Preparation method, product and application of flexible vanadium dioxide film

A vanadium dioxide and thin film technology, applied in the field of functional thin film preparation and application, can solve problems such as lattice mismatch, and achieve the effects of remarkable performance, simple process and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] A method for preparing a flexible vanadium dioxide film, characterized in that it comprises the steps of:

[0047] Step 1: Select the mica sheet as the substrate, and clean the mica sheet by peeling off the surface contamination layer;

[0048] Step 2: Place the mica sheet obtained in step 1 on the rotary heating table of the molecular beam epitaxy growth chamber; then close the molecular beam epitaxy growth chamber and vacuumize; the rotary table of the molecular beam epitaxy growth chamber has a heating function;

[0049] Step 3: Cover the mica substrate with the built-in baffle of the molecular beam epitaxy growth chamber, rotate the rotary table of the molecular beam epitaxy growth chamber horizontally and heat up until the mica sheet is heated to 500-650°C, keep the temperature and rotate;

[0050] Step 4: Install the vanadium source into the electron heat gun, and start the high-voltage electron beam generating module in the electron heat gun; the preferred elect...

Embodiment 1

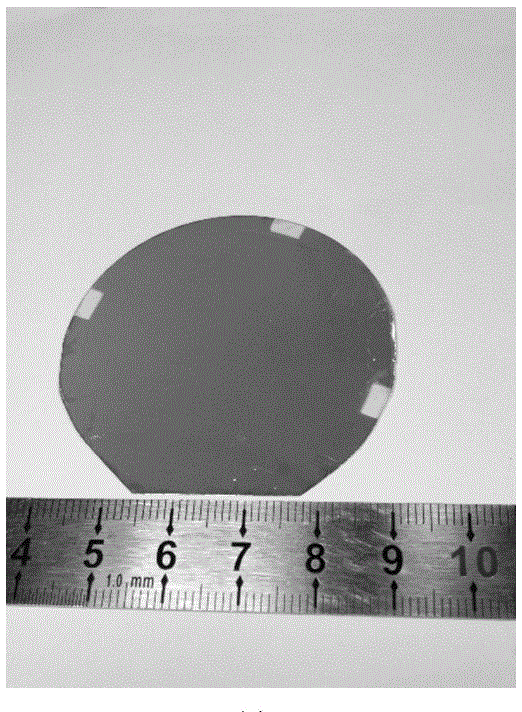

[0075] Select a 2-inch round mica as a substrate, and use tweezers or tape to peel off the mica surface contamination layer. Quickly put it into the sample chamber of the molecular beam epitaxy equipment.

[0076] Transfer the mica substrate to the growth chamber of the molecular beam epitaxy equipment. At this time, the vacuum degree of the growth chamber is 5.5×10 - 6 Pa, and then the substrate was rotated at a constant speed of 4 revolutions per minute, and at the same time, the substrate was heated at a heating rate of 30° C. / min, and the temperature was raised to 550° C.

[0077] Open the oxygen valve to feed high-purity oxygen with a purity of 6N (99.9999%), adjust the gas flow meter to keep the oxygen flow at 4.5 sccm, turn on the RF source, and adjust the RF power to fully dissociate oxygen into highly reactive oxygen atom beams. Turn on the electron gun for heating, evaporate the metal vanadium with a purity of 99.99% to produce a vanadium atom beam, and measure its...

Embodiment 2

[0082] Select a 2-inch round mica as a substrate, and use tweezers or tape to peel off the mica surface contamination layer. Quickly put it into the sample chamber of the molecular beam epitaxy equipment.

[0083] Transfer the mica substrate to the growth chamber of the molecular beam epitaxy equipment. At this time, the vacuum degree of the growth chamber is 5.5×10 - 6 Pa, and then the substrate was rotated at a constant speed of 4 revolutions per minute, and at the same time, the substrate was heated at a heating rate of 30° C. / min, and the temperature was raised to 550° C.

[0084] Open the oxygen valve to feed high-purity oxygen with a purity of 6N (99.9999%), adjust the gas flow meter to keep the oxygen flow at 4.5 sccm, turn on the RF source, and adjust the RF power to fully dissociate oxygen into highly reactive oxygen atom beams. Turn on the electron gun for heating, vaporize the metal vanadium with a purity of 99.99% to generate a vanadium atom beam, measure its rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Total thickness | aaaaa | aaaaa |

| Total thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com