Preparation method and application of copper sulfide nanocapsule particle

A technology of nano-capsules and copper sulfide, which is applied in the directions of non-active ingredient medical preparations, medical preparations containing active ingredients, capsule delivery, etc., can solve the problems of limited practical application, no copper sulfide, complicated steps, etc., and achieves good results. The effect of drug loading, less energy consumption, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

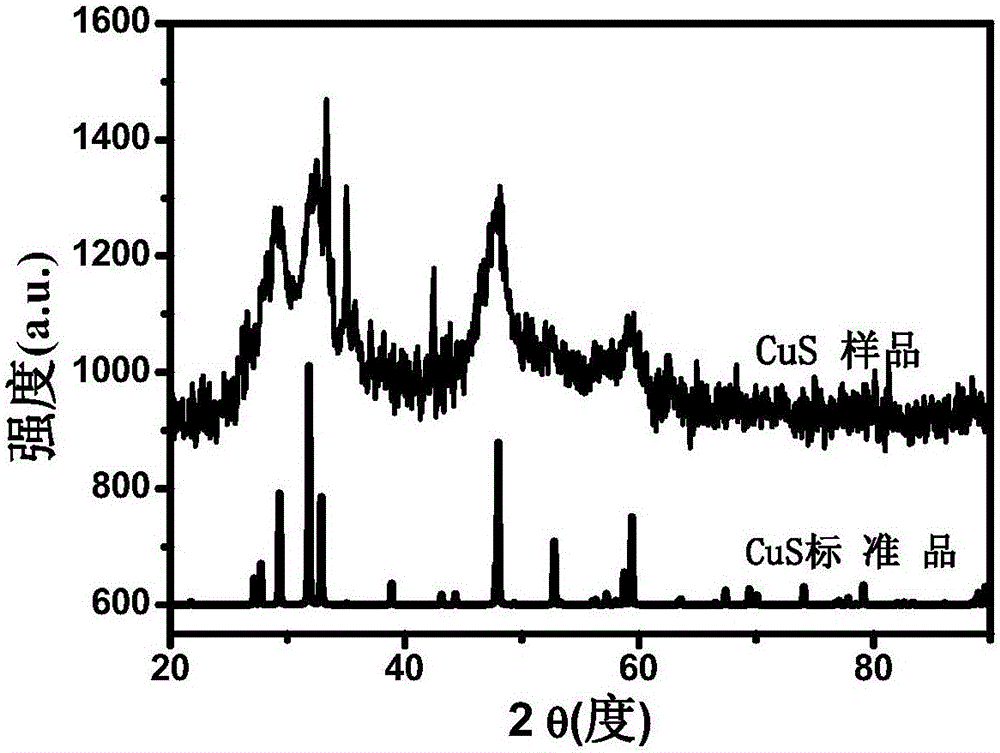

Embodiment 1

[0034] Weigh 0.3mmol of L-cysteine and dissolve in 150mL double distilled water, 0.4mmol of Cu(NO 3 ) 2 ·3H 2 O was dissolved in 50mL double distilled water, dissolved evenly, and Cu(NO 3 ) 2 Add the solution dropwise to the lysine solution, stir with a magnetic stirrer at room temperature for 30 minutes; weigh 0.3mmol of Na 2 S 2 o 3 Dissolve in 2mL double-distilled water, dissolve evenly, add dropwise to the above mixture, the mixture turns dark brown; heat the above solution to 90°C and react for 120min; after the reaction, centrifuge at 5000rpm for 10min, wash with double-distilled water for 3 times, and dry to obtain Black precipitate.

[0035] Prepare the obtained black precipitates into 0.125, 0.25, 0.5, and 1mg / mL CuS-Cy solutions respectively, and use 1W / cm 2 The power is irradiated for 6 minutes, and the temperature change is tested every 10 seconds. Dissolve 5 mg of CuS-Cy nanocapsules in 10 mL of PBS, stir evenly, add 5 mg DOX and dissolve in the above so...

Embodiment 2

[0041] Weigh 0.2mmol of L-cysteine and dissolve in 150mL double distilled water, 0.4mmol of Cu(NO 3 ) 2 ·3H 2 O was dissolved in 50mL double distilled water, dissolved evenly, and Cu(NO 3 ) 2 Add the solution dropwise to the lysine solution, stir with a magnetic stirrer at room temperature for 30 minutes; weigh 0.3mmol of Na 2S 2 o 3 Dissolve in 2mL double-distilled water, dissolve evenly, add dropwise to the above mixture, the mixture turns dark brown; heat the above solution to 90°C and react for 120min; after the reaction, centrifuge at 5000rpm for 10min, wash with double-distilled water for 3 times, and dry to obtain The black precipitate is copper sulfide nanocapsule particles.

[0042] The properties of the copper sulfide nanocapsule particles prepared in this example are similar to those in Example 1, and will not be repeated here.

Embodiment 3

[0044] Weigh 0.1mmol of L-cysteine and dissolve in 150mL double distilled water, 0.4mmol of Cu(NO 3 ) 2 ·3H 2 O was dissolved in 50mL double distilled water, dissolved evenly, and Cu(NO 3 ) 2 Add the solution dropwise to the lysine solution, stir with a magnetic stirrer at room temperature for 60 minutes; weigh 0.3mmol of Na 2 S 2 o 3 Dissolve in 2mL double-distilled water, dissolve evenly, add dropwise to the above mixture, the mixture turns dark brown; heat the above solution to 90°C and react for 120min; after the reaction, centrifuge at 5000rpm for 10min, wash with double-distilled water for 3 times, and dry to obtain The black precipitate is copper sulfide nanocapsule particles.

[0045] The properties of the copper sulfide nanocapsule particles prepared in this example are similar to those in Example 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com