Rapid Repair Polymer Mortar and Its Application

A technology for repairing mortar and polymer, used in road repair, roads, tracks, etc., can solve problems such as poor durability and poor toughness, and achieve the effects of reducing porosity, reducing shrinkage, and increasing deformability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] 1) Preparation of component A: 100 parts of modified epoxy resin, 15 parts of butyl glycidyl ether, 10 parts of dibutyl phthalate, 4 parts of inorganic nano-particle calcium carbonate, 0.1 parts of anti-aging agent p-phenylenediamine Components are added to the reaction kettle one by one and stirred for 10-15 minutes, and finally 400 parts of natural colored sand are added, stirred for 30 minutes, and degassed in a water bath to obtain component A, which is packaged and stored.

[0047] 2) Preparation of component B: add 10 parts of phenalkamine, 30 parts of polyetheramine, and 5 parts of accelerator DMP-30 into the reaction kettle and stir for 5-10 minutes, then defoam in a water bath to obtain component B, pack and store.

[0048] 3) Preparation of polymer mortar: put A and B into the mixing tank, and stir 0.1 part of epoxy resin defoamer for 10 minutes to obtain the polymer mortar, which is prepared as needed. Guaranteed to run out within 30 minutes after configurati...

Embodiment 2-8

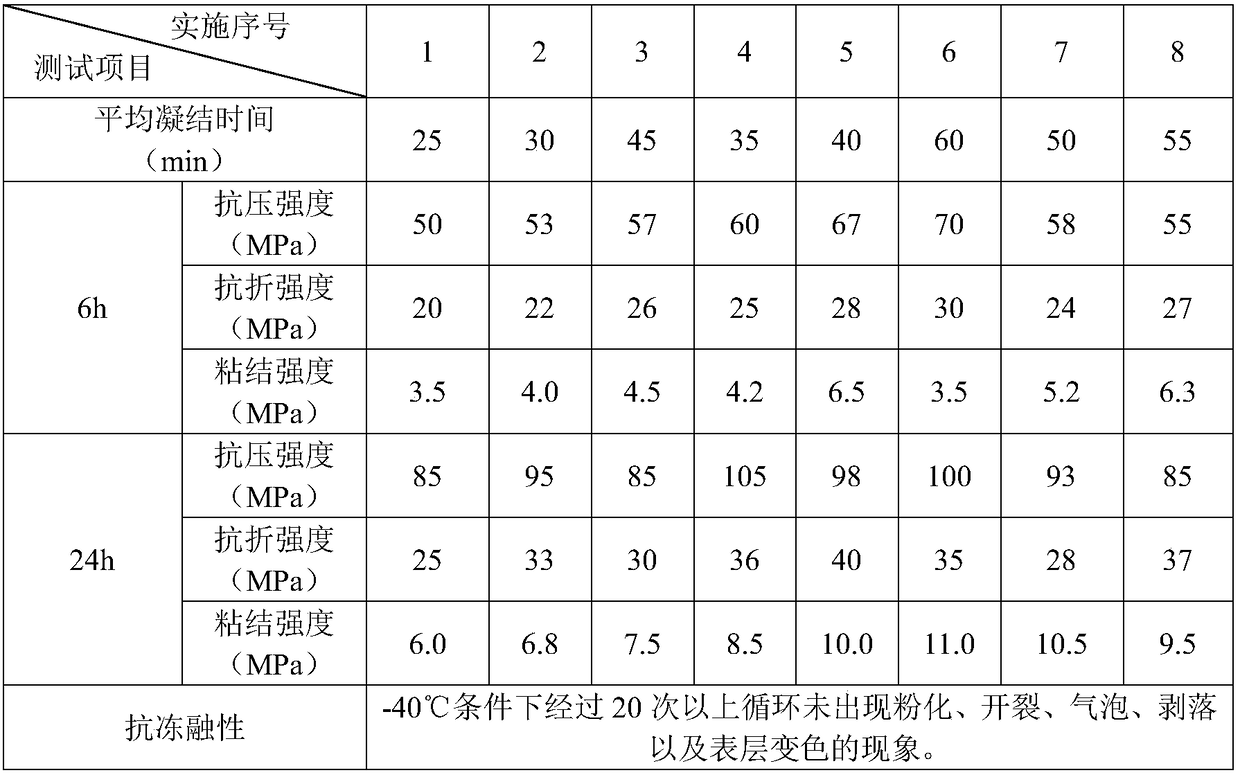

[0053] Examples 2-8, the preparation process of each component of the mortar is as in Example 1, and the types and materials of some additives in the polymer mortar are changed.

example 2

[0054] Example 2: Modified epoxy resin, natural colored sand, phenalkamine, polyetheramine, DMP-30, butyl glycidyl ether, xylene, epoxy resin defoamer, p-phenylenediamine. The proportioning ratio is 100:500:15:20:4:10:20:0.3:0.1 in parts by weight, and the test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com