Fine boring cutter

A fine boring and cutting tool technology, applied to fine boring cutters. It can solve the problems of product boring efficiency reduction, incomplete positioning, and small adjustment range, etc., and achieve good market prospects and economic value, good surface processing accuracy, and improved connection accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

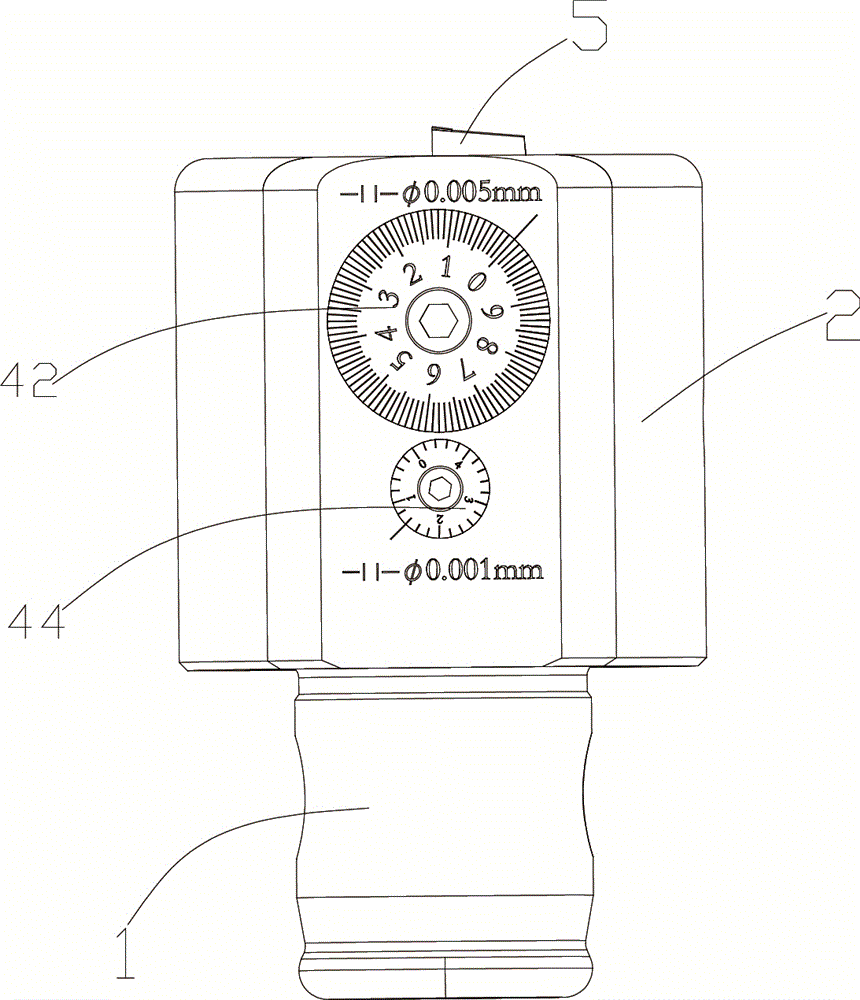

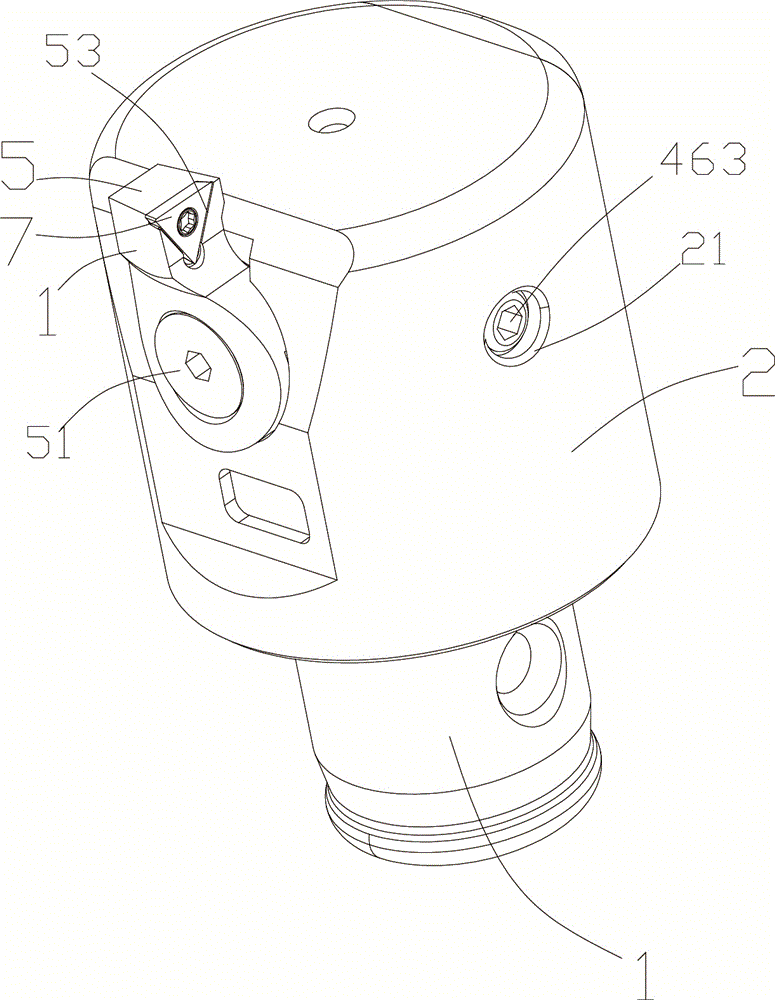

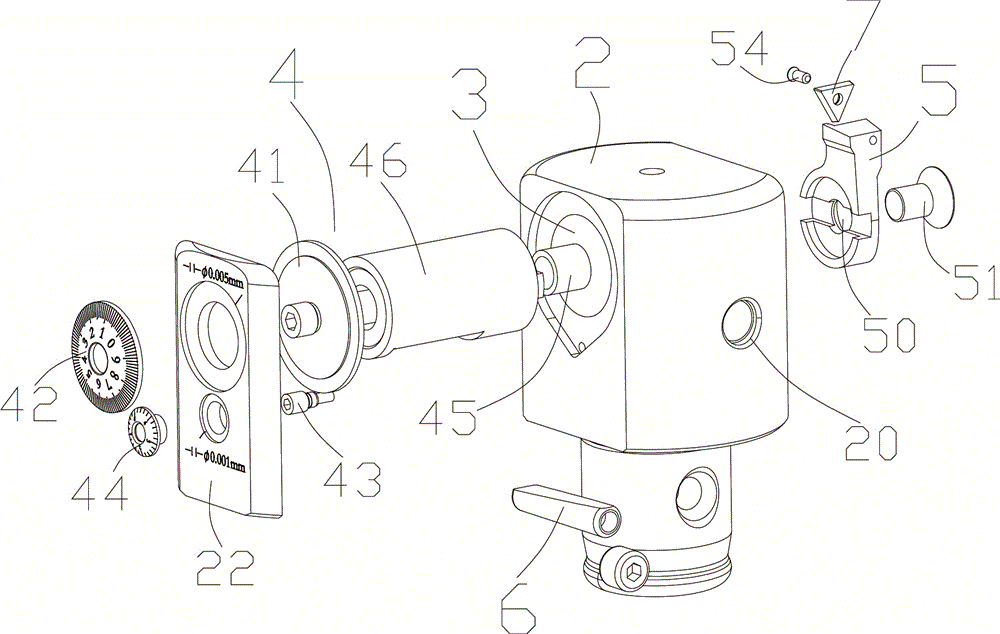

[0021] see Figure 1 to Figure 5 Shown, a specific embodiment of the fine boring tool of the present invention. A fine boring tool, comprising a round handle 1 inserted into a machine tool and a tool body 2, a through hole 3 extending radially is arranged on the tool body 2, a fine adjustment device 4 is arranged in the through hole 3, the fine adjustment One end of the device 4 is connected with a blade seat 5, the fine-tuning device 4 includes a driven adjustment screw 41, and one end of the driven adjustment screw 41 is provided with a driven adjustment dial 42, and the driven adjustment screw 41 is connected to a driving Adjusting screw rod 43 cooperates, and one end of described active adjusting screw rod 43 is provided with active adjusting dial 44, also includes being arranged on the other end of described driven adjusting scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com