High-temperature-condensed-water oil removing technology

A high-temperature condensate water and process technology, applied in water/sewage treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of poor water impact resistance of filter membranes, small water production, and secondary pollution and other problems, to achieve the effect of low water pretreatment requirements, long membrane service life and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

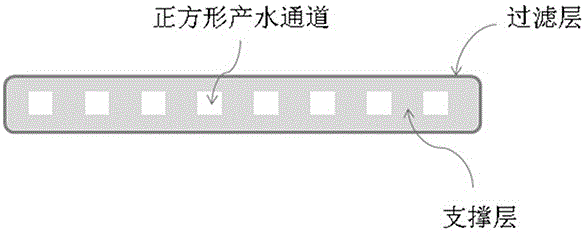

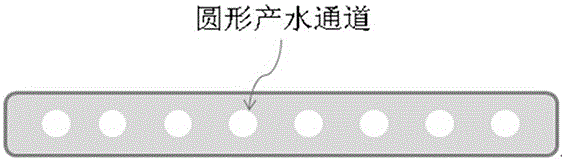

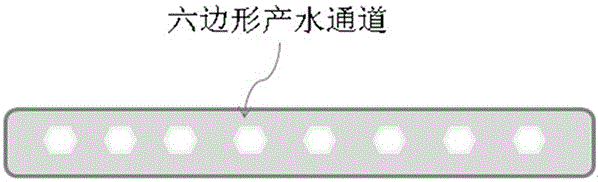

[0099] The inorganic carbon membrane includes a support layer and a separation layer;

[0100] The thickness of the separation layer is 0.05 microns;

[0101] The filter pore size of the separation layer is 20nm;

[0102] The support layer is composed of parts by weight:

[0103] Aggregate: 40 parts coal powder, 10 parts phenolic resin, 20 parts white carbon black, 5 parts bentonite, 8 parts burnt kaolin;

[0104] Pore-forming agent: 0.5 parts of purple wood knot, 0.3 parts of serpentine powder;

[0105] Additives: 1 part of copper nitrate, 2 parts of dimethyl disilane modified silica;

[0106] Dispersant: 0.8 parts of lecithin.

[0107] The preparation steps of the separation layer are:

[0108] Ingredients: 15 parts of white carbon black, 25 parts of coal powder, 0.5 parts of purple wood knots are prepared according to the weight ratio;

[0109] Coating solution solvent preparation: weigh and mix glycerol, ethylene glycol and 1,4-butanediol in a volume ratio of 10:8:30;

[0110] Separation ...

Embodiment 2

[0114] The inorganic carbon membrane includes a support layer and a separation layer;

[0115] The thickness of the separation layer is 1 micron;

[0116] The filter pore size of the separation layer is 10 microns;

[0117] The support layer is composed of parts by weight:

[0118] Aggregate: 50 parts coal powder, 15 parts phenolic resin, 30 parts white carbon black, 9 parts bentonite, 4 parts burnt kaolin;

[0119] Pore-forming agent: 1 part of Zimujie, 0.8 part of serpentine powder;

[0120] Additives: 2 parts of copper nitrate, 4 parts of fatty acid modified calcium carbonate;

[0121] Dispersant: 1.2 parts of lecithin.

[0122] The preparation steps of the separation layer are:

[0123] Ingredients: Prepare 20 parts of white carbon black, 30 parts of coal powder and 1 part of purple wood knot by weight;

[0124] Coating liquid solvent preparation: weigh and mix glycerol, ethylene glycol and 1,4-butanediol in a volume ratio of 15: 16:18;

[0125] Separation layer slurry preparation: first ...

Embodiment 3

[0129] The inorganic carbon membrane includes a support layer and a separation layer;

[0130] The thickness of the separation layer is 0.05 microns;

[0131] The ratio of the thickness of the separation layer to the thickness of the support layer is 1:100; the filter pore size of the separation layer is 20nm;

[0132] The separation layer is formed by multiple coatings, thereby obtaining the pore diameter gradient of the support layer, the inner layer of the separation layer, and the outer layer of the separation layer that gradually become smaller;

[0133] A water-producing channel is formed between the flat-plate inorganic carbon film and the inorganic carbon film arranged side by side, and the ratio of the thickness of the flat-plate inorganic carbon film to the height of the water-producing channel is 1:4.

[0134] The support layer is composed of parts by weight:

[0135] Aggregate: 45 parts of coal powder, 13 parts of phenolic resin, 22 parts of white carbon black, 6 parts of ben...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com