Wood-plastic ceramic composite material and preparation method thereof

A ceramic composite material and wood-plastic technology, which is applied in the field of composite materials, can solve the problems of low qualified rate of special ceramics production, ineffective utilization, difficult plastic degradation, etc., and achieve the effect of wide supply of raw materials, low cost and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

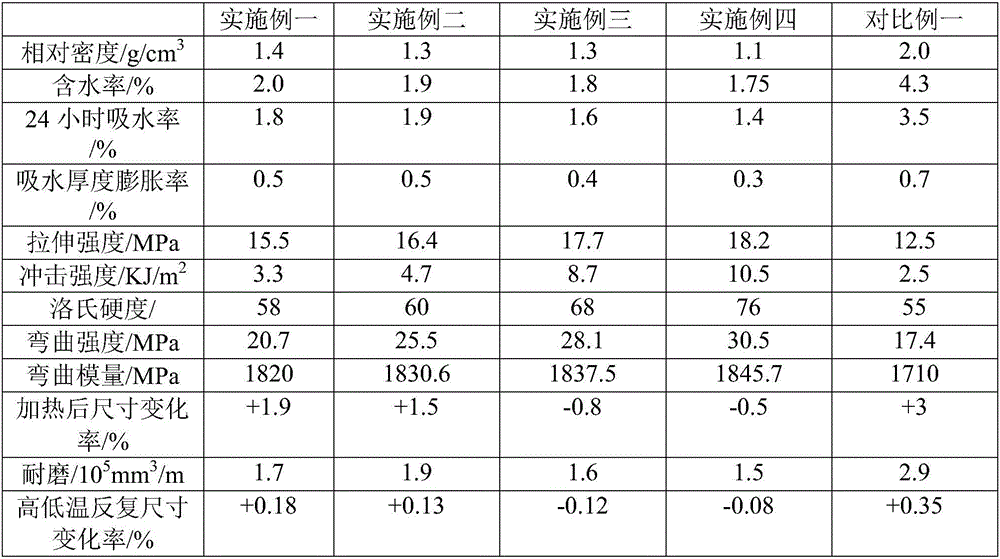

Examples

Embodiment 1

[0029] The composition of the wood-plastic ceramic composite material is as follows in parts by mass:

[0031] Waste polyethylene plastic (irregular sheet): 20 parts

[0032] Waste silicon nitride ceramic powder: 10 parts

[0033] Aluminum hydroxide: 0.1 parts

[0034] Maleic anhydride grafted polyethylene: 1 part

[0035] Polyethylene wax: 0.5 parts

[0036] Dioctyl phthalate: 1 part

[0037] Tris(2.4-di-tert-butylphenyl)phosphite: 0.1 parts

[0038] Carbon black: 0.1 parts

[0039] Prepare the above-mentioned wood-plastic-ceramic composite material according to the following preparation method:

[0040] (1) Weigh the crop straw according to the mass parts described in Example 1, dry the crop straw, and break it into 40-80 mesh fiber powder;

[0041] (2) According to the mass parts described in Example 1, waste and old polyethylene plastics are weighed, and after the waste and old polyethylene plastics are sorted, crushed, cleaned and dri...

Embodiment 2

[0048] 木塑陶瓷复合材料按质量份计成分如下:

[0049] 稻壳:50份

[0050] 废旧聚丙烯塑料(不规则片状):30份

[0051] 废旧碳化硅陶瓷粉体:15份

[0052] 氢氧化铝:1.5份

[0053] 马来酸酐接枝聚乙烯:3份

[0054] 聚乙烯蜡:1.5份

[0055] 邻苯二甲酸二辛酯:2份

[0056] 三(2.4-二叔丁基苯基)亚磷酸酯:0.5份

[0057] 炭黑:0.2份

[0058] 按照以下制备方法制备上述的木塑陶瓷复合材料:

[0059] (1)按照实施例二所述的质量份称取稻壳,将稻壳干燥后,破碎成40-80目的纤维粉体;

[0060] (2)按照实施例二所述的质量份称取废旧聚丙烯塑料,将废旧聚丙烯塑料进行分拣、破碎、清洗、干燥处理后,进行混合均化备用;

[0061] (3)将回收的废旧碳化硅陶瓷进行破碎、清洗后,研磨成400-1000目的碳化硅粉,通过铝酸酯偶联剂F-1对碳化硅粉进行接枝改性处理,得到废旧碳化硅陶瓷粉体;

