Nano-rod porous carbon-sulfur composite cathode material, preparation method thereof and lithium-sulfur battery

A composite positive electrode material and porous carbon technology, applied in the field of lithium-ion batteries, can solve the problems that the polysulfide shuttle effect cannot be well resolved, polysulfides cannot be bound in the positive electrode area, and the conductivity of the sulfur electrode is poor. Suppression of the shuttle effect, improvement of electrochemical performance, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

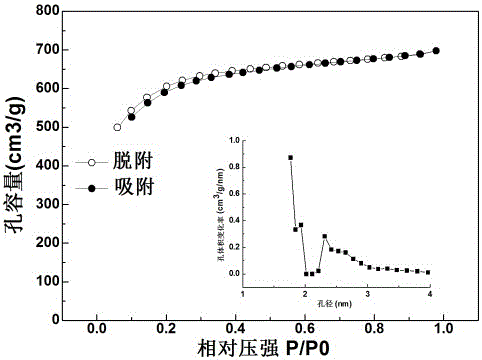

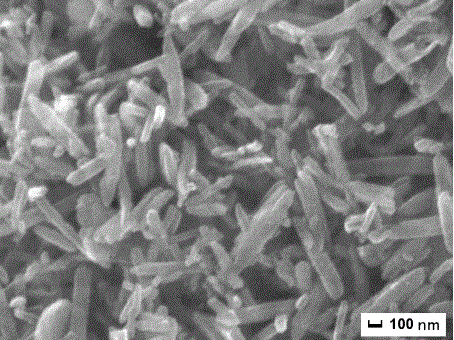

[0033] A nanorod porous carbon-sulfur composite positive electrode material of the present invention, the positive electrode material is a composite material of nanorod porous carbon and sublimated sulfur, the sublimated sulfur is located in the nanorod porous carbon channel, and the mass ratio of sublimated sulfur to nanorod porous carbon is The ratio is 2:1, the pore diameter of nanorod porous carbon is 1nm~3nm, the length is 800nm, and the diameter is 50nm; the specific surface area of nanorod porous carbon is 1800m 2 / g, the pore volume is 2.5 cm 3 / g.

[0034] The preparation method of the nanorod porous carbon-sulfur composite cathode material of this embodiment comprises the following steps:

[0035] (1) Dissolve 0.594g of zinc nitrate hexahydrate in 20ml of deionized water to make an aqueous solution, add 0.562g of 4,4'-biphenyldicarboxylic acid disodium salt (dilute 4,4'-biphenyldicarboxylic acid and NaOH according to molar A neutralization reaction occurs in an a...

Embodiment 2

[0043] A nanorod porous carbon-sulfur composite positive electrode material of the present invention, the positive electrode material is a composite material of nanorod porous carbon and precipitated sulfur, the precipitated sulfur is located in the pores of the nanorod porous carbon, and the mass ratio of the precipitated sulfur to the nanorod porous carbon is 3:1, the pore diameter of nanorod porous carbon is 1nm~3nm, the length is 500nm, and the diameter is 30nm; the specific surface area of nanorod porous carbon is 2000 m 2 / g, the pore volume is 2.8cm 3 / g.

[0044] The preparation method of the nanorod porous carbon-sulfur composite cathode material of this embodiment comprises the following steps:

[0045] (1) Dissolve 0.594g of zinc nitrate hexahydrate in 30ml of deionized water to make an aqueous solution, dissolve 0.562g of 4,4'-biphenyl dicarboxylic acid disodium salt in 30ml of deionized water to make an aqueous solution, and then mix the two The aqueous soluti...

Embodiment 3

[0051] A nanorod porous carbon-sulfur composite positive electrode material of the present invention, the positive electrode material is a composite material of nanorod porous carbon and sublimated sulfur, the sublimated sulfur is located in the nanorod porous carbon channel, and the mass ratio of sublimated sulfur to nanorod porous carbon is 4:1, the pore diameter of nanorod porous carbon is 1nm~3nm, the length is 800nm, and the diameter is 40nm; the specific surface area of nanorod porous carbon is 1400 m 2 / g, the pore volume is 2.3cm 3 / g.

[0052] The preparation method of the nanorod porous carbon-sulfur composite cathode material of this embodiment comprises the following steps:

[0053] (1) Dissolve 1.188g of zinc nitrate hexahydrate in 15ml of deionized water to make an aqueous solution, dissolve 1.144g of 4,4'-biphenyl dicarboxylic acid disodium salt in 15ml of deionized water to make an aqueous solution, and then mix the two The aqueous solution was mixed and st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com