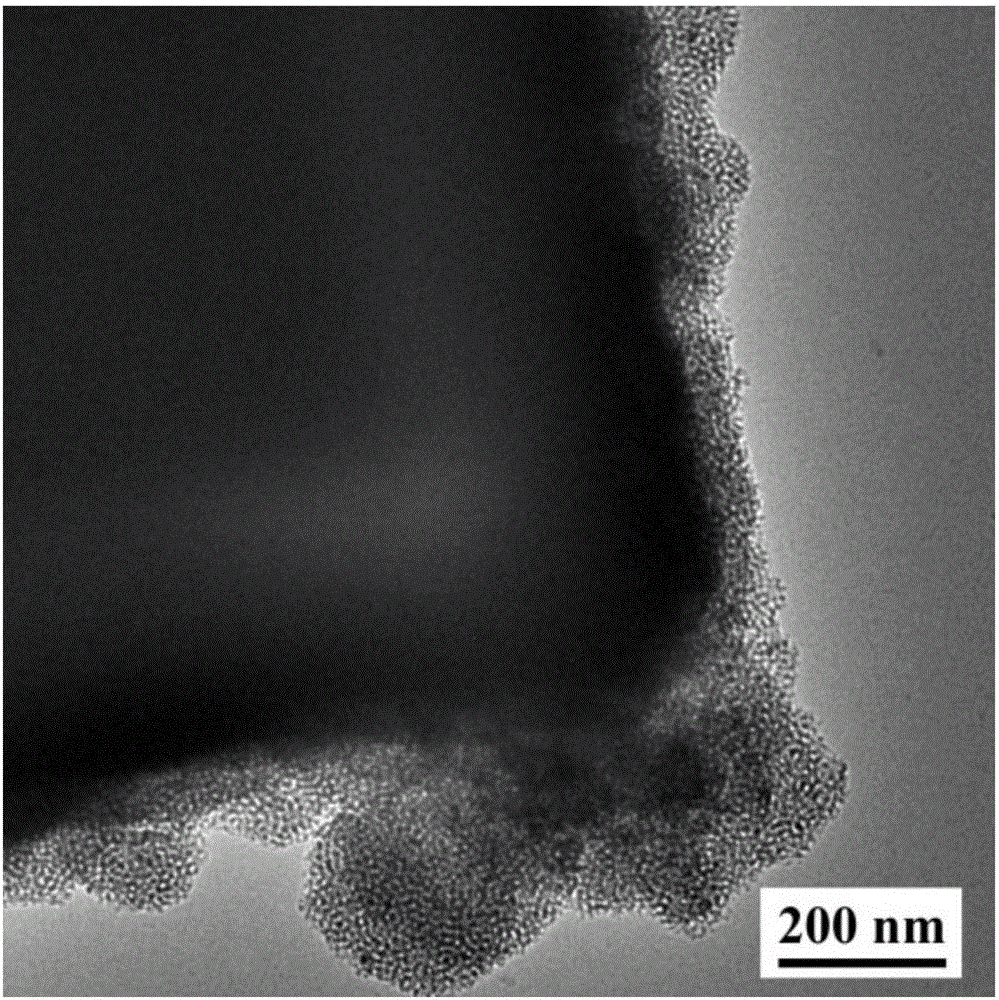

[0031] (3) React the above solution at 35° C. for 48 hours, and then raise it to 70° C. for 24 hours to obtain a molecular sieve carrier with a core-shell structure. figure 1 is its electron micrograph, by figure 1 It can be seen that it is SSZ-13 molecular sieve (Meso-SSZ-13@MAS) with core-shell structure.

[0032] (4) The obtained product was washed alternately with deionized water and ethanol solution respectively, then dried at 100° C. for 12 hours, and then calcined at 550° C. for 6 hours.

[0033](5) The corresponding catalyst is prepared by an aqueous solution ion exchange method. Add 1 g of core-shell structure SSZ-13 molecular...

Embodiment 2

[0036] (1) Add 1 g of SSZ-13 molecular sieve into 50 mL of 0.2 mol / L NaOH solution, and treat it at 35°C for 1 hour, at this time, the mesoporous SSZ-13 molecular sieve can be obtained.

[0037] (2) Add deionized water and 150mL ethanol solution containing 3g P123 to the above suspension, and adjust its pH value to about 5.5 with acid solution.

[0038] (3) React the above solution at 35° C. for 48 hours, and then raise it to 70° C. for 24 hours to obtain a molecular sieve carrier with a core-shell structure.

[0039] (4) The obtained product was washed alternately with deionized water and ethanol solution respectively, then dried at 100° C. for 12 hours, and then calcined at 550° C. for 6 hours.

[0040] (5) The corresponding catalyst is prepared by an aqueous solution ion exchange method. Add 1 g of core-shell structure SSZ-13 molecular sieve to 100 mL of 0.1 mol / L ammonium nitrate solution, stir at 80 ° C for 12 h, then filter and wash with deionized water to obtain ammoni...

Embodiment 3

[0042] (1) Add 1 g of SSZ-13 molecular sieve into 20 mL of 0.3 mol / L NaOH solution, and treat it at 35° C. for 0.5 h, at which point mesoporous SSZ-13 molecular sieve can be obtained.

[0043] (2) Add deionized water and ethanol solution containing CTAB to the above suspension, and adjust its pH value to about 5 with acid solution.

[0044] (3) React the above solution at 35° C. for 48 hours, and then raise it to 70° C. for 24 hours to obtain a molecular sieve carrier with a core-shell structure.

[0045] (4) The obtained product was washed alternately with deionized water and ethanol solution respectively, then dried at 100° C. for 12 hours, and then calcined at 550° C. for 6 hours.

[0046] (5) The corresponding catalyst is prepared by a solid-state ion exchange method. Add the core-shell structure SSZ-13 molecular sieve to the ammonium nitrate solution, use 100mL of 0.01mol / L ammonium nitrate solution for 1g molecular sieve, stir at 80°C for 12h, then filter and wash with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com