Solid polymer electrolyte and preparation method thereof

A solid polymer and electrolyte technology, applied in solid electrolytes, non-aqueous electrolytes, circuits, etc., can solve the problems of low conductivity of electrolytes and poor mechanical properties of polymer electrolytes, achieve low glass transition temperature, promote migration, improve The effect of ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation method of above-mentioned solid polymer electrolyte, comprises the steps:

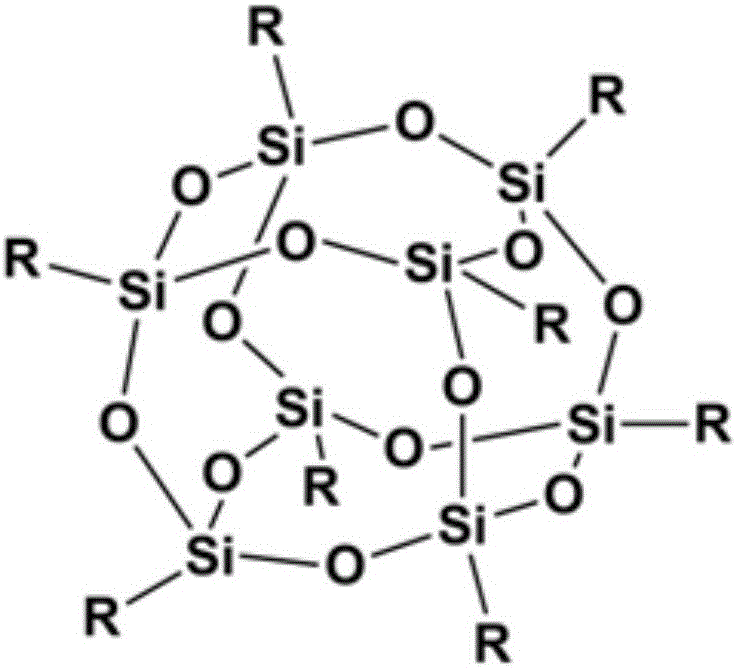

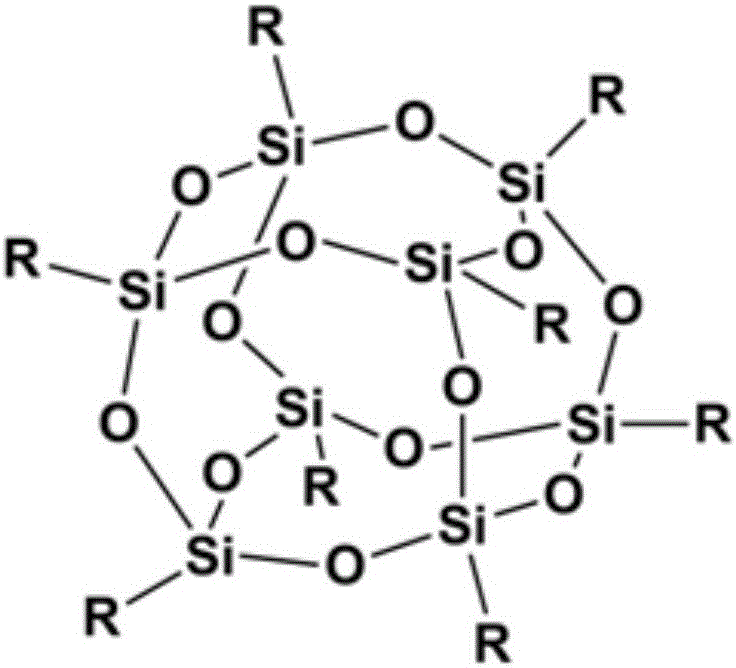

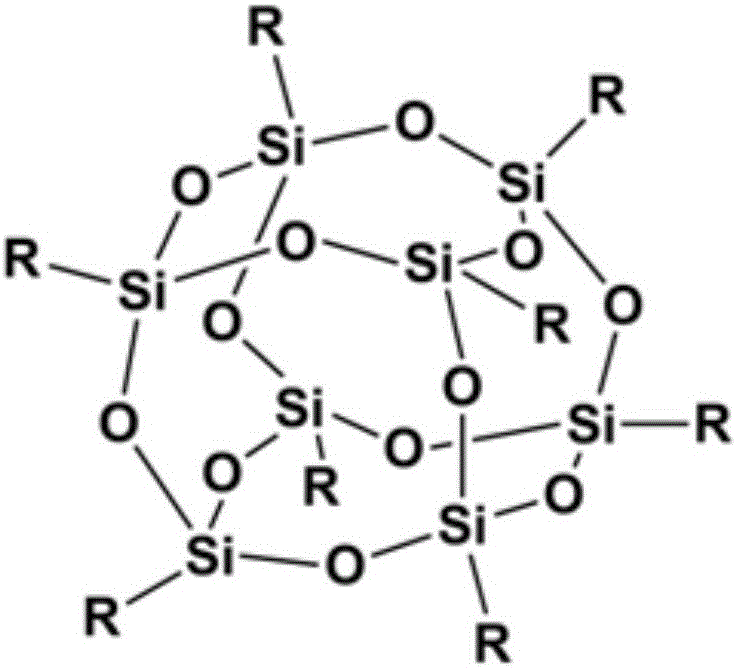

[0038] Provide the following components by weight: 1 part of nitrile rubber, 0.02-0.8 parts of octa(polyethylene glycol)-cage polysilsesquioxane, 0.1-3 parts of lithium salt; also provide a solvent for dissolving nitrile rubber , wherein every 1g of nitrile rubber corresponds to 15ml-25ml of solvent, nitrile rubber is added to the solvent, and stirred at normal temperature until the nitrile rubber is completely dissolved to obtain a nitrile rubber solution; lithium salt is added to the above nitrile rubber solution, Continue to stir until the lithium salt is completely dissolved to obtain a primary mixed solution; add octa(polyethylene glycol)-cage polysilsesquioxane dropwise to the above primary mixed solution, and stir until dissolved to obtain a secondary mixed solution. The solvent of the secondary mixed solution was volatilized in a vacuum oven to a constant weight to obtain...

Embodiment 1

