Tunnel structure suitable for gypsum salt stratum and construction method

A technology for tunnel structure and strata, applied in tunnels, tunnel linings, underground chambers, etc., can solve problems such as collapse, tunnel lining cracking, safety accidents and property losses, reduce the possibility of corrosion, increase deformability, Enhanced anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with specific embodiments, so that those skilled in the art can understand.

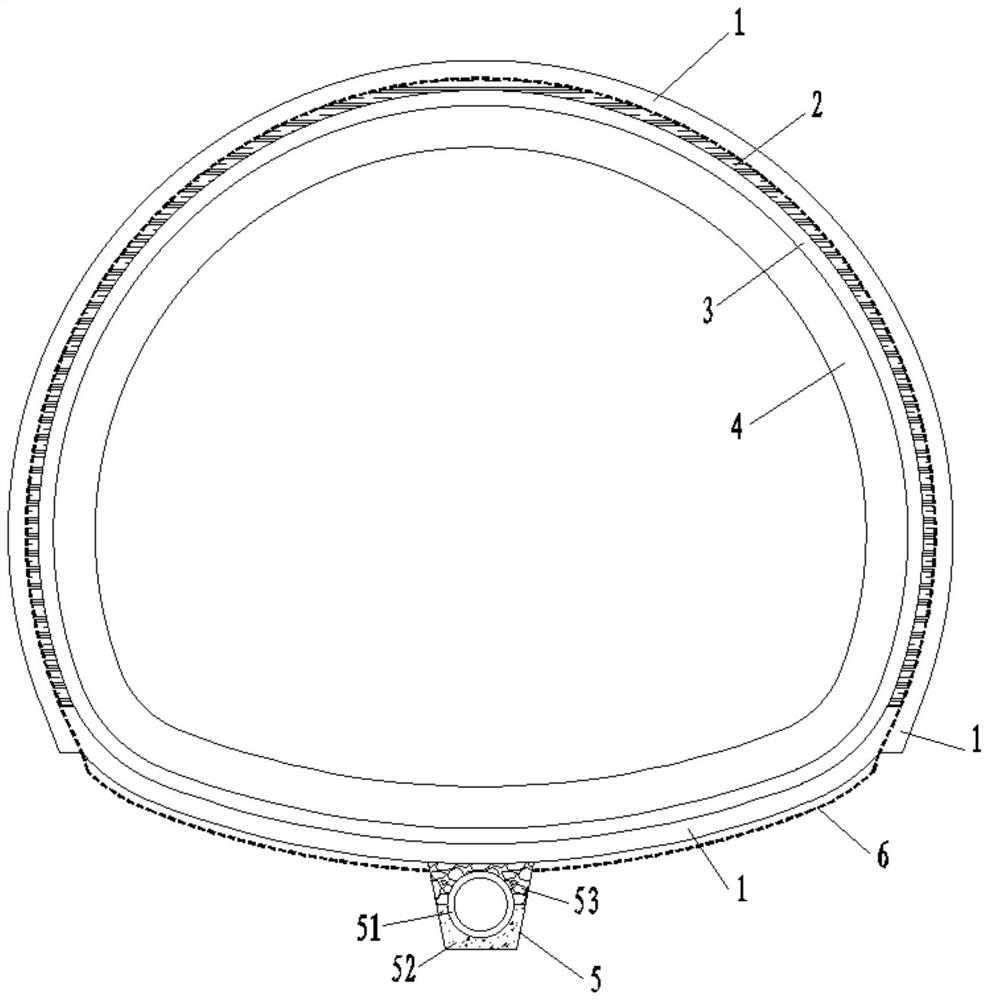

[0027] Such as figure 1 The tunnel structure shown is suitable for gypsum-salt stratum, which includes support layer 1, waterproof layer 3 and anti-corrosion lining 4 from outside to inside; support layer 1 is laid along the surrounding rock after excavation, and support layer 1 A deformation layer 2 is provided between the waterproof layer 3, and the deformation layer 2 is only arranged along the arch ring, no deformation layer is provided at the inverted arch, and the outer drainage system 5 is provided outside the center of the bottom of the support layer 1;

[0028] A circular drainage system 6 is set between the supporting layer 1 and the deformed layer 2, and the lower part of the annular drainage system 6 protrudes from between the supporting layer 1 and the deformed layer 2 and is arranged along the outer wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com