Inertia piezoelectric driver

A piezoelectric driver, inertial technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve the complex structure and poor applicability of miniature piezoelectric driver. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

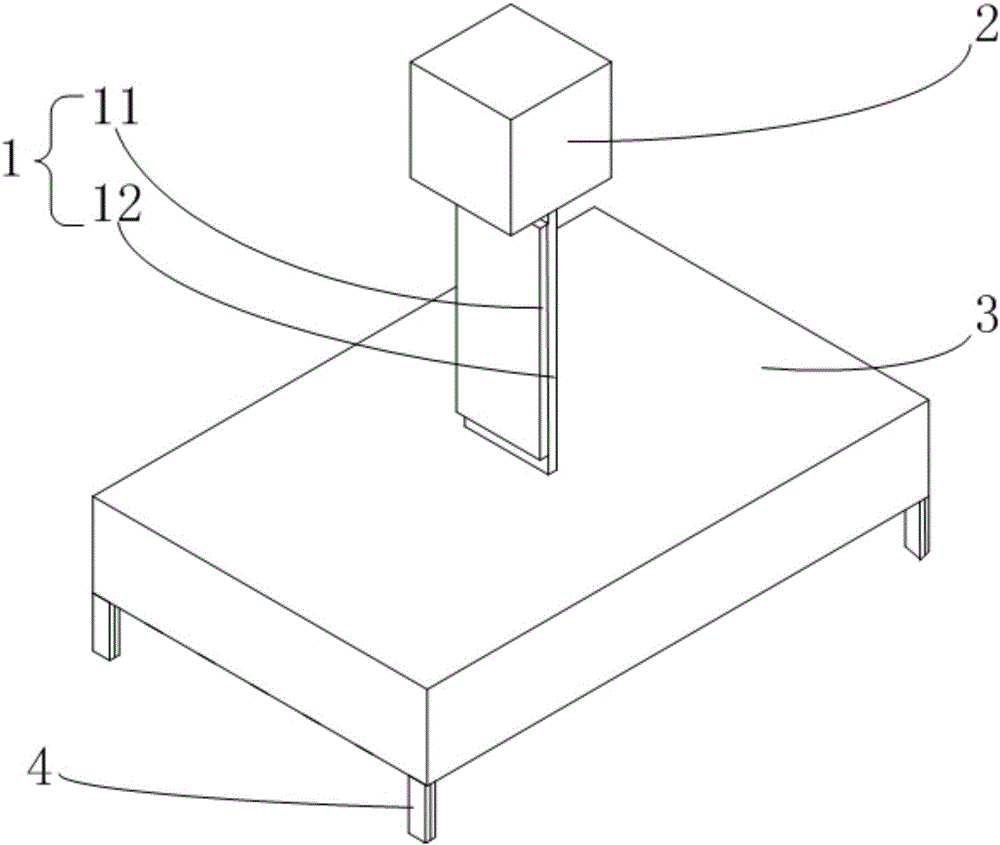

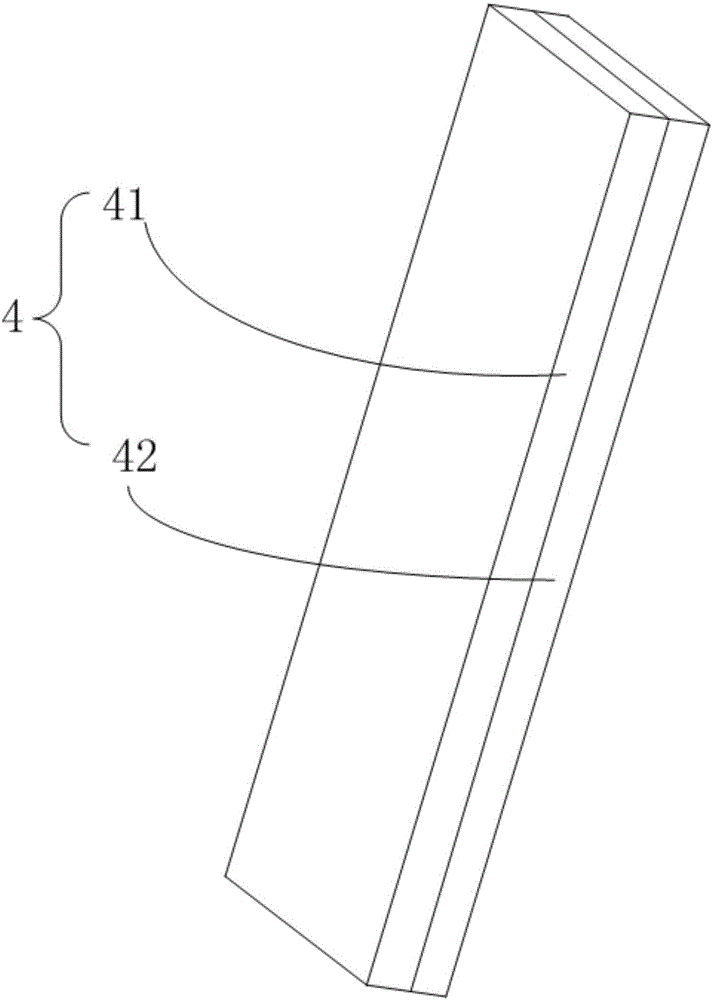

[0011] refer to figure 1 and figure 2 , an inertial piezoelectric actuator of the present invention, comprising a piezoelectric vibrator 1, a mass block 2 and a base 3, characterized in that it also includes a composite cantilever 4, wherein: the two ends of the piezoelectric vibrator 1 are respectively fixedly connected to the mass on the block 2 and the base 3; the composite cantilever 4 is a thin sheet structure and is composed of a high-friction elastic material 41 and a low-friction elastic material 42, and the high-friction elastic material 41 and the low-friction elastic material 42 are sheet-type structures and have the same size. The friction coefficient of the high-friction elastic material 41 is greater than that of the low-friction elastic material 42. The four composite cantilevers 4 are arranged on the lower surface of the base 3, and all of them The low-friction elastic material 42 faces the same side; the piezoelectric vibrator 1 is formed by bonding the pie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com