Two-dimensional continuous component sample, and preparing method and application thereof in quick determination of phase diagram high flux

A sample and sample block technology, applied in the field of materials, its preparation, and heterogeneous materials, can solve the problem of limiting the number of samples of different components, and achieve the effect of increasing the number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

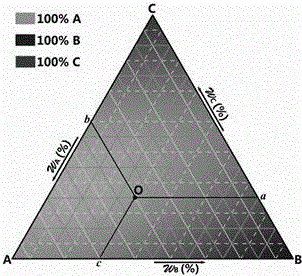

[0047] In this embodiment, see Figure 1~3 , The two-dimensional continuous composition sample takes the PbTe-PbSe-SrSe ternary system phase relationship as an example. First, the composition distribution should be prepared as figure 1 For the equilateral triangle thin slice sample shown, in order to meet the sampling needs of the scanning electron microscope, the side length of the sample is AB=BC=CA=10mm. Assuming that the three components of the phase diagram are A, B, and C, we also mark the three vertices of the triangle as A, B, and C at the same time. At the vertices, one of the three components is 100%, and the others The dual component is 0%. For example, at point A, the composition of component A is 100%, and the composition of component B and C is 0. At any point O on the triangle, we make three lines that pass through the point O and parallel to the three sides of the triangle. Suppose the intersections of these three lines with the AB, BC and CA sides are respecti...

Embodiment 2

[0055] This embodiment is basically the same as the first embodiment, and the special features are:

[0056] In this embodiment, the method for forming the two-dimensional continuous component sample is implemented by the solid-phase reaction method. The two-dimensional continuous component sample is formed by stacking three wedge-shaped powders with an angle of 120 degrees each other formed by three single components. It includes the following steps:

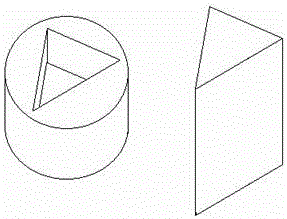

[0057] a. Use as figure 2 As shown in the mold with a triangular prism cavity, the cross section of the mold cavity is an equilateral triangle, and the bottom surface of the mold cavity is an equilateral triangle. A computer-controlled sampling system is used. Starting from the opposite side of vertex A of the equilateral triangle, fill the PbTe powder into the mold cavity. For the PbTe powder filled into the mold cavity, start from the vertex A of the triangle on the bottom of the cavity and be perpendicular to it. In the opposi...

Embodiment 3

[0062] This embodiment is basically the same as the previous embodiment, and the special features are:

[0063] In this embodiment, the two-dimensional continuous component sample still uses the PbTe-PbSe-SrSe ternary system phase relationship as an example. First, the component distribution should be prepared as shown in the attached file. figure 1 For the equilateral triangle sample shown, in order to meet the sampling needs of the scanning electron microscope, the side length of the sample is AB=BC=CA=10mm. Specifically to the PbTe-PbSe-SrSe ternary system, set x=Cb / AC, y=Ac / AB, z=Ba / BC, then the composition of any point on the sample triangle is (PbTe)x(PbSe)y(SrSe )z. The forming method of the two-dimensional continuous component sample is implemented by the 3d printing method, which specifically includes the following steps:

[0064] ① Choose a 3D printing system with 3 precise screw powder feeder channels, each channel conveys a single component powder of PbTe, PbSe or SrSe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com