[0045] The solid polymer electrolyte described in the present embodiment comprises the following components by weight: 0.5g of nitrile rubber, 0.05g of octa(polyethylene glycol)-cage polysilsesquioxane, 0.25g of lithium perchlorate . Wherein, the mass fraction of acrylonitrile in the nitrile rubber is 25%. Provide 10ml of solvent tetrahydrofuran for dissolving nitrile rubber, add nitrile rubber in the tetrahydrofuran solvent, stir until the nitrile rubber is completely dissolved at normal temperature, and obtain the nitrile rubber solution; add lithium perchlorate in the above-mentioned nitrile rubber solution, Continue to stir until the lithium perchlorate is completely dissolved to obtain a primary mixed solution; add octa(polyethylene glycol)-cage polysilsesquioxane dropwise to the above primary mixed solution, and stir until dissolved to obtain a secondary mixed solution. The above-mentioned secondary mixed solution is poured into a polytetrafluoroethylene mold, and the p...

Embodiment 2

[0051] The solid polymer electrolyte described in the present embodiment comprises the following components by weight: 0.5g of nitrile rubber, 0.1g of octa(polyethylene glycol)-cage polysilsesquioxane, 0.25g of lithium perchlorate . Wherein, the mass fraction of acrylonitrile in the nitrile rubber is 30%. Provide 10ml of solvent tetrahydrofuran for dissolving nitrile rubber, add nitrile rubber in the tetrahydrofuran solvent, stir until the nitrile rubber is completely dissolved at normal temperature, and obtain the nitrile rubber solution; add lithium perchlorate in the above-mentioned nitrile rubber solution, Continue to stir until the lithium perchlorate is completely dissolved to obtain a primary mixed solution; add octa(polyethylene glycol)-cage polysilsesquioxane dropwise to the above primary mixed solution and stir until dissolved to obtain a secondary mixed solution. The above-mentioned secondary mixed solution is poured into a polytetrafluoroethylene mold, and the pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com