Novel cover plate

A cover plate, a new type of technology, applied in the field of solar energy materials, can solve the problems of cumbersome production process of the Pozier board, limited and fixed shape of the Pozier board, and increased slurry consumption, so as to save slurry raw materials and improve the overall qualification of the product The effect of efficiency and saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

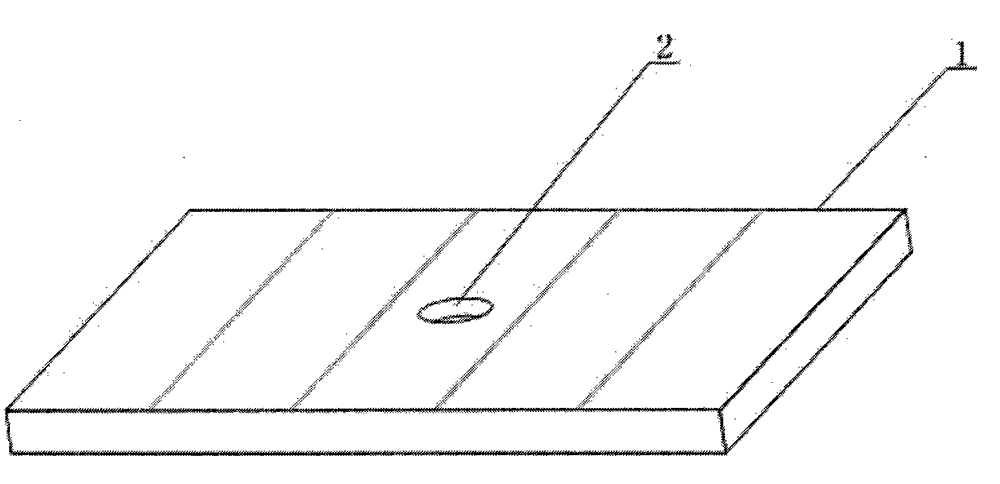

[0016] A novel cover plate is composed of a cover plate (1) and a material inlet (2). The feeding port (2) is at the very center of the cover plate (1).

[0017] When working: Cover the gypsum mold with the cover plate (1) after mold closing, install the funnel at the material inlet (2), and then pour the mixed slurry that has passed the test through the funnel (2) slowly and uniformly In the gypsum mold, after about 16 hours, the product is green-formed, and the cover plate (1) can be removed, demoulded, and enters the next process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com