[0062] 所述废旧碳化硅陶瓷粉体的制备方法如下:

[0063] 称取0.5g碳化硅粉,加入20mL甲苯,常温用300W的超声波清洗器超声分散30min,得到均匀悬浮液,再向其中加入铝酸酯偶联剂F-1,铝酸酯偶联剂F-1的浓度为1.0%,继续超声3~4min,转移到烧瓶中,在90℃的温度中搅拌反应6h,反应结束后以12000r / min的速度常温离心分离,即得废旧碳化硅陶瓷粉体。

[0064] (4)按照实施例二所述的质量份称取步骤(3)中的废旧碳化硅粉体,按照实施例二所述的质量份称取氢氧化铝、马来酸酐接枝聚乙烯、聚乙烯蜡、邻苯二甲酸二辛酯、三(2.4-二叔丁基苯基)亚磷酸酯、炭黑,将步骤(1)中的纤维粉体、步骤(2)处理后的废旧聚丙烯塑料、步骤(3)中的废旧碳化硅粉体与氢氧化铝、马来酸酐接枝聚乙烯、聚乙烯蜡、邻苯二甲酸二辛酯、三(2.4-二叔丁基苯基)亚磷酸酯、炭黑进行充分混匀,得到混合料;

[0065] (5)通过双螺杆挤出机,在加工温度150-250℃,转速150-200转 / 分钟下,对混合料进行混炼挤出并风冷造粒,制得木塑陶瓷复合材料。

Embodiment 3

[0067] 木塑陶瓷复合材料按质量份计成分如下:

[0068] 木屑和花生壳的组合物:50份

[0069] 废旧聚苯乙烯塑料(不规则片状):30份

[0070] 废旧二氧化硅陶瓷粉体:15份

[0071] 氢氧化镁:2份

[0072] 马来酸酐接枝聚乙烯:4份

[0073] 聚乙烯蜡:2份

[0074] 邻苯二甲酸二丁酯:3份

[0075] 抗氧剂1010:0.5份

[0076] 铁红和钛青蓝的组合物:0.2份

[0077] 按照以下制备方法制备上述的木塑陶瓷复合材料:

[0078] (1)按照实施例三所述的质量份称取木屑和花生壳的组合物,将木屑和花生壳的组合物干燥后,破碎成40-80目的纤维粉体;

[0079] (2)按照实施例三所述的质量份称取废旧聚苯乙烯塑料,将废旧聚苯乙烯塑料进行分拣、破碎、清洗、干燥处理后,进行混合均化备用;

[0080] (3)将回收的废旧二氧化硅陶瓷进行破碎、清洗后,研磨成400-1000目的二氧化硅粉,通过钛酸酯偶联剂201对二氧化硅粉进行接枝改性处理,得到废旧二氧化硅粉体;

[0081] 所述废旧二氧化硅粉体的制备方法如下:

[0082] 称取1.5g二氧化硅粉,加入20mL甲苯,常温用300W的超声波清洗器超声分散30min,得到均匀悬浮液,再向其中加入钛酸酯偶联剂201,钛酸酯偶联剂201的浓度为1.5%,继续超声3~4min,转移到烧瓶中,在90℃的温度中搅拌反应6h,反应结束后以12000r / min的速度常温离心分离,即得废旧二氧化硅粉体。

[0083] (4)按照实施例三所述的质量份称取步骤(3)中的废旧二氧化硅粉体,按照实施例三所述的质量份称取氢氧化镁、马来酸酐接枝聚乙烯、聚乙烯蜡、邻苯二甲酸二丁酯、抗氧剂1010、铁红和钛青蓝的组合物,将步骤(1)中的纤维粉体、步骤(2)处理后的废旧聚苯乙烯塑料、步骤(3)中的废旧二氧化硅粉体与氢氧化镁、马来酸酐接枝聚乙烯、聚乙烯蜡、邻苯二甲酸二丁酯、抗氧剂1010、铁红和钛青蓝的组合物进行充分混匀,得到混合料;

[0084] (5)通过双螺杆挤出机,在150-250℃,转速150-200转 / 分钟下,对混合料进行混炼挤出并风冷造粒,制得木塑陶瓷复合材料。

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com