Preparation method for fabric tension sensor

A sensor and fabric technology, applied in the field of functional textiles and smart textiles, to achieve stable performance, wide application prospects, and small dielectric constant.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

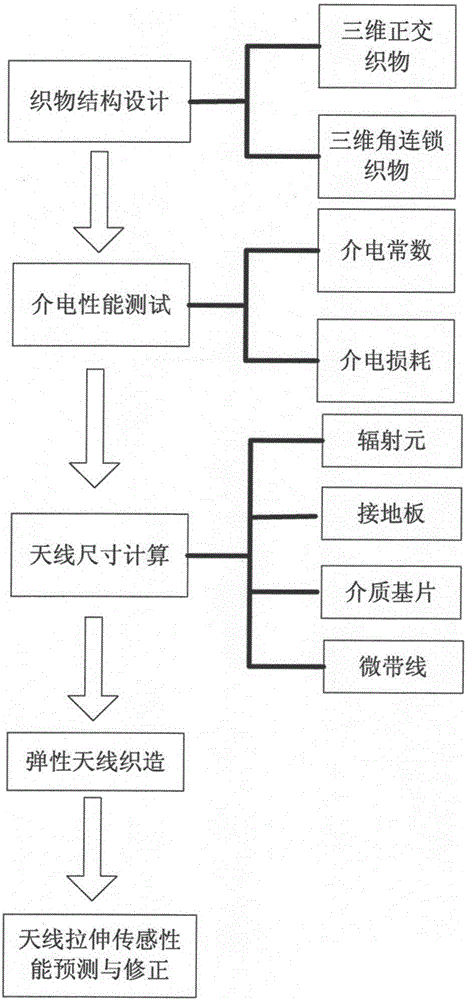

[0037] combine figure 1 , the preparation of three-dimensional orthogonal structure tensile sensing antenna fabric, the specific method is as follows:

[0038] (1) Select the silver-plated elastic polyester yarn as the conductive yarn, carry out chemical silver plating under the pre-stretched 50% situation of the elastic polyester yarn (U.S. DuPont Company) with a fineness of 400dtex, and make the yarn retract after the silver plating ends to obtain Stretchy conductive polyester yarn.

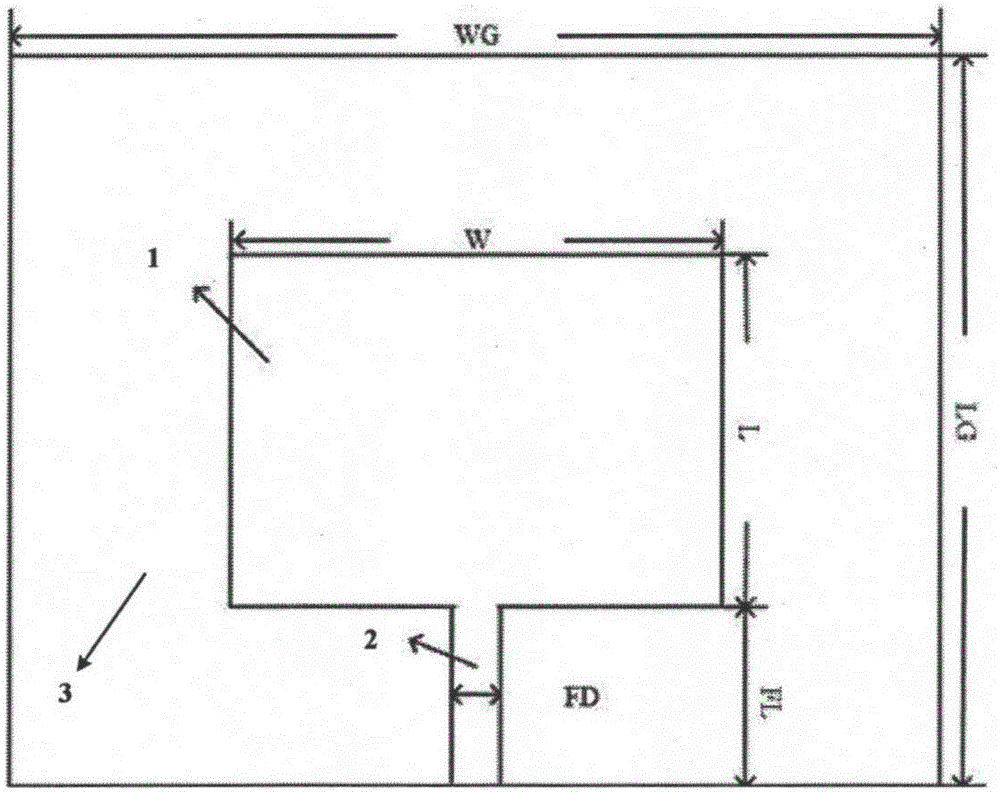

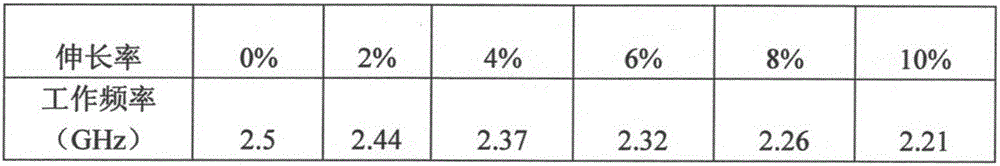

[0039] (2) The operating frequency of the designed antenna is 2.5 GHz, the thickness of the prepared three-dimensional fabric is 1.5 mm, and its dielectric constant r=2, according to the antenna design theory (see Chapter 6 of "Antenna Theory and Technology", edited by Zhong Shunshi) The size parameters of the single radiating element microstrip antenna are calculated; for example figure 2 shown. figure 2 Among them, 1 is the radiating element, 2 is the feeding line, and 3 is the substrate...

Embodiment 2

[0045] The preparation of stretch sensing antenna fabric based on carbon tube coated yarn, the specific method is as follows:

[0046] (1) Multi-wall carbon nanotube coated spandex yarn (Jiangsu Qiaoxin Fiber Co., Ltd.) with a fineness of 560 dtex was selected as the elastic conductive yarn. When the spandex yarn is pre-stretched by 50%, it is immersed in the aqueous dispersion of multi-walled carbon nanotubes (Chengdu Organic Chemistry Co., Ltd., Chinese Academy of Sciences), and the pre-stretching force is released after the water is dried and volatilized to make the yarn retract Elastically stretchable conductive yarns are obtained.

[0047](2) The operating frequency of the antenna is designed to be 3GHz, the thickness of the prepared three-dimensional fabric is 1.3mm, and its dielectric constant r=2. According to the antenna design theory, the size parameters of the microstrip antenna with single radiating element are calculated, such as figure 2 shown. figure 2 Among...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com