Element N and O co-doped ti-based amorphous composite and preparation method thereof

A technology of amorphous composite materials and co-doping, which is applied in the field of titanium-based amorphous composite materials and their preparation, and can solve problems such as no performance advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

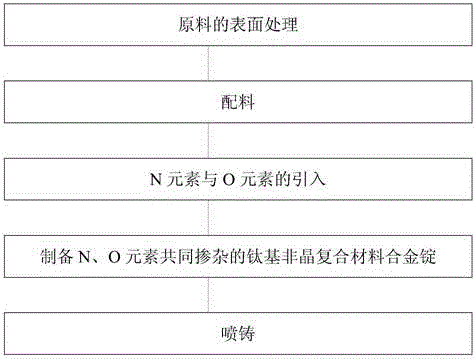

Method used

Image

Examples

Embodiment 1

[0036] This embodiment is a titanium-based amorphous composite material co-doped with N and O elements.

[0037] The titanium-based amorphous composite material co-doped with N and O elements described in this implementation example is composed of Ti, Zr, Nb, Cu, Be and doped interstitial elements N and O. The titanium-based amorphous composite material Atomic percent is Ti 48 Zr 20 Nb 12 Cu 5 be 15 , the addition amount of N element is 1000ppm, that is, the mass percentage of N element is 0.1%; the addition amount of O element is 1000ppm, that is, the mass percentage of O element is 0.1%. Among them, Ti, Zr, Nb, Cu, and Be are synthesized by smelting bulk Ti, Zr, Nb, Cu with purity ≥99.99% and bulk Be with purity ≥99%. N elements and O elements are added by adding TiN and TiO during the smelting process 2 Doping is introduced in powder form.

[0038] The specific process of preparing the titanium-based amorphous composite material co-doped with N and O elements propose...

Embodiment 2

[0050] This embodiment is a titanium-based amorphous composite material co-doped with N and O elements.

[0051] The titanium-based amorphous composite material co-doped with N and O elements described in this implementation example is composed of Ti, Zr, Nb, Cu, Be and doped interstitial elements N and O. The titanium-based amorphous composite material Atomic percent is Ti 48 Zr 20 Nb 12 Cu 5 be 15 , the addition amount of N element is 3000ppm, that is, the mass percentage of N element is 0.3%; the addition amount of O element is 2000ppm, that is, the mass percentage of O element is 0.2%. Among them, Ti, Zr, Nb, Cu, and Be are synthesized by smelting bulk Ti, Zr, Nb, Cu with purity ≥99.99% and bulk Be with purity ≥99%. N elements and O elements are added by adding TiN and TiO during the smelting process 2 Doping is introduced in powder form.

[0052] The specific process of preparing the titanium-based amorphous composite material co-doped with N and O elements propose...

Embodiment 3

[0063] This embodiment is a titanium-based amorphous composite material co-doped with N and O elements.

[0064] The titanium-based amorphous composite material co-doped with N and O elements described in this implementation example is composed of Ti, Zr, Nb, Cu, Be and doped interstitial elements N and O. The titanium-based amorphous composite material Atomic percent is Ti 48 Zr 20 Nb 12 Cu 5 be 15 , the addition amount of N element is 10000ppm, that is, the mass percentage of N element is 1%; the addition amount of O element is 2400ppm, that is, the mass percentage of O element is 0.24%. Among them, Ti, Zr, Nb, Cu, and Be are synthesized by smelting bulk Ti, Zr, Nb, Cu with purity ≥99.99% and bulk Be with purity ≥99%. N elements and O elements are added by adding TiN and TiO during the smelting process 2 Doping is introduced in powder form.

[0065] The specific process of preparing the titanium-based amorphous composite material co-doped with N and O elements propose...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com