Manufacturing process of stainless steel door

A manufacturing process and technology for stainless steel doors, applied in the field of stainless steel doors, can solve problems such as poor waterproof performance, stainless steel doors are susceptible to external corrosion, and the surface spray coating falls off, so as to improve adhesion, avoid falling, and improve waterproof performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

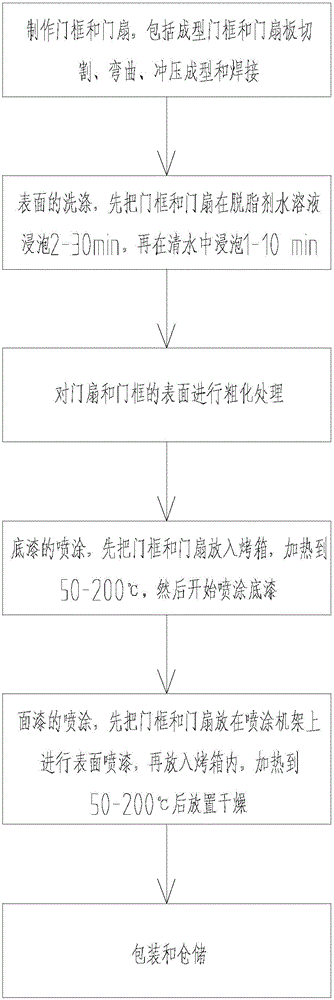

[0021] refer to figure 1 As shown, the present invention provides a kind of manufacturing process of stainless steel door, comprises the following steps:

[0022] Step 1. Make the door frame and door leaf, including cutting, bending, stamping and welding of the formed door frame and door leaf; this process mainly includes cutting, embossing, frame pressing, bending, punching, Boundary angle, foaming and other processes. The main step of this step also includes setting decorative grooves on the surface of the door frame, filling the decorative grooves with decorative stripes, and the decorative stripes can increase the aesthetics of the stainless...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com