Furan resin synthesized with modifying lignin and preparing method of furan resin

A furan resin and lignin technology, which is applied in casting molding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of complex products, unfavorable industrial production, harsh reaction conditions, etc., and achieve simple modification methods and high modification effects Good, stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

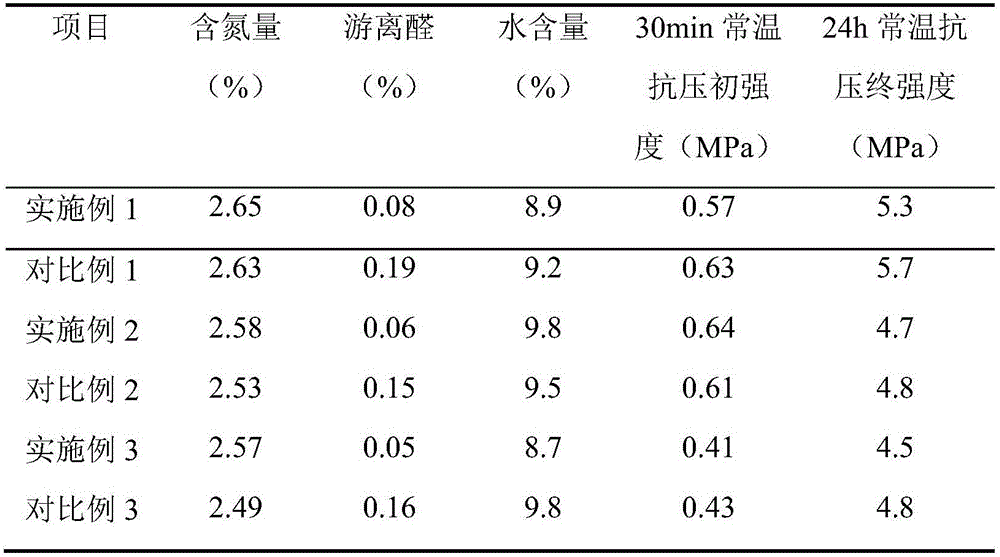

Examples

Embodiment 1

[0033] Reaction steps: Weigh 30 kg of the above-mentioned high-purity lignin, 15 kg of maleic anhydride and 3 kg of xylitol respectively, place them in a high-mix mixer, and stir at 100°C for 15 minutes to fully mix and react to obtain modified lignin.

[0034] Add 47.8kg of formaldehyde (concentration 37%) and 16kg of urea to the reaction kettle, start stirring, after the urea dissolves, adjust the pH range of the solution with sodium hydroxide between 8.3-8.7, heat up to 85±2°C and react for 1 hour; Dehydrate 28kg under vacuum conditions, add 105kg of furfuryl alcohol in one step and 48kg of modified lignin and react for 1 hour at 85±2°C; add 69kg of furfuryl alcohol in two steps, adjust the material system pH4. Keep warm at 105°C for 2 hours; add 3.5kg of two-step urea, adjust the pH value of the solution between 8.0-8.5 with sodium hydroxide, stop the reaction after reacting at 80±2°C for 0.5 hours, and adjust the pH value of the system to 6.5-7.5; add 90kg of three-step fu...

Embodiment 2

[0036] Reaction steps: Weigh 25kg of the above-mentioned high-purity lignin, 13kg of maleic anhydride and 2kg of xylitol respectively, place them in a high-mix mixer, and stir at 90°C for 10 minutes to fully mix and react to prepare modified lignin.

[0037] Add 42kg of formaldehyde (concentration 37%) and 13kg of urea to the reaction kettle, start stirring, after the urea dissolves, adjust the pH range of the solution with potassium hydroxide between 8.5-9.0, heat up to 90±2°C and react for 1 hour; Dehydrate 25kg under the same conditions, add 90kg of furfuryl alcohol in one step and 40kg of modified lignin at 90±2℃-react for 1.5 hours; add 55kg of furfuryl alcohol in second step, adjust the pH of the material system to 4.0-4.2 with 10% hydrochloric acid, and the reaction temperature is 100±2 Keep warm at ℃ for 3 hours; add 3kg of two-step urea, potassium hydroxide to adjust the pH value of the solution between 8.1-8.4, stop the reaction after reacting at 85±2°C for 0.5 hours,...

Embodiment 3

[0039] Reaction steps: Weigh 68 kg of the above-mentioned high-purity lignin, 24 kg of maleic anhydride and 8 kg of xylitol, place them in a high-mix mixer, and stir at 105° C. for 20 minutes to fully mix and react to prepare modified lignin.

[0040] Add 70kg of formaldehyde (concentration 37%) and 22kg of urea into the reaction kettle, start stirring, after the urea is dissolved, adjust the pH range of the solution to 8.0-8.5 with hexamethylenetetramine, raise the temperature to 80-85°C and react for 1 hour ;Dehydrate 42kg under vacuum conditions, add 135kg of furfuryl alcohol in one step and 100kg of modified lignin and react for 1 hour at 80-85°C; add 35kg of furfuryl alcohol in two steps, adjust the material system pH3. Incubate at ±2°C for 1.5 hours; add 5kg of two-step urea, adjust the pH value of the solution between 8.1-8.4 with sodium hydroxide, stop the reaction after reacting at 85±2°C for 0.5 hours, adjust the pH value of the system to 6.5-7.5; add 175kg of three-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com