Preparation method of porous carbon nanomaterial for adsorbing methylene blue

A technology of nanomaterials and methylene blue, which is applied in the field of preparation of porous carbon nanomaterials, can solve the problems of chemical reagent pollution, corrosive equipment, etc., and achieve the effects of short production process, easy raw materials and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

