Fermentation grape extract, preparing method of fermentation grape extract and preparation containing fermentation grape extract

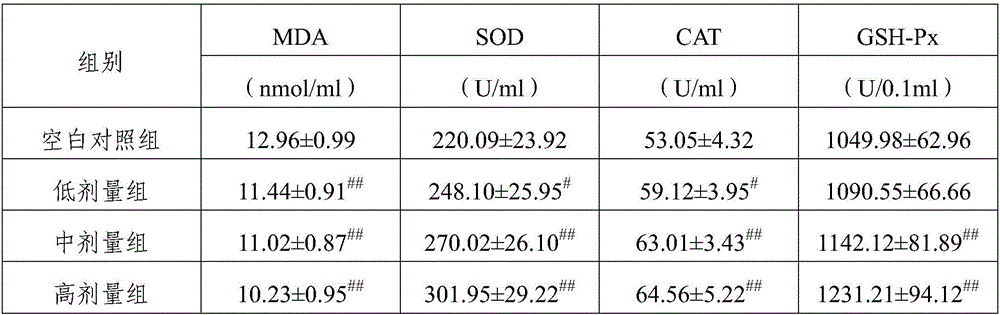

A technology for extracts and grapes, which is applied in the field of fermented grape extracts and its preparation and preparations containing them, can solve the problems of no relevant patents on grape polyphenols, and achieve the effects of novel technology, improved extraction rate, and enhanced antioxidant enzyme activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Example 1 Fermented Grape Extract

[0052] The preparation method comprises the following steps:

[0053] 1) Wash and crush whole grape raw materials (including grape vines, grape leaves, grape stems, grape skins, grape seeds, etc.)

[0054] 2) filtering the fermented liquid to obtain filtrate A;

[0055] 3) drying and pulverizing the filtered filter residue, adding 80% ethanol which is 8 times the dry weight of the filter residue, extracting at room temperature for 4 hours, and filtering to obtain an extract;

[0056]4) combining the filtrate A and the extract, concentrating to dryness, and obtaining the crude extract of fermented grapes;

[0057] 5) dissolving the obtained crude extract in a mixture of ethanol and ethyl acetate with a volume ratio of 2:3, filtering, discarding the filter residue, and obtaining filtrate B;

[0058] Pass the filtrate B through the macroporous adsorption resin column D-101, elute with a mixture of ethanol and ethyl acetate with a volu...

Embodiment 2

[0061] Example 2 Fermented Grape Extract

[0062] The preparation method comprises the following steps:

[0063] 1) Wash and crush whole grape raw materials (including grape vines, grape leaves, grape stems, grape skins, grape seeds, etc.)

[0064] 2) filtering the fermented liquid to obtain filtrate A;

[0065] 3) drying and pulverizing the filtered filter residue, adding 70% ethanol which is 8 times the dry weight of the filter residue, extracting at room temperature for 4 hours, and filtering to obtain an extract;

[0066] 4) combining the filtrate A and the extract, concentrating to dryness, and obtaining the crude extract of fermented grapes;

[0067] 5) dissolving the obtained crude extract in a mixture of ethanol and ethyl acetate with a volume ratio of 2:3, filtering, discarding the filter residue, and obtaining filtrate B;

[0068] Pass the filtrate B through the macroporous adsorption resin column D-101, elute with a mixture of ethanol and ethyl acetate with a vol...

Embodiment 3

[0071] Example 3 Tablet containing the fermented grape extract of Example 1

[0072] Composition of raw and auxiliary materials: Example 1 fermented grape extract 25kg, starch 4.8kg, magnesium stearate 125g.

[0073] Preparation method: take the fermented grape extract of Example 1, grind it into fine powder, pass through a 100-mesh sieve, use 50% starch slurry as a binder, granulate and dry in a one-step granulator, add magnesium stearate, Mix well, compress into tablets, and coat with sugar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com