Powdery casting coating as well as preparation method and use method thereof

A casting coating and powdery technology, which is applied to casting molding equipment, coatings, casting molds, etc., can solve the problems of separation of alcohol, aggregate and additives, poor solubility of additives and alcohol, and difficulty in obtaining qualified coatings. Achieve good suspension stability, excellent adhesion, and avoid accidents such as fire or explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

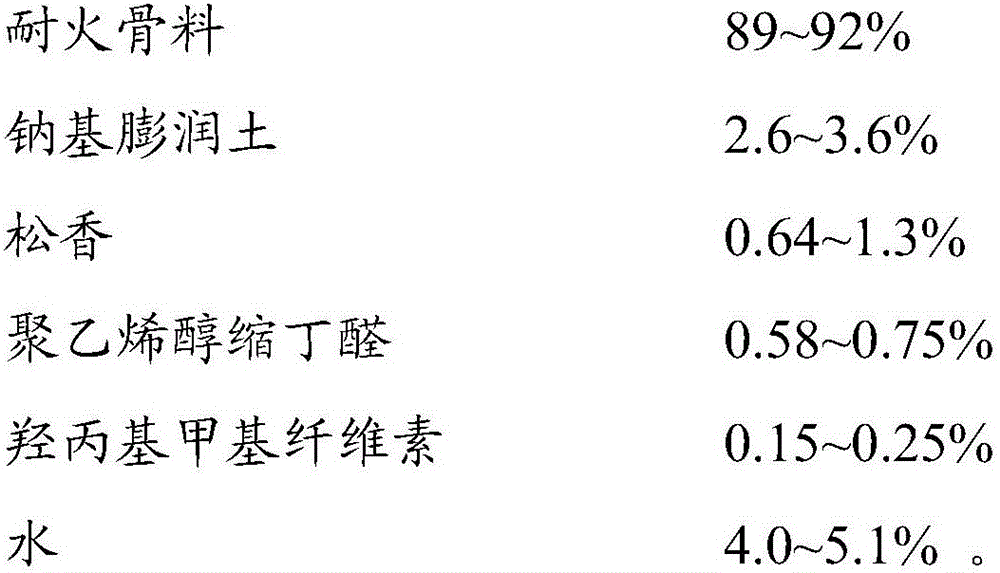

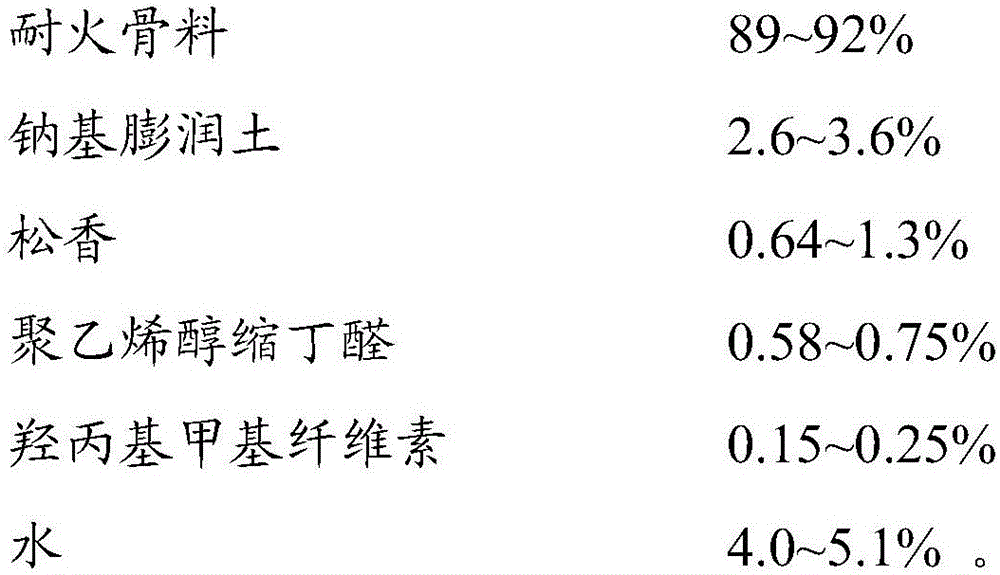

[0029] The powder casting coating of the present embodiment is composed of the following components by weight percentage: 91% of refractory aggregate, 2.7% of sodium bentonite, 0.9% of rosin, 0.72% of polyvinyl butyral, and 0.18% of hydroxypropyl methylcellulose %, water 4.5%. Among them, the particle size of the refractory material is selected as 325 mesh; the viscosity of hydroxypropyl methylcellulose is selected as 10mpa.s; the particle size of polyvinyl butyral is selected as 800 mesh, and the viscosity is 20mpa.s; the rosin is selected as maleic rosin , the particle size is 400 mesh; the particle size of sodium bentonite is selected as 600 mesh.

[0030] Preparation Process:

[0031] (1) Prepare 91 kilograms of refractory aggregate: weigh 30 kilograms of zircon powder, 21 kilograms of corundum powder, and 40 kilograms of bauxite, and mix them for later use;

[0032] (2) Take by weighing 2.7 kilograms of sodium bentonite, 0.9 kilograms of rosin, 0.72 kilograms of polyvin...

Embodiment 2

[0042] The powder casting coating of this embodiment is composed of the following components by weight percentage: 90% of refractory aggregate, 3.6% of sodium bentonite, 1.3% of rosin, 0.75% of polyvinyl butyral, 0.15% of hydroxypropyl methylcellulose %, water 4.2%. Among them, the particle size of the refractory material is selected as 325 mesh; the viscosity of hydroxypropyl methylcellulose is selected as 15mpa.s; the particle size of polyvinyl butyral is selected as 700 mesh, and the viscosity is 5mpa.s; the rosin is selected as maleic rosin , the particle size is 500 mesh; the particle size of sodium bentonite is selected as 700 mesh.

[0043] Preparation Process:

[0044] (1) Prepare 90 kg of refractory aggregate: weigh 30 kg of zircon powder, 20 kg of mullite powder, 20 kg of corundum powder, and 20 kg of bauxite, and mix them for later use;

[0045] (2) Take by weighing 3.6 kilograms of sodium bentonite, 1.3 kilograms of rosin, 0.75 kilograms of polyvinyl butyral, and...

Embodiment 3

[0055] The powder casting coating of this embodiment is composed of the following components by weight percentage: 89% of refractory aggregate, 3.6% of sodium bentonite, 1.3% of rosin, 0.75% of polyvinyl butyral, 0.25% of hydroxypropyl methylcellulose %, water 5.1%. Among them, the particle size of the refractory material is selected as 325 mesh; the viscosity of hydroxypropyl methylcellulose is selected as 5mpa.s; the particle size of polyvinyl butyral is selected as 600 mesh, and the viscosity is 3mpa.s; the rosin is selected as maleic rosin , the particle size is 500 mesh; the sodium bentonite particle size is selected as 800 mesh.

[0056] Preparation Process:

[0057] (1) Prepare 89 kilograms of refractory aggregate: take 89 kilograms of bauxite for subsequent use;

[0058] (2) Take by weighing 3.6 kilograms of sodium bentonite, 1.3 kilograms of rosin, 0.75 kilograms of polyvinyl butyral, and 0.25 kilograms of hydroxypropyl methylcellulose;

[0059] (3) Mix the powders...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com