Bi<3+>,B<3+> doped copper fluoride positive electrode material coated by gradient structure and used for lithium battery and preparation method thereof

A positive electrode material, copper fluoride technology, applied in battery electrodes, structural parts, circuits, etc., can solve the problems of insufficient stability of copper fluoride materials, electrochemical performance attenuation, and low electronic conductivity, so as to improve the comprehensive electrochemical performance. Performance, improvement of electronic conductivity, effect of improvement of ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

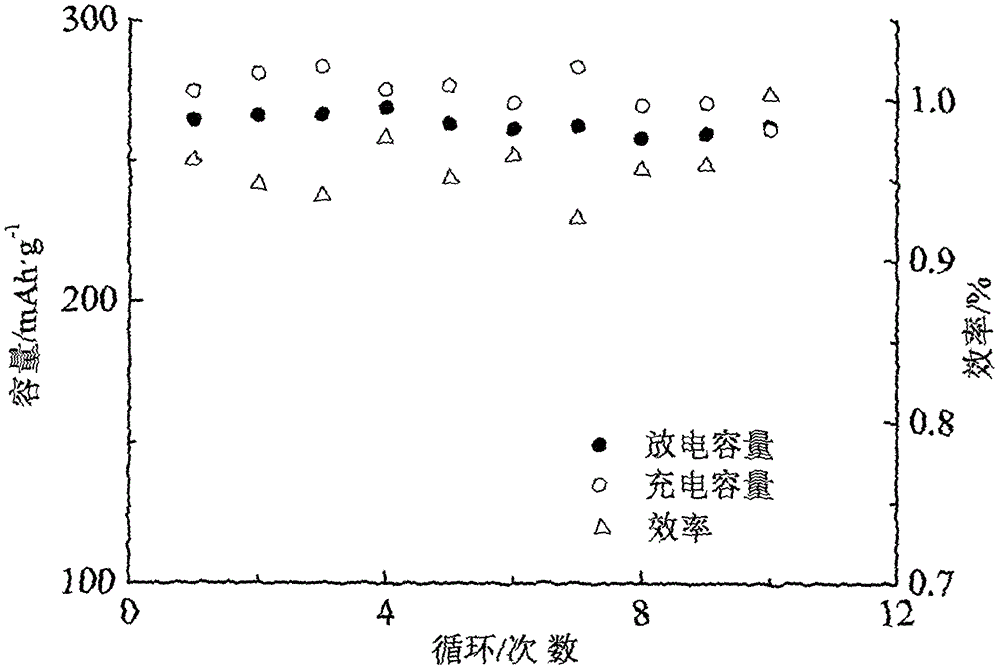

Embodiment 1

[0015] Embodiment 1: the ammonium fluoride of anhydrous copper sulfate, the amount of anhydrous copper sulfate substance 3.0 times, the amount of anhydrous copper sulfate substance 2% bismuth nitrate pentahydrate, the amount of anhydrous copper sulfate substance 0.5% boric acid, no Water copper sulfate quality 0.9% glycerol and ethylene glycol are put into thermostatic ball mill after mixing the mixed liquid of 1: 1 with volume ratio, anhydrous copper sulfate quality 0.9% polyquaternium-7, regulate the temperature of ball mill as 60°C, the mass ratio of the ball mill to the material is 20:1, ball mill at a speed of 200 rpm for 10 hours, take out the material after ball milling, wash with ethanol three times, and dry in a 100°C drying oven for 10 hours to prepare Bi 3+ , B 3+ Doped with copper fluoride; bismuth nitrate pentahydrate and ammonium fluoride with a mass ratio of 1:3.0, Bi with a mass of 80 times the total mass of bismuth nitrate pentahydrate and ammonium fluoride 3...

Embodiment 2

[0016] Embodiment 2: the amount of anhydrous copper sulfate, anhydrous copper sulfate substance 3.3 times ammonium fluoride, the amount of anhydrous copper sulfate substance 5% bismuth nitrate pentahydrate, the amount of anhydrous copper sulfate substance 0.7% boric acid, no Water copper sulfate quality 2.5% glycerol and ethylene glycol are put into thermostatic ball mill after mixing the mixed liquid of 1: 1, anhydrous copper sulfate quality 2.5% polyquaternium-7 with volume ratio, regulate the temperature of ball mill as 70°C, the mass ratio of the ball mill to the material is 20:1, ball mill at a speed of 300 rpm for 15 hours, take out the material after ball milling, wash with ethanol three times, and dry in a drying oven at 110°C for 16 hours to prepare Bi 3+ , B 3+ Doped with copper fluoride; bismuth nitrate pentahydrate and ammonium fluoride with a mass ratio of 1:3.3, Bi with a mass of 150 times the total mass of bismuth nitrate pentahydrate and ammonium fluoride 3+ ,...

Embodiment 3

[0017] Embodiment 3: the amount of anhydrous copper sulfate, anhydrous copper sulfate substance 3.5 times ammonium fluoride, the amount of anhydrous copper sulfate substance 10% bismuth nitrate pentahydrate, the amount of anhydrous copper sulfate substance 1% boric acid, no Water copper sulfate quality 4.5% glycerol and ethylene glycol are put into thermostatic ball mill after mixing the mixed liquid of 1: 1 with volume ratio, anhydrous copper sulfate quality 4.5% polyquaternium-10, regulate the temperature of ball mill as 80°C, the mass ratio of the ball mill to the material is 20:1, ball mill at a speed of 400 rpm for 20 hours, take out the material after ball milling, wash with ethanol three times, and dry in a drying oven at 120°C for 20 hours to prepare Bi 3+ , B 3+ Doped with copper fluoride; bismuth nitrate pentahydrate and ammonium fluoride with a mass ratio of 3.6, Bi with a mass of 170 times the total mass of bismuth nitrate pentahydrate and ammonium fluoride 3+ , B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com