High-gloss, high-hardness, easily-scrubbed and scrubbing-resistant metal material

A technology of metal materials and raw materials, which is applied in the fields of easy-to-clean, high-gloss, scrub-resistant metal materials, and high hardness. It can solve problems such as large surface voids, soft paint films, and white space when wiped, and achieve hardness and scratch resistance. The effect of high hardness and smooth hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

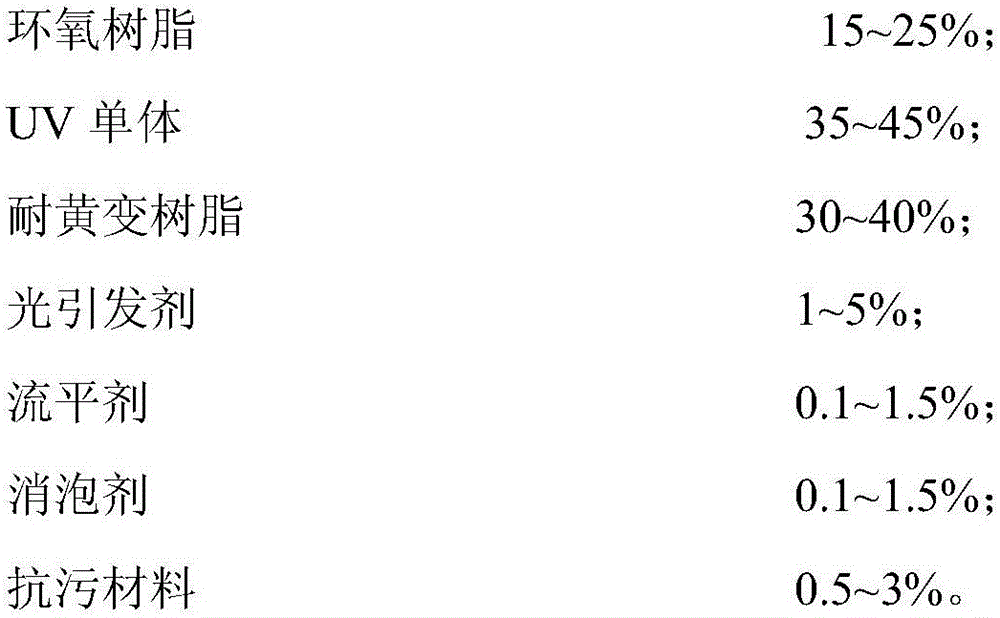

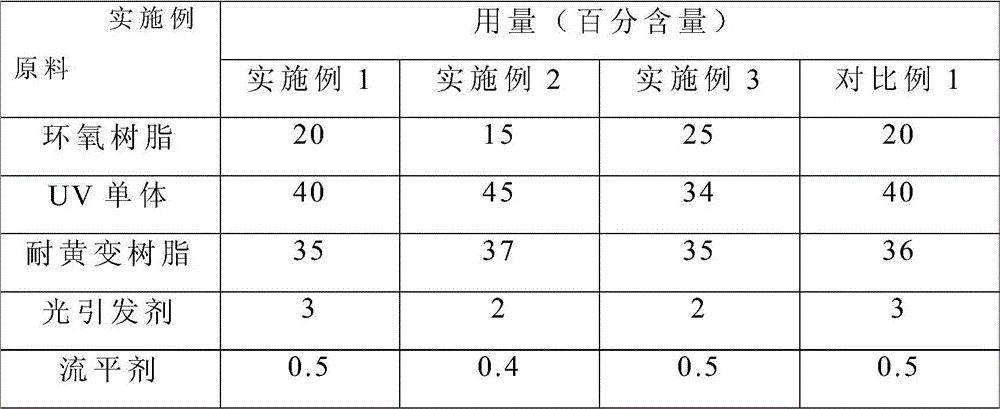

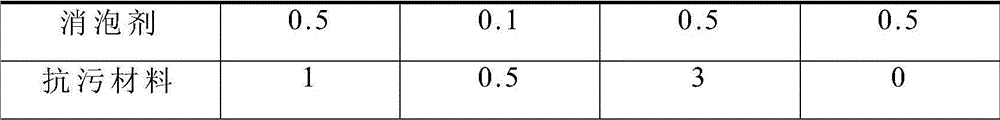

[0030] This embodiment provides a kind of writing tablet, comprises substrate, is arranged on the undercoat layer on both sides of substrate, is arranged on the topcoat layer on wherein one side undercoat layer and is arranged on the protective coating layer on topcoat layer, and this substrate is metal board, the coating used in the protective coating is a UV curable coating, and the raw materials and consumption of the coating are shown in Table 1, wherein:

[0031] Epoxy resin was purchased from Baling Petrochemical Company.

[0032] The UV monomer is epoxy acrylic resin, purchased from Suzhou Southeast Chemical Co., Ltd.

[0033] Anti-yellowing resin is aliphatic isocyanate, purchased from Suzhou Southeast Chemical Co., Ltd.

[0034] The photoinitiator was benzophenone, purchased from Suzhou Southeast Chemical Co., Ltd.

[0035] The antifouling material is silicone, purchased from Suzhou Southeast Chemical Co., Ltd.

[0036] Leveling agent and defoamer were purchased fr...

Embodiment 2

[0040] This embodiment provides a writing board. The raw materials and dosage of the paint used for the protective coating in the writing board are shown in Table 1. The raw materials except for the UV monomer are the same as those in Embodiment 1.

[0041] The UV monomer is a modified epoxy acrylic resin.

Embodiment 3

[0043] This embodiment provides a writing board. The raw materials and dosage of the paint used for the protective coating in the writing board are shown in Table 1. The raw materials other than the antifouling material are the same as those in Embodiment 1.

[0044] The antifouling material is silane coupling agent KH5500, purchased from Suzhou Southeast Chemical Co., Ltd.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com