Multilevel-structured VS4 nano-powder, and preparation method and application thereof

A nano-powder, hydrothermal reaction technology, applied in nanotechnology, structural parts, chemical instruments and methods, etc., can solve the problems of harsh synthesis conditions of vanadium tetrasulfide, difficult to control reaction, slow research progress, etc. High purity and crystallinity, and uniform chemical composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] A multilevel structure VS 4 The preparation method of nanopowder, comprises the following steps:

[0023] Step 1: Weigh the vanadium source and sulfur source material, dissolve the vanadium source and sulfur source material in 40-80mL deionized water, control the molar ratio of vanadium and sulfur to 1:1-1:2, magnetically stir or ultrasonically disperse for 10 Solution A was obtained after ~60 min, and the concentration of the vanadium source was 0.06-0.6 mol / L. The vanadium source is one or more of sodium metavanadate, sodium vanadate, ammonium metavanadate, vanadium pentoxide and potassium metavanadate. The sulfur source is one or more of thioacetamide, sodium diethylthiocarbamate and sulfur element.

[0024] Step 2: Transfer solution A to the hydrothermal reaction liner, install an external kettle and place it in a homogeneous reactor, control the filling ratio of the hydrothermal reaction to 40-80%, and synthesize at a temperature of 160-200°C Under reaction 12 ~...

Embodiment 1

[0028] Step 1: Weigh sodium metavanadate and thioacetamide, dissolve them in 60mL of deionized water, control the molar ratio of vanadium and sulfur to 1:1, obtain solution A after magnetic stirring for 60min, and the concentration of vanadium source is 0.06mol / L.

[0029] Step 2: Transfer the solution A to the hydrothermal reaction liner, install an external kettle and place it in a homogeneous reactor, control the filling ratio of the hydrothermal reaction to 60%, and react at a synthesis temperature of 180°C for 24 hours.

[0030] Step 3: After the hydrothermal reaction is completed and cooled naturally, the reaction product is taken out, washed 3 times with water and 3 times with alcohol, collected, and dried at 60°C for 12 hours to obtain the multi-level structure VS 4 Nano powder. Wherein, the washing method is suction filtration washing, and the collection method is suction filtration collection.

