Coal ash catalyst and preparing method and application thereof

A technology for fly ash and catalyst, which is applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve the problems of complicated process flow, high cost, difficult sources, etc., and achieves simple process flow and convenient industrial application. , the effect of increasing the basic position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

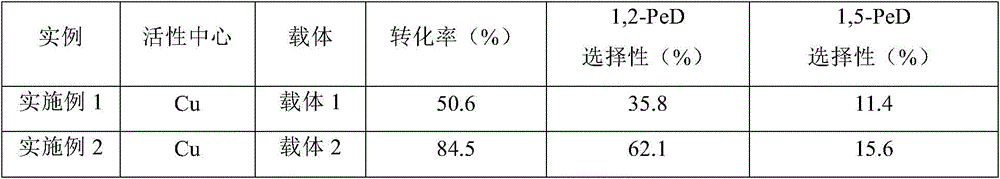

Embodiment 1

[0036] The catalyst was prepared by impregnation method. First, take 2.0g of fly ash before treatment as carrier 1, add 100ml of 2mmol / L Cu(NO 3 ) 2 In the solution, after stirring and heating to 50°C, immerse for 24 hours. Afterwards, use a rotary evaporator to dry to obtain a solid powder, put the powder in a muffle furnace, and bake it at a constant temperature of 450° C. for 8 hours, then take it out and grind it. At a temperature of 250° C., the calcined powder was reductively activated in a hydrogen atmosphere for 5 hours to obtain the catalyst 1 used in the present invention.

[0037] Place the prepared catalyst in a 100mL autoclave, add 60mL of a mixture of furfural and ethanol (mass ratio of furfural to ethanol is 1:4), pass in nitrogen gas to exhaust the air, then pass in hydrogen gas and hold the pressure to 3Mpa , heated to 120°C, and stirred for 6 hours to obtain the reaction product. The conversion rate of furfural and the selectivity of 1,2-pentanediol and 1,...

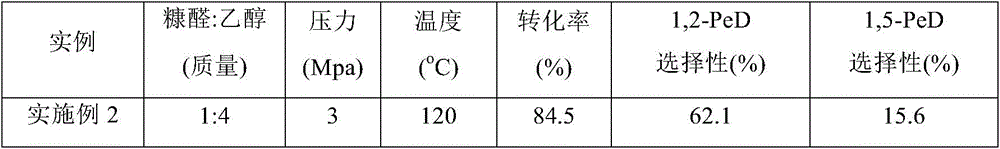

Embodiment 2

[0039] The catalyst was prepared by impregnation method. First, a certain amount of fly ash was placed in a muffle furnace and activated at a constant temperature of 550°C for 3 hours. The calcined powder is added to the pre-prepared 0.2mol / L sodium hydroxide solution, heated and stirred for 1.5 hours, dried and calcined to activate the fly ash to obtain the spare carrier 2. Get 2.0g carrier 2 and add 100ml2mmol / L of Cu(NO 3 ) 2 In the solution, after stirring and heating to 50°C, immerse for 24 hours. Afterwards, use a rotary evaporator to dry to obtain a solid powder, put the powder in a muffle furnace, and bake it at a constant temperature of 450° C. for 8 hours, then take it out and grind it. At a temperature of 250° C., the calcined powder was reductively activated in a hydrogen atmosphere for 5 hours to obtain the catalyst 2 used in the present invention.

[0040] Place the prepared catalyst in a 100mL autoclave, add 60mL of a mixture of furfural and ethanol (furfura...

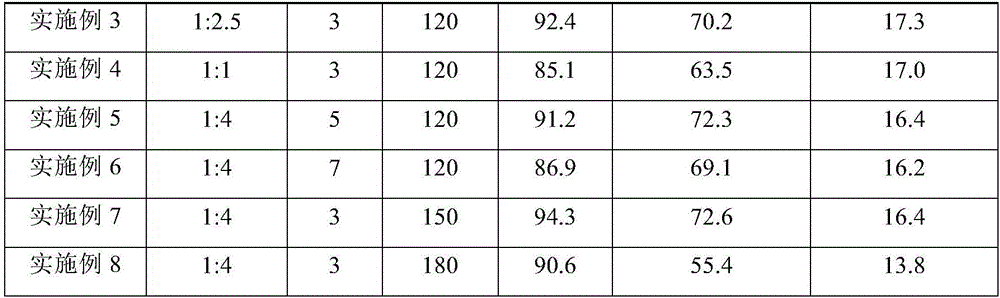

Embodiment 3

[0044] The operation steps are as described in Example 2, the mass ratio of furfural and ethanol in the 60mL reaction solution is changed to 1: 2.5, and the reaction product is obtained after the reaction. Alcohol selectivity is listed in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com