A kind of soft environment-friendly multifunctional decorative paper and preparation method thereof

A decorative paper, multi-functional technology, applied in chemical instruments and methods, lamination devices, paper/cardboard layered products, etc., can solve the problem of incomplete decomposition of chemical foaming agents, affecting the performance of decorative paper products, decorative The problem of single type of paper, etc., can avoid the damage of structure and performance, save the glue coating process, and remove the effect of solvent pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

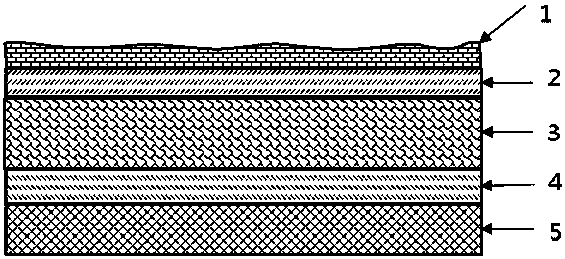

[0054] The substrate layer 5 is a non-woven fabric formed of 70% pulp and 30% polyester, with a thickness of 0.1 mm.

[0055] Thermal composite layer A2 is polyethylene resin (Zhongyuan Petrochemical, model: 7050).

[0056] Foamed sheet layer 3 uses commercially available polyolefin (polyethylene) foamed sheet (Changzhou Sanhe Plastics, model L-4500), and the apparent density of foamed sheet layer 3 is 0.02g / cm 3 , The average pore diameter is 180 μm, the compressive stress at 50% compression is 50 kPa, and the thickness is 0.5 mm.

[0057] Thermal composite layer B4 is polypropylene resin (Yangzi Petrochemical, model: F401).

[0058] The thermal lamination layer B4, the foam sheet layer 3 and the base material layer 5 are thermally laminated with a hot-melt laminating machine, and the thermal lamination temperature is 110°C, and the foam sheet layer 3 and the thermal lamination layer A2 are laminated with a flame laminating machine , where the fire row device is set in 4 ro...

Embodiment 2

[0061] The substrate layer 5 is made of pure paper with a thickness of 0.5 mm.

[0062] Thermal composite layer A2 is ethylene-vinyl acetate copolymer (French Atofina, model: 2805).

[0063] Foamed sheet layer 3 uses commercially available polyurethane foamed sheet (mountain adhesive, model LM), and the apparent density of foamed sheet layer is 0.20g / cm 3 , The average pore diameter is 50 μm, the compressive stress at 50% compression is 230 kPa, and the thickness is 2 mm.

[0064] Thermal composite layer B4 is ethylene-vinyl acetate copolymer (French Atofina, model: 2805).

[0065] Thermal lamination layer B4, foam sheet layer 3 and substrate layer 5 are thermally laminated using a hot-melt lamination machine, and the thermal lamination temperature is 150°C, and the foam sheet layer 3 and thermal lamination layer A2 are laminated by a flame lamination machine , the thermal compound machine is a flame compound machine, wherein the fire row device is set to 8 rows, the flame p...

Embodiment 3

[0067] The substrate layer 5 is made of aluminum foil with a thickness of 0.2 mm.

[0068] Thermal composite layer A is polypropylene resin (Maoming Petrochemical, model T36F).

[0069] The foamed sheet layer uses commercially available neoprene foamed sheet (Yibao polymer, model YB-3025), and the apparent density of the foamed sheet layer is 0.15g / cm 3 , The average pore diameter is 300 μm, the compressive stress at 50% compression is 200 kPa, and the thickness is 3 mm.

[0070] Thermal composite layer B is polypropylene resin (Maoming Petrochemical, model T36F).

[0071] The thermal lamination layer B4, the foam sheet layer 3 and the base material layer 5 are thermally laminated with a hot-melt lamination machine, and the thermal lamination temperature is 230°C, and the foam sheet layer 3 and the thermal lamination layer A2 are laminated with a flame lamination machine , where the fire row device is set in 6 rows, the flame ports are arranged on the fire row device in rows...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com