Execution mechanism of shakeproof hammer reset device for overhead lines

A technology of actuators and anti-vibration hammers, which is applied in the direction of overhead lines/cable equipment, motor tools, manufacturing tools, etc., can solve the problems that robots cannot be widely used, the degree of modularization of mechanisms is not high, and the completion of functions is not ideal. Achieve the effect of improving the lack of low-speed rotating motor torque, strong adaptability of the mechanism, and avoiding slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

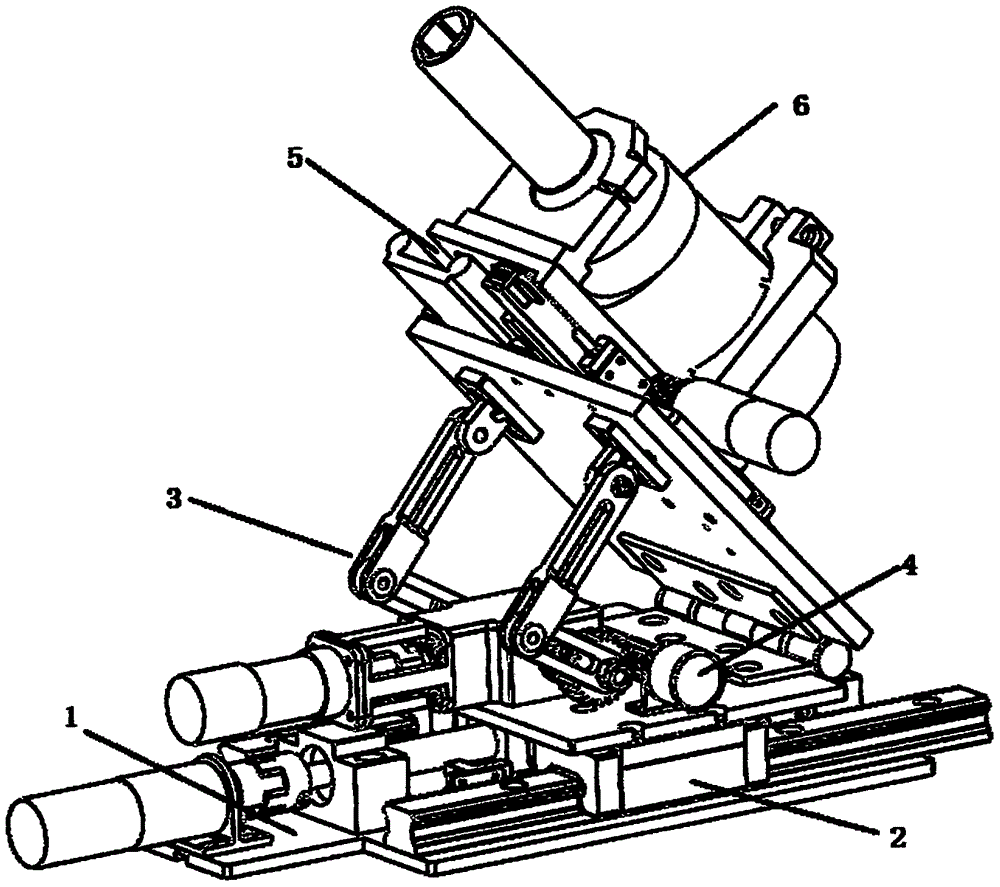

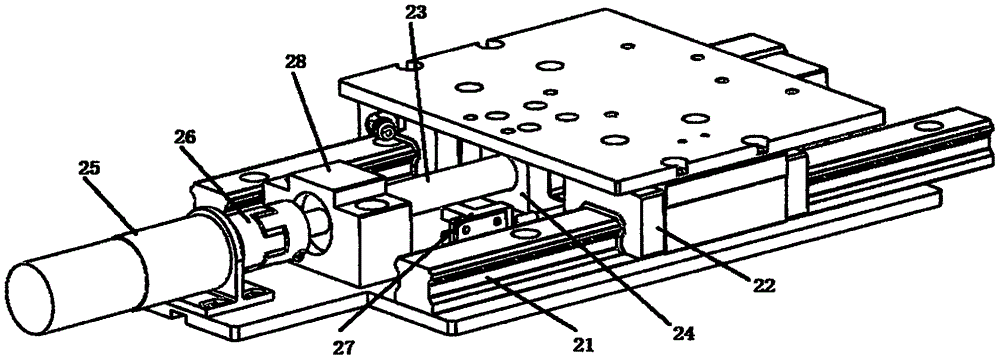

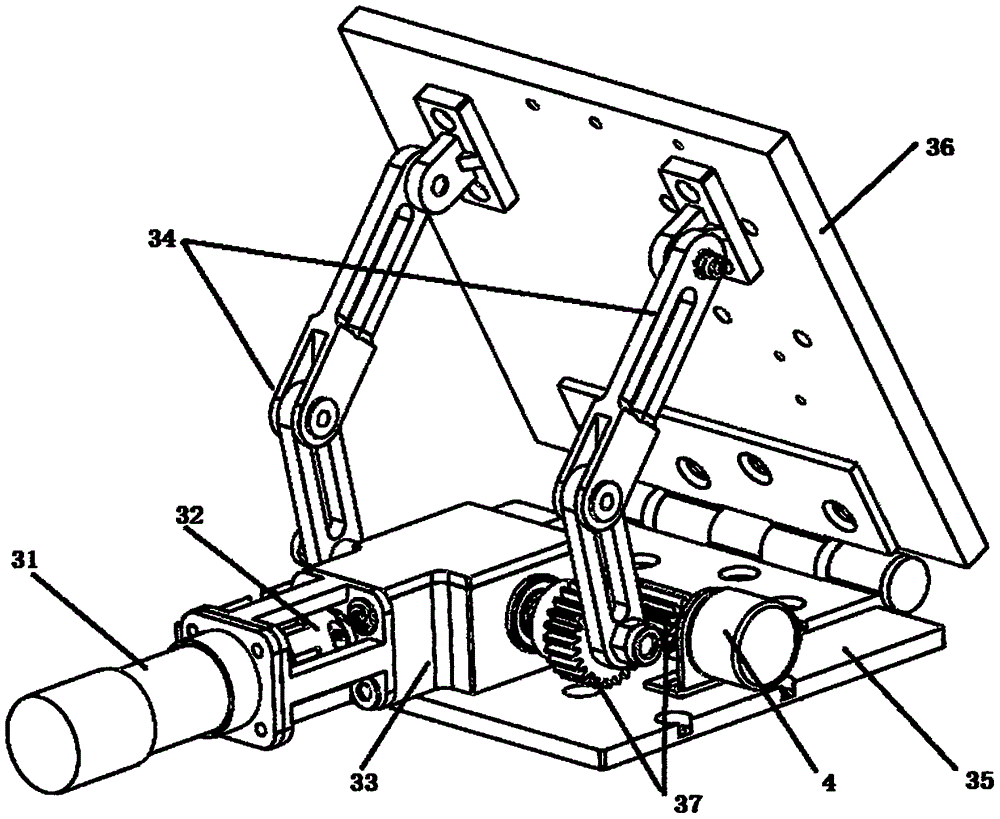

[0020] The technical solutions of the present invention will be further described below through the embodiments and in conjunction with the accompanying drawings. In the figure, the components indicated by each label are as follows: Mechanism base plate 1, one-degree-of-freedom mobile platform 2, pitch adjustment mechanism 3, potentiometer 4, feed mechanism 5, end actuator 6, linear slide rail 21, sliding Table 22, screw rod 23, slider 24, mobile platform DC motor 25, coupling 26, photoelectric switch 27, bearing seat 28, pitching mechanism DC reduction motor 31, coupling 32, 90-degree corner gearbox 33, parallel Working mechanism 34, lower support plate 35, upper support plate 36, potentiometer spur gear 37, gearbox case 41, input shaft 42, bevel gear 43, output shaft 44, feed mechanism DC reduction motor 51, gear 52, gear Bar 53, slide table 54, slide rail 55, photoelectric switch 56, camera 57.

[0021] The executive mechanism of the anti-vibration hammer resetter for over...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com