Combined system and method for processing oil gas generated by pyrolysis of low rank coal

A technology for pyrolysis of oil and gas and low-rank coal, which is applied in the petroleum industry, hydrotreating process, and hydrocarbon oil treatment, and can solve the problem that heavy components cannot be fully utilized, coal tar has a low degree of lightening, and tar and water High degree of emulsification, to avoid secondary condensation coke, save hydrogen production costs, and avoid phenolic sewage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

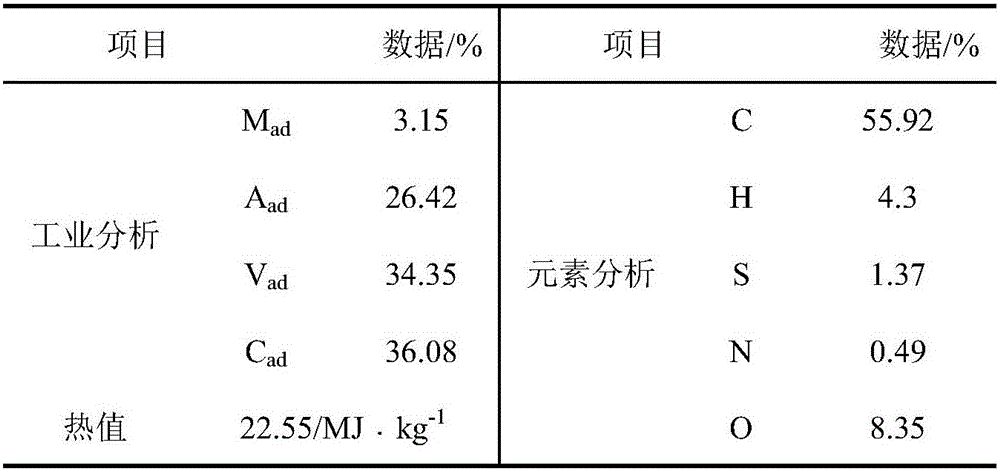

Embodiment 1

[0097] The pyrolysis oil and gas are dedusted by the dust removal unit and then cooled to 420℃ in the pyrolysis oil and gas quench unit. After being stabilized by the stabilizer, they enter the atmospheric distillation tower at 400℃. The pyrolysis gas is separated at the top, and the naphtha fraction and diesel fraction are separated in the side line. , Heavy oil at the bottom of the atmospheric tower and primary cooled heavy oil are used as the feed of the suspended bed hydrocracking unit. The suspended bed hydrocracking reaction temperature is 420℃, the pressure is 12Mpa, the catalyst is molybdenum naphthenate, and the metal content is 80μg. / g, the vulcanizing agent is sublimated sulfur powder, the adding amount is 80μg / g, the cutting temperature of the light and heavy components in the vacuum distillation is 520℃, the residue oil gasification assistant is calcined dolomite, the adding amount is 0.3%, and the gasification agent is water Steam and oxygen, the ratio of oxygen t...

Embodiment 2

[0099] The pyrolysis oil and gas are dedusted by the dust removal unit and then cooled to 440℃ in the pyrolysis oil and gas quench unit. After being stabilized by the stabilizer, they enter the atmospheric distillation tower at 420℃. The pyrolysis gas is separated at the top, and the naphtha fraction and diesel fraction are separated in the side line. , The heavy oil at the bottom of the atmospheric tower and the first-cooled heavy oil are used as the feed of the suspended bed hydrocracking unit. The suspended bed hydrocracking reaction temperature is 450°C and the pressure is 18Mpa. Heterogeneous catalyst is added, and the mixture of laterite nickel and red mud is added. The amount is 0.5%, the homogeneous catalyst is a metal tungsten complex, measured by the metal element, the metal content is 50μg / g, the vulcanizing agent is sublimated sulfur powder, the addition amount is 100μg / g, and the cutting temperature of light and heavy components under reduced pressure is 550℃, resid...

Embodiment 3

[0101] The pyrolysis oil and gas are dedusted by the dust removal unit and then cooled to 460℃ in the pyrolysis oil and gas quench unit. After being stabilized by the stabilizer, they enter the atmospheric distillation tower at 450℃. The pyrolysis gas is separated at the top and the naphtha fraction and diesel fraction are separated in the side line. , The heavy oil at the bottom of the atmospheric column and the primary cooled heavy oil are used as the feed of the suspended bed hydrocracking unit. The suspended bed hydrocracking reaction temperature is 475℃, the pressure is 24Mpa, and the heterogeneous catalyst fixed bed hydrogenation waste agent is added, and the addition amount is 3% , The vulcanizing agent is sublimated sulfur powder, the cutting temperature of the light and heavy components in vacuum distillation is 565℃, the residue oil and gasification auxiliary is selected from calcined clay ore, the addition amount is 1.5%, the gasification agent is water vapor and oxyge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com