An energy-saving steamer

A technology of steamer and steam drum, which is applied in the direction of steam cooking utensils, plug-ins, heating devices, etc., which can solve the problems of slow steam diffusion speed, poor temperature gradient, and large temperature gradient difference of steamer, and achieve fast steam diffusion speed , reduce the temperature gradient difference, shorten the effect of steaming time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

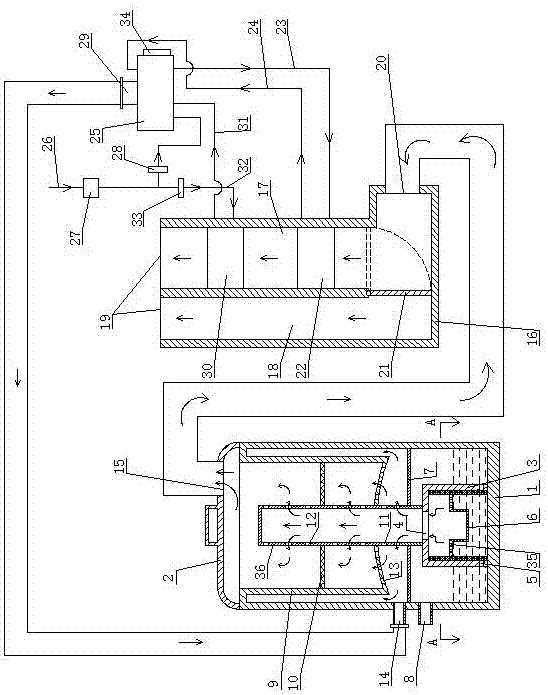

[0013] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

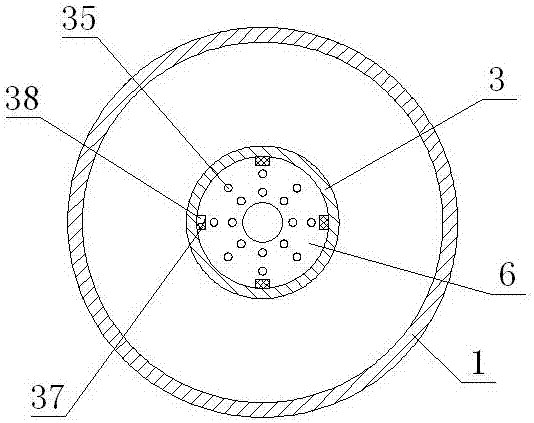

[0014] Such as Figure 1 ~ Figure 2 As shown, the present invention comprises a cage body 1 and a cage cover 2. A heating chamber 3 is provided at the center of the inner bottom of the cage body 1. The top center of the heating chamber 3 is provided with a fourth steam outlet 4. Several water inlet holes 5 are arranged. A movable plate 6 slidingly connected to its side wall is arranged in the heating chamber 3 . The middle part of the movable plate 6 is concave, and several fifth steam outlet holes 35 are evenly distributed on the movable plate 6 along the outer circumferential direction of the concave portion. A plurality of slide bars 37 are arranged at intervals on the inner wall of the heating chamber 6 , and a plurality of slide grooves 38 slidingly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com