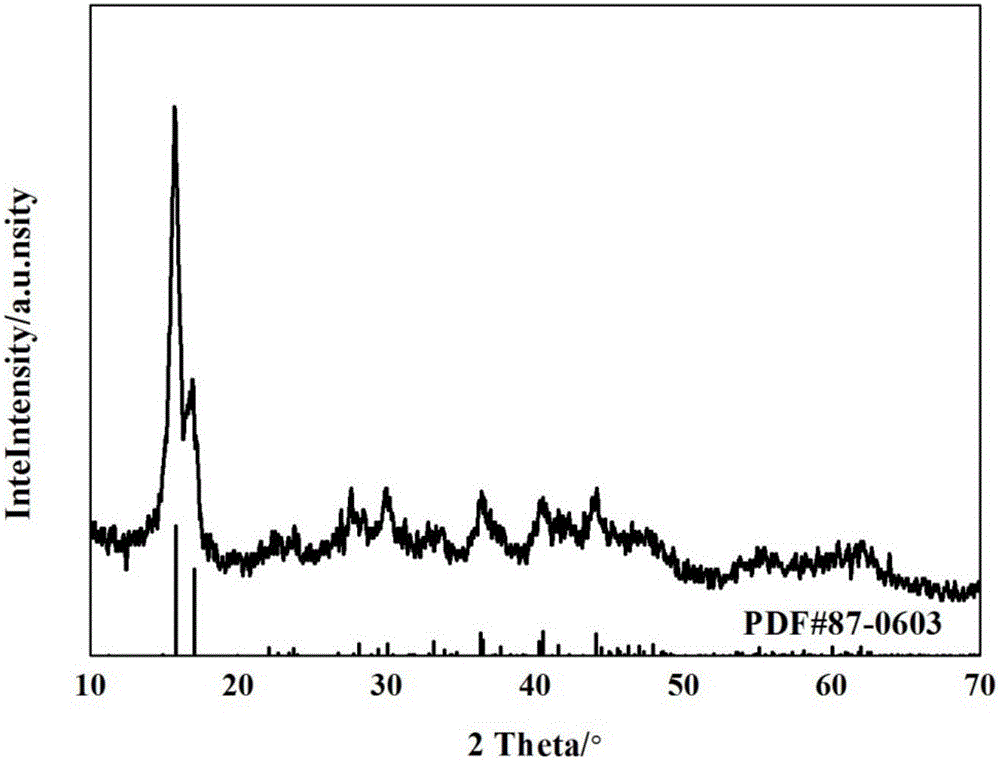

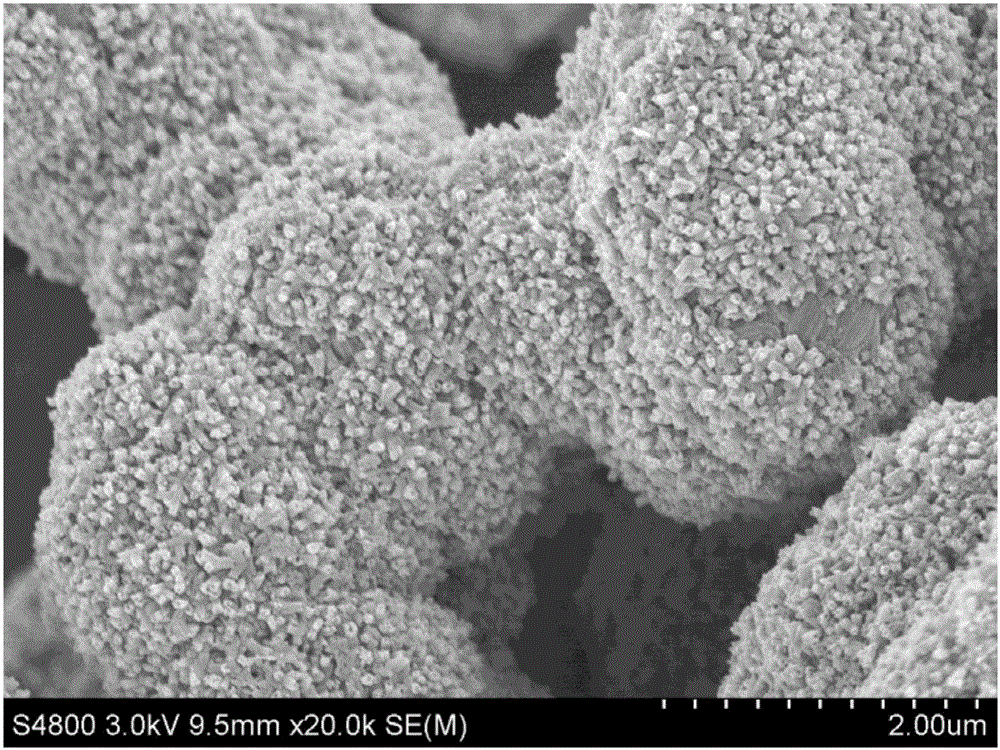

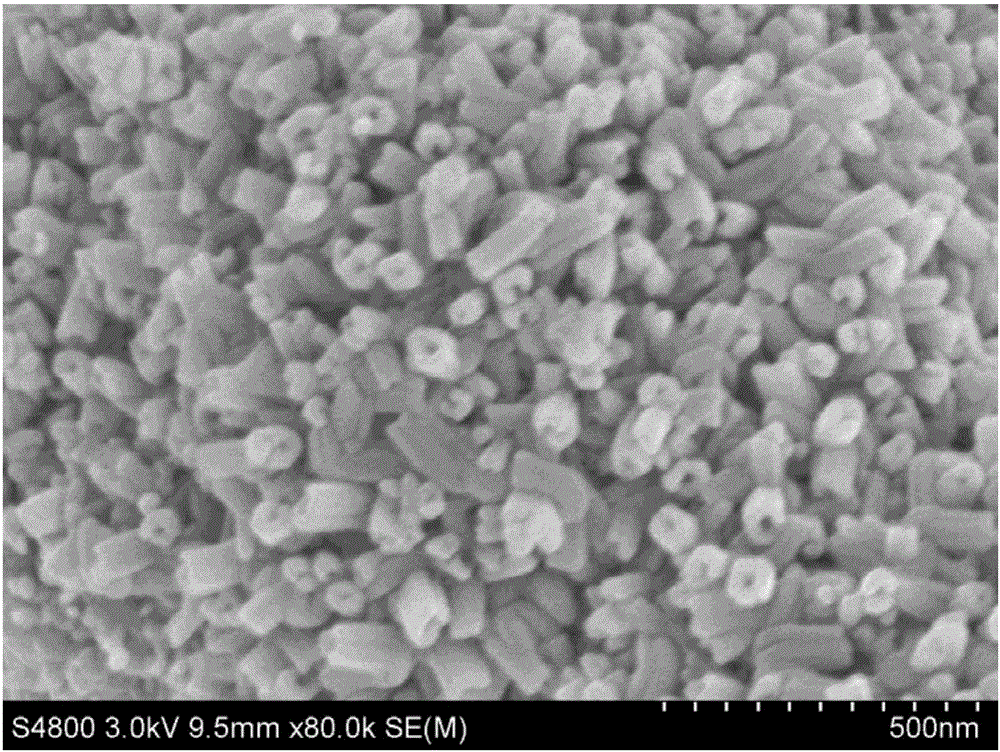

[0031] from figure 1 It can be seen that all X-ray powder diffractio...

Embodiment 2

[0034] Step 1: Weigh sodium metavanadate and thioacetamide, dissolve in 40mL deionized water, control the molar ratio of vanadium and sulfur to 1:1.5, obtain solution A after ultrasonic dispersion for 10min, and the concentration of vanadium source is 0.1mol / L.

[0035] Step 2: Transfer the solution A to the hydrothermal reaction liner, install an external kettle and place it in a homogeneous reactor, control the filling ratio of the hydrothermal reaction to 80%, and react for 12 hours at a synthesis temperature of 160°C.

[0036]Step 3: After the hydrothermal reaction is completed and cooled naturally, the reaction product is taken out, washed twice with water and twice with alcohol, collected, and dried at 80°C for 6 hours to obtain the multi-level structure VS 4 Nano powder. Wherein, the washing method is suction filtration washing, and the collection method is suction filtration collection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com