Waterproof and anti-permeability phase-change-energy-storage gypsum block and preparing method thereof

A gypsum block and phase change energy storage technology, which is applied to chemical instruments and methods, ceramic products, and other household appliances, can solve problems such as poor compatibility of building materials, leakage of phase change materials, and short service life, so as to prevent Phase change material loss, simple manufacturing process, and reduced consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

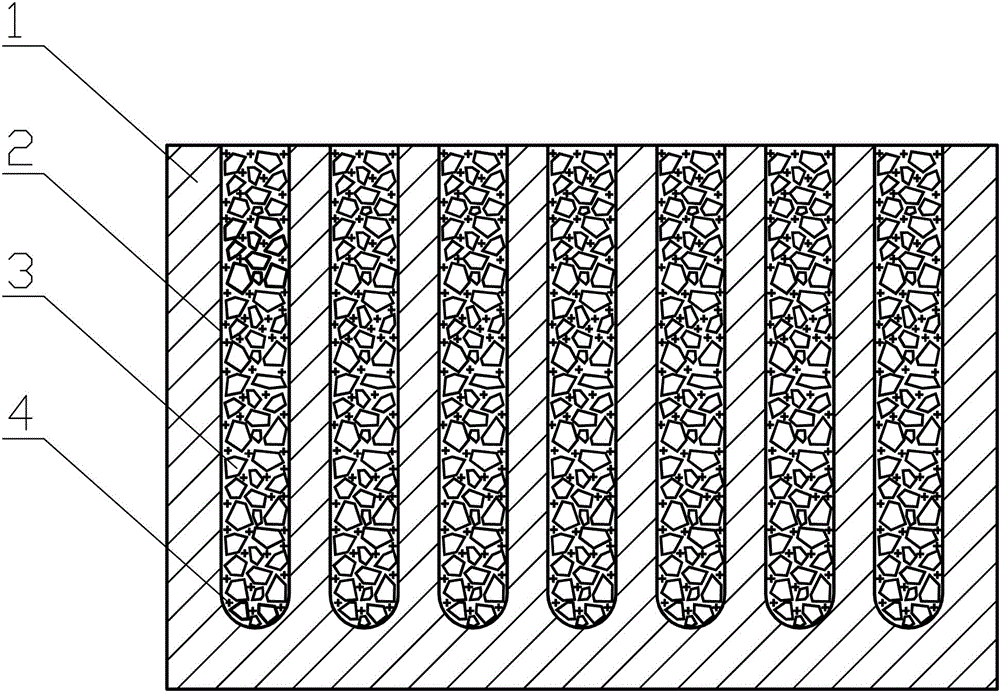

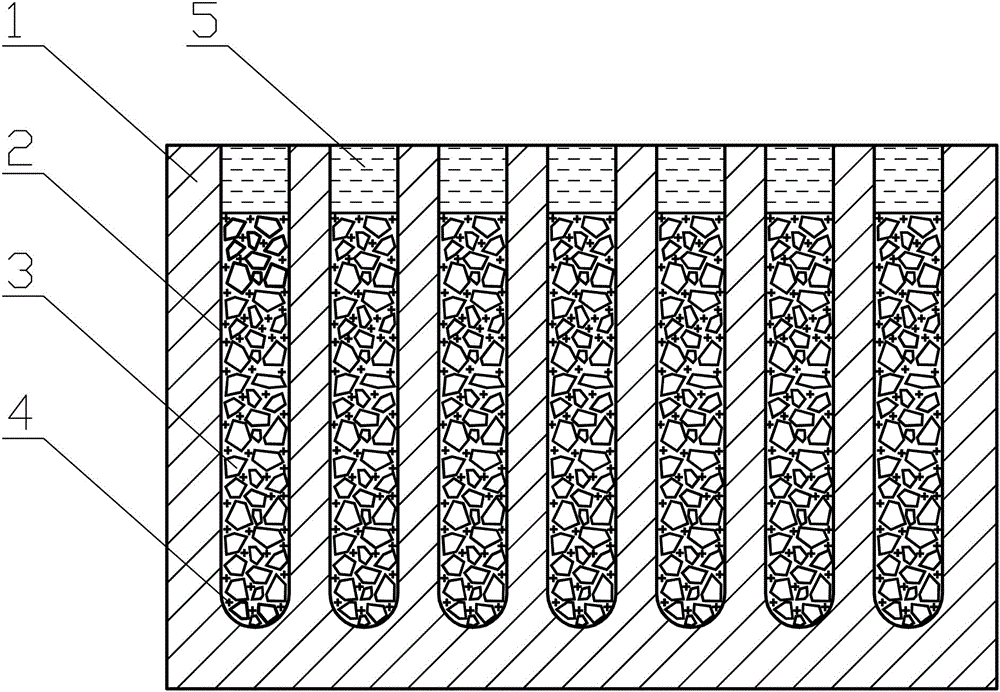

[0032] Step 1: By weight, 73 parts of desulfurized building gypsum, 20 parts of active admixture (specific surface area 490m 2 / kg), 7 parts of 32.5 composite Portland cement to make mixed powder; 0.7 parts of sodium methyl siliconate, 0.4 parts of waste mycelium protein retarder, 0.4 parts of polycarboxylate superplasticizer and 48 parts of water to make a mixed solution; mix the mixed powder and the mixed solution evenly to make a slurry, inject the slurry into a mold, and make a gypsum block body with blind holes; the number of blind holes is 11 , with a diameter of 40mm and a depth of 420mm;

[0033] Step 2: Add 9 parts of expanded vermiculite with a particle size of 6 to 12 mm into the blind hole of the gypsum block body obtained in Step 1;

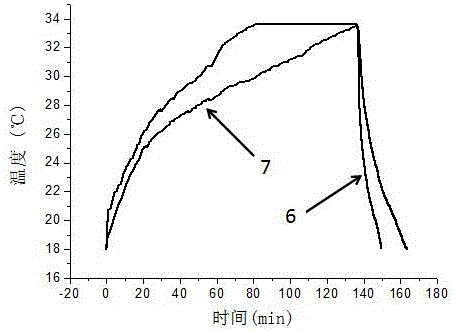

[0034] Step 3: Heat up capric acid and 30% stearic acid with a weight ratio of 70% to melt, mix evenly, and pour 20 parts of the prepared phase change energy storage material (its phase change temperature is 22°C) into gypsum blocks...

Embodiment 2

[0038] Step 1: By weight, 65 parts of desulfurized building gypsum, 25 parts of active admixture (specific surface area 457m 2 / kg), 10 parts of 32.5# slag portland cement to make mixed powder; 0.5 parts of VAE emulsion, 0.2 parts of sodium polyphosphate retarder, 0.3 parts of polycarboxylate superplasticizer and 50 parts water to make a mixed solution; mix the mixed powder and the mixed solution evenly to make a slurry, inject the slurry into the mold, and make a gypsum block body with blind holes; the number of blind holes is 9, and the diameter is 50mm, the depth is 400mm;

[0039]Step 2: Add 8.5 parts of waste autoclaved aerated concrete particles with a particle size of 6 to 12 mm into the blind hole of the gypsum block body obtained in Step 1;

[0040] Step 3: Heat up 50% capric acid and 50% stearic acid by weight to melt, mix evenly, pour 19 parts of the prepared phase-change energy storage material (its phase-change temperature is 35°C) into gypsum masonry In the bli...

Embodiment 3

[0046] Step 1: By weight, 80 parts of desulfurized building gypsum, 15 parts of active admixture (specific surface area 542m 2 / kg), 5 parts of 42.5# ordinary Portland cement to make mixed powder; 1 part of potassium methyl silicate, 0.5 parts of sodium citrate, 0.5 parts of naphthalene-based water reducer and 45 parts of water Make a mixed solution; mix the mixed powder and the mixed solution evenly to make a slurry, inject the slurry into a mold, and make a gypsum block body with blind holes; the number of blind holes is 7, and the diameter is 70mm. The depth is 380mm;

[0047] Step 2: Add 8 parts of light shale ceramsite with a particle size of 6 to 12 mm into the blind hole of the gypsum block body obtained in Step 1;

[0048] Step 3: heat up capric acid with a weight ratio of 95% and stearic acid with a weight ratio of 5% to melt, mix well, and pour 19 parts of the prepared phase-change energy storage material (its phase-change temperature is 28°C) into gypsum masonry I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com