Concrete foundation prefabricated slab and construction method thereof

A concrete foundation and construction method technology, applied in the direction of basic structure engineering, construction, etc., can solve the problems of high cost, long construction period, large amount of brick tire formwork masonry, etc., and achieve the effect of preventing cracking and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

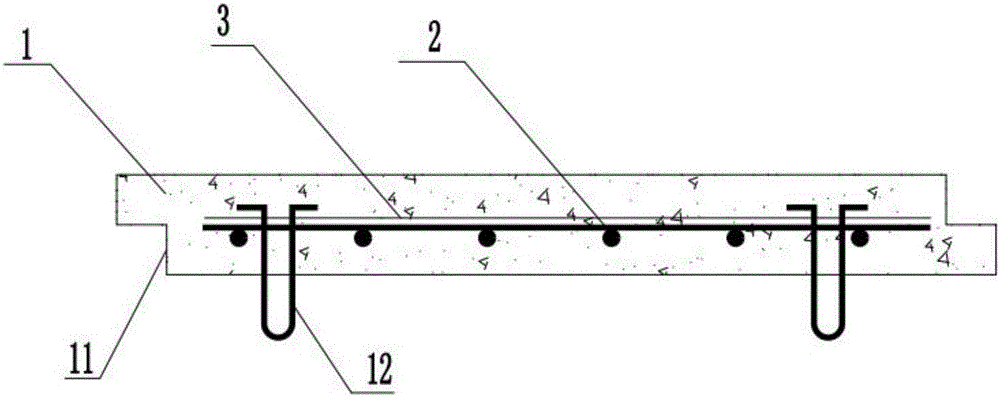

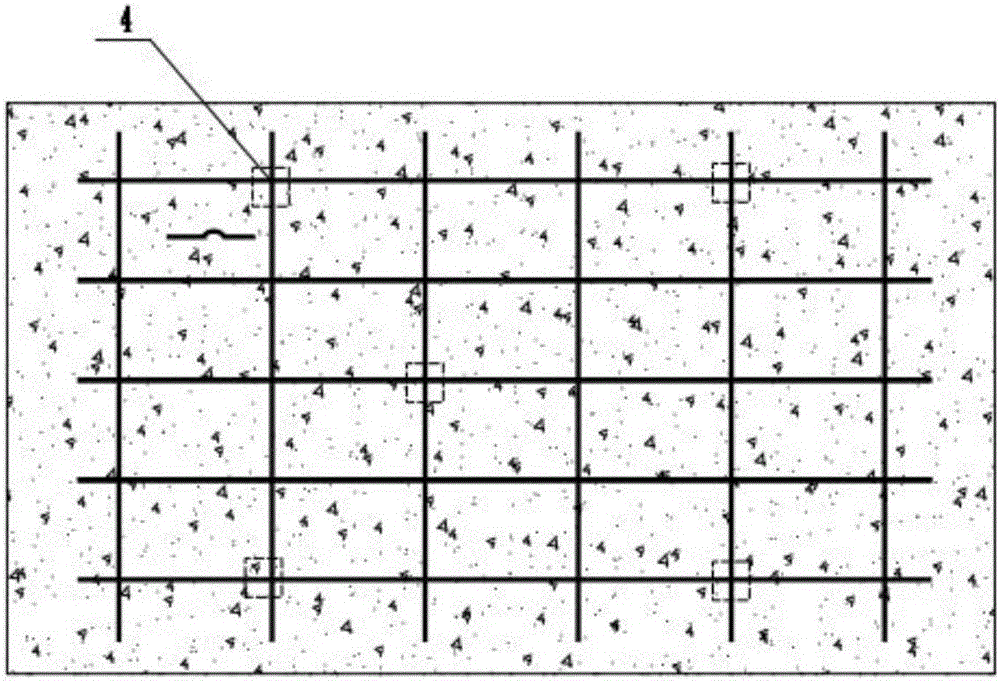

[0019] like figure 1 and figure 2 As shown, the present invention provides a concrete foundation prefabricated slab, comprising a base plate 1, an anti-cracking net 3, a plurality of steel bars 2 and a plurality of pads 4, and the concrete foundation prefabricated slab can be made in advance according to the size of the building foundation, shortening the The construction time of traditional masonry brick tire formwork can greatly shorten the construction period.

[0020] The steel bar 2, the anti-cracking net 3 and the spacer 4 are all arranged inside the base plate 1, and the side wall of the base plate 1 is provided with a lifting hook 12, through which the lifting hook 12 can not only facilitate the lifting operation of the prefabricated concrete foundation slab, but also One end of the reinforcing iron wire is fixed on the lifting hook 12, and the side wall of the concrete foundation prefabricated plate is fixed on the soil body stake to ensure the safety of constructio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com