Preparation of silicon dioxide microsphere with nonionic/anionic-combined-type surfactant as soft template

A surfactant and silica technology, which is applied in the preparation of non-ionic/anion-bound surfactants as soft templates and the preparation of silica hybrid microspheres, can solve the problem of small pore size and wall thickness of materials, Limit the application of microspheres, etc., to achieve the effects of increased solubility, improved antistatic, and uniform space size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

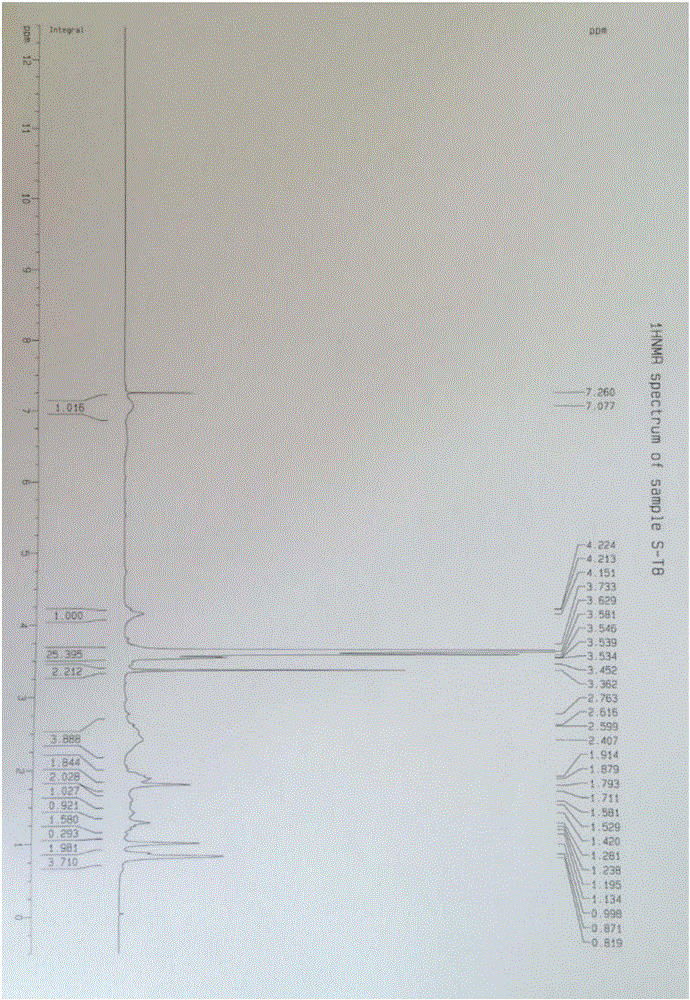

[0050] 1. Synthesis of star-shaped hybrid arm polymers

[0051] (1) Synthesis of polymethyl methacrylate (PMMA): 6.25 g of methyl methacrylate, 0.375 g of RAFT reagent, 0.0125 g of AIBN, and 12.5 mL of toluene were charged into a flask. Perform freeze degassing several times. Polymerization was carried out at 60°C for 4 hours. Quench with liquid nitrogen. The mixed solution after polymerization is poured into petroleum ether to separate out linear polymer.

[0052] (2) Synthesis of poly(methoxypolyethylene glycol acrylate) (P(PEGMEA)): 12.5g methoxypolyethylene glycol acrylate, 0.375g RAFT reagent, 0.0125gAIBN, 12.5mL toluene were loaded into a flask . Perform freeze degassing several times. Polymerization was carried out at 60°C for 1 hour. Quench with liquid nitrogen. The mixed solution after polymerization is poured into petroleum ether to separate out linear polymer.

[0053] (3) Synthesis of poly(methyl methacrylate block styrene) (P(MMA-b-St)): 5 g of polymethyl ...

Embodiment 2

[0066] 1. Synthesis of star-shaped hybrid arm polymers

[0067] (1) Synthesis of polymethyl methacrylate (PMMA): 12.5 g of methyl methacrylate, 0.455 g of RAFT reagent, 0.0205 g of AIBN, and 12.5 mL of toluene were charged into a flask. Perform freeze degassing several times. Polymerization was carried out at 70°C for 4 hours. Quench with liquid nitrogen. The mixed solution after polymerization is poured into petroleum ether to separate out linear polymer.

[0068] (2) Synthesis of poly(methoxypolyethylene glycol acrylate) (P(PEGMEA)): 15 g of methoxypolyethylene glycol acrylate, 0.0455 g of RAFT reagent, 0.0205 g of AIBN, and 12.5 mL of toluene were charged into a flask. Perform freeze degassing several times. Polymerization was carried out at 70°C for 1 hour. Quench with liquid nitrogen. The mixed solution after polymerization is poured into petroleum ether to separate out linear polymer.

[0069] (3) Synthesis of poly(methyl methacrylate block styrene) (P(MMA-b-St)):...

Embodiment 3

[0081] 1. Synthesis of star-shaped hybrid arm polymers

[0082] (1) Synthesis of polymethyl methacrylate (PMMA): 12.5 g of methyl methacrylate, 0.455 g of RAFT reagent, 0.0205 g of AIBN, and 12.5 mL of toluene were charged into a flask. Perform freeze degassing several times. Polymerization was carried out at 70°C for 3 hours. Quench with liquid nitrogen. The mixed solution after polymerization is poured into petroleum ether to separate out linear polymer.

[0083] (2) Synthesis of poly(methoxypolyethylene glycol acrylate) (P(PEGMEA)): 15 g of methoxypolyethylene glycol acrylate, 0.0455 g of RAFT reagent, 0.0205 g of AIBN, and 12.5 mL of toluene were charged into a flask. Perform freeze degassing several times. Polymerization was carried out at 70°C for 2 hours. Quench with liquid nitrogen. The mixed solution after polymerization is poured into petroleum ether to separate out linear polymer.

[0084] (3) Synthesis of poly(methyl methacrylate block styrene) (P(MMA-b-St))...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com