Nitrogen-doped carbon-coated molybdenum selenide/graphene core-shell array sandwich structure composite material, preparation method and application thereof

A nitrogen-doped carbon, sandwich structure technology, used in structural parts, electrical components, battery electrodes, etc., to achieve high rate performance, excellent rate performance, and high cycle stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Disperse and dissolve 4mmol of selenium powder in 10mL of hydrazine hydrate, and stir for 30min at room temperature 25℃ to form a wine-red solution A. The concentration of selenium in solution A is 0.4mmolmL -1 ;

[0038] (2) Dissolve 2mmol of sodium molybdate dihydrate in 60mL of deionized water to form solution B. The concentration of sodium molybdate in solution B is 0.33mmolmL -1 ;

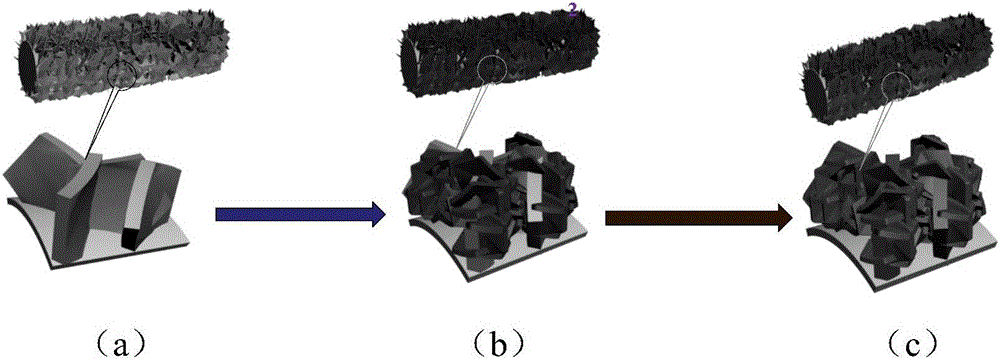

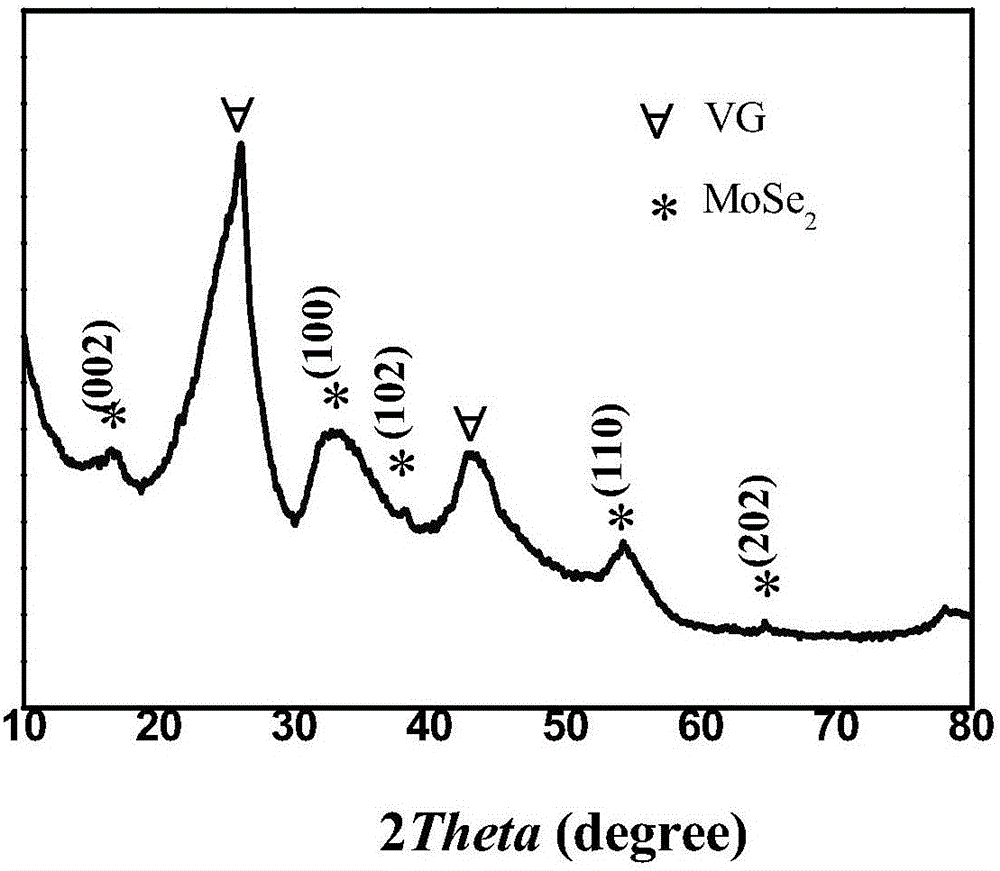

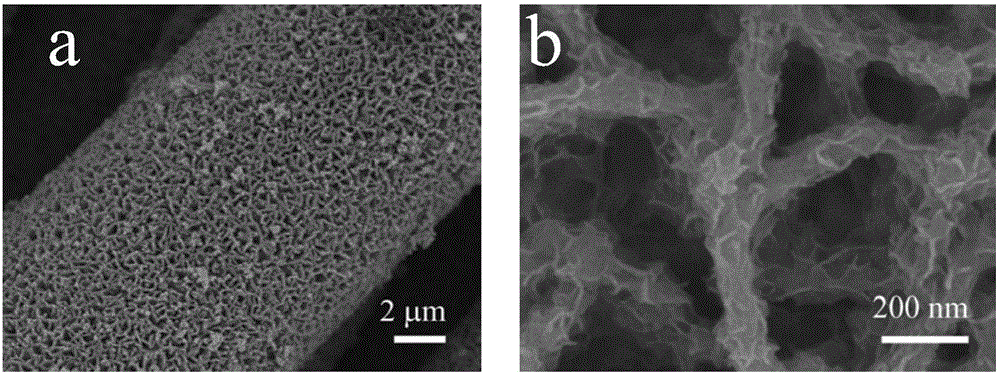

[0039] (3) Take 10mL of solution A and 60mL of solution B, mix and stir evenly, transfer to the reactor, and then place 5×5cm vertical graphene (VG) collector material grown on carbon cloth in it, 200℃ water Thermal reaction for 24 hours, washing and drying to obtain VG-MoSe 2 Core-shell array structure;

[0040] (4) Weigh 0.2g of dopamine hydrochloride and dissolve it in 30mL deionized water to form a solution, and then add VG-MoSe 2 The core-shell array structure is immersed in it, polymerized in a water bath at 80°C for 24 hours, washed and dried to obtain a core-shell array composite m...

Embodiment 2

[0048] (1) Disperse and dissolve 3mmol of selenium powder in 10mL of hydrazine hydrate, and stir for 30min at room temperature 25℃ to form a wine-red solution A. The concentration of selenium in solution A is 0.3mmolmL -1 ;

[0049] (2) Dissolve 1.5mmol of sodium molybdate dihydrate in 50mL of deionized water to form solution B. The concentration of sodium molybdate in solution B is 0.03mmolmL -1 ;

[0050] (3) Take 10mL of solution A and 50mL of solution B, mix and stir evenly, transfer to the reactor, and then place 3×3cm vertical graphene (VG) collector material grown on carbon cloth in it, 200℃ water Heat reaction for 16 hours, wash and dry to obtain VG-MoSe 2 Core-shell array structure;

[0051] (4) Weigh 0.15g of dopamine hydrochloride and dissolve it in 30mL deionized water to form a solution, and then add VG-MoSe 2 The core-shell array structure is immersed in it, polymerized in a water bath at 80°C for 18 hours, washed and dried to obtain a core-shell array composite materia...

Embodiment 3

[0057] (1) Disperse and dissolve 6mmol of selenium powder in 10mL of hydrazine hydrate, and stir for 30min at room temperature to form a wine-red solution A. The concentration of selenium in solution A is 0.6mmolmL -1 ;

[0058] (2) Dissolve 3mmol of sodium molybdate dihydrate in 60mL of deionized water to form solution B. The concentration of sodium molybdate in solution B is 0.05mmolmL -1 ;

[0059] (3) Take 10mL of solution A and 60mL of solution B, mix and stir them evenly, transfer them to the reactor, and then place the 6×6cm vertical graphene (VG) collector material grown on carbon cloth in it, 200℃ water Thermal reaction for 12 hours, washing and drying to obtain VG-MoSe 2 Core-shell array structure;

[0060] (4) Weigh 0.3g of dopamine hydrochloride and dissolve it in 30mL deionized water to form a solution, and then add VG-MoSe 2 The core-shell array structure is immersed in it, polymerized in a water bath at 80°C for 12 hours, washed and dried to obtain a core-shell array c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com