A Method of Improving the Breakdown Resistance of Ferroelectric Thin Films

A ferroelectric thin film, anti-breakdown technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, etc., can solve the problems such as the interface between the thin film and the electrode is not very tight, the leakage current of the ferroelectric thin film increases, and achieves Improve the anti-breakdown ability, increase the contact area, and reduce the effect of leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

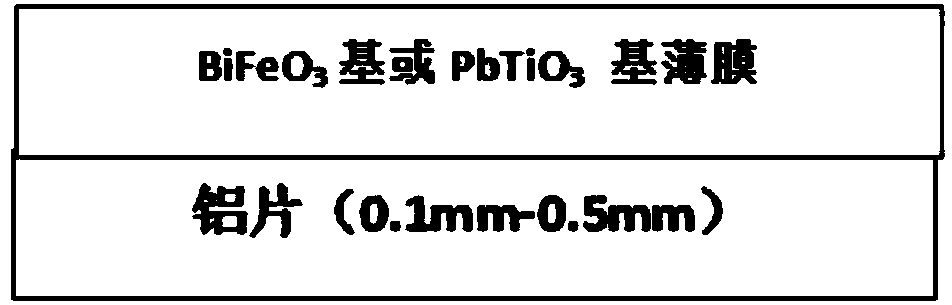

[0042] Preparation of pure BiFeO on an aluminum sheet with a length and width of 2×2 cm and a thickness of 0.3 mm 3 thin film, BiFeO 3 The film preparation process is as follows:

[0043] 1. Pretreatment of aluminum sheets: tear off the surface protective film of 2×2cm aluminum sheets with a thickness of 0.3mm, then burn them in a nitrogen atmosphere at 300°C for 10 minutes in a rapid annealing furnace, and then cool them to room temperature under nitrogen conditions.

[0044] 2. BiFeO 3 Film preparation:

[0045] 2.1 Weigh bismuth nitrate and iron nitrate with a molar ratio of 1.1:1, respectively, and use 40 ml of ethylene glycol and acetic acid as solvents to prepare a precursor solution with a concentration of 0.5 mol / L;

[0046] 2.2 Preparation of BiFeO by spin coating-layer annealing method 3 film. The precursor solution was deposited on the pretreated aluminum sheet by the spin coating method, and then the material was placed on a hot plate to dry, and the dried fil...

Embodiment 2

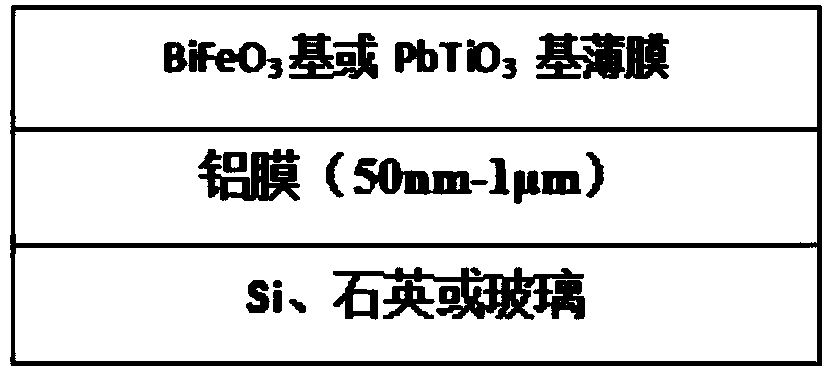

[0049] Preparation of pure BiFeO on Al / Si electrode with Al film thickness of 1 μm 3 thin film, BiFeO 3 The film preparation process is as follows:

[0050] 1. Electrode pretreatment: An aluminum film with a thickness of 1 micron is plated on the Si electrode by evaporation to obtain an Al / Si electrode. An Al / Si electrode with an aluminum film thickness of 1 micron was pre-fired in a rapid annealing furnace at 400° C. for 3 minutes in a nitrogen atmosphere, and then cooled to room temperature in a nitrogen atmosphere.

[0051] 2. BiFeO 3 Film preparation:

[0052] 2.1 Weigh bismuth nitrate and iron nitrate with a molar ratio of 1.1:1 respectively, and use 40 ml ethylene glycol and acetic acid as solvents to prepare a precursor solution with a concentration of 1 mol / L;

[0053] 2.2 Preparation of BiFeO by spin coating-layer annealing method 3 film. The precursor solution was deposited on the pretreated Al / Si electrode by the spin coating method, and then the material was ...

Embodiment 3

[0056] Preparation of Bi on an aluminum sheet with a length and width of 2×2 cm and a thickness of 0.3 mm 0.95 La 0.05 FeO 3 Film, Bi 0.95 La 0.05 FeO 3 The film preparation process is as follows:

[0057] 1. Pretreatment of aluminum sheets: tear off the surface protective film of 2×2cm aluminum sheets with a thickness of 0.3mm, and then burn in a rapid annealing furnace at 400°C for 3 minutes under a nitrogen atmosphere, and then cool to room temperature under nitrogen.

[0058] 2. Bi 0.95 La 0.05 FeO 3 Film preparation:

[0059] 2.1 Weigh bismuth nitrate, iron nitrate and lanthanum nitrate with a molar ratio of 1.1:1:0.05 respectively, and use 40 ml of ethylene glycol and acetic acid as solvents to prepare a precursor solution with a concentration of 1 mol / L;

[0060] 2.2 The precursor solution was deposited on the pretreated aluminum sheet by the spin coating method, and then the material was placed on a hot plate to dry, and the dried film was placed in a rapid an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com