Polyvinyl alcohol film with high swelling degree and preparation method thereof

A polyvinyl alcohol film and polyvinyl alcohol-based technology, which is applied in the field of polymer film preparation, can solve the problems of small swelling degree, influence on dyeing effect, low elongation at break, etc., and achieve high swelling degree, simple process and high polarized light. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The present invention also provides a preparation method of the above-mentioned polyvinyl alcohol film with a high degree of swelling, and the preparation method includes the following steps.

[0027] Step A:

[0028] Prepare a film-making stock solution containing polyvinyl alcohol-based polymers, polypropylene glycol, polyols and solvents. Among them, preferably in the film-making stock solution, the mass fraction of the polyvinyl alcohol-based polymer is controlled to be 5-30%, the mass fraction of polypropylene glycol is 0.1-3% of the mass fraction of the polyvinyl alcohol-based polymer, and the mass fraction of the polyol is The fraction is 0.5-5% of the mass fraction of the polyvinyl alcohol-based polymer and the balance is solvent, wherein the sum of the contents of each component is 100%.

[0029] During specific preparation, the solvent is added into a container containing polyvinyl alcohol-based polymers, polypropylene glycol and polyols, and stirred for 5-6 ...

Embodiment 1

[0043] Weigh 40g of polyvinyl alcohol, 0.4g of polypropylene glycol and 0.8g of pentaerythritol into a 500ml three-necked flask, fix the three-necked flask on an iron stand, and install a stirring device and a reflux device.

[0044] Measure 360ml of deionized water as a solvent and add it to the flask, heat it in a water bath to 95°C and stir for 6 hours to completely dissolve the polyvinyl alcohol to obtain a film-making stock solution, in which the degree of polymerization of polyvinyl alcohol is 5000 and the degree of alcoholysis is 99.5% , The molecular weight of polypropylene glycol is 3000.

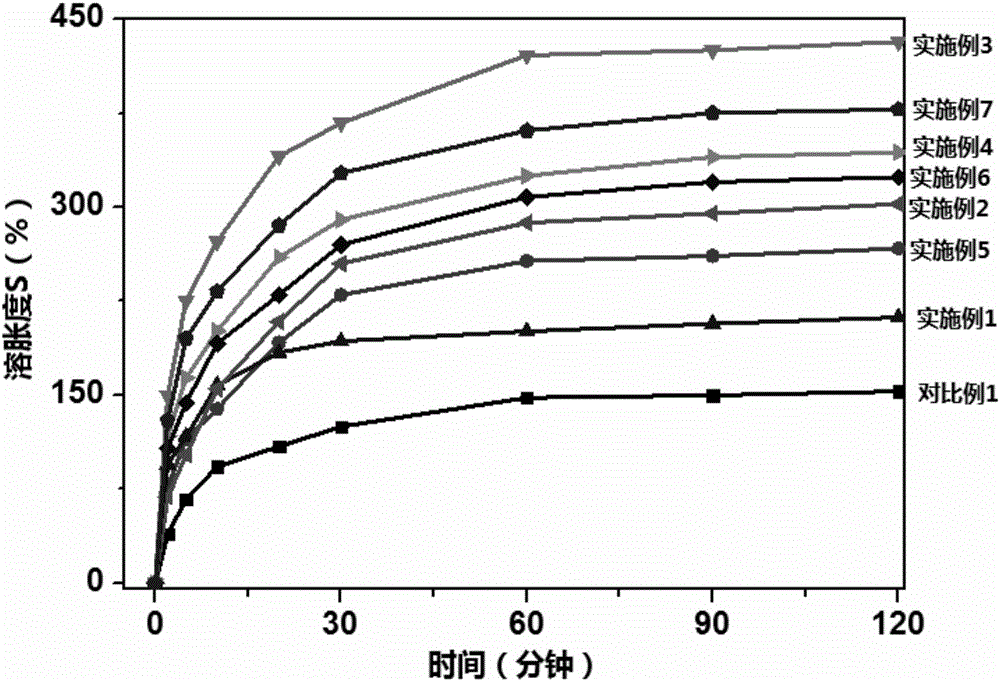

[0045] The film-making stock solution was poured into a petri dish, cast into a film and dried in an incubator. The temperature of the incubator was controlled at 60° C. and the drying time was 8 hours to obtain a polyvinyl alcohol film sample. The variation curve of polyvinyl alcohol film swelling degree with time in the present embodiment is as follows figure 1 As shown, in this...

Embodiment 2

[0048] Weigh 40g of polyvinyl alcohol, 0.4g of polypropylene glycol and 1.2g of pentaerythritol into a 500ml three-necked flask, fix the three-necked flask on an iron stand, and install a stirring device and a reflux device.

[0049] Measure 360ml of deionized water as a solvent and add it to the flask, heat it in a water bath to 95°C and stir for 6 hours to completely dissolve the polyvinyl alcohol to obtain a film-making stock solution, in which the degree of polymerization of polyvinyl alcohol is 5000 and the degree of alcoholysis is 99.5% , The molecular weight of polypropylene glycol is 3000.

[0050] The film-making stock solution was poured into a petri dish, cast into a film and dried in an incubator. The temperature of the incubator was controlled at 60° C. and the drying time was 12 hours to obtain a polyvinyl alcohol film sample. The variation curve of polyvinyl alcohol film swelling degree with time in the present embodiment is as follows figure 1 As shown, in thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| alcoholysis degree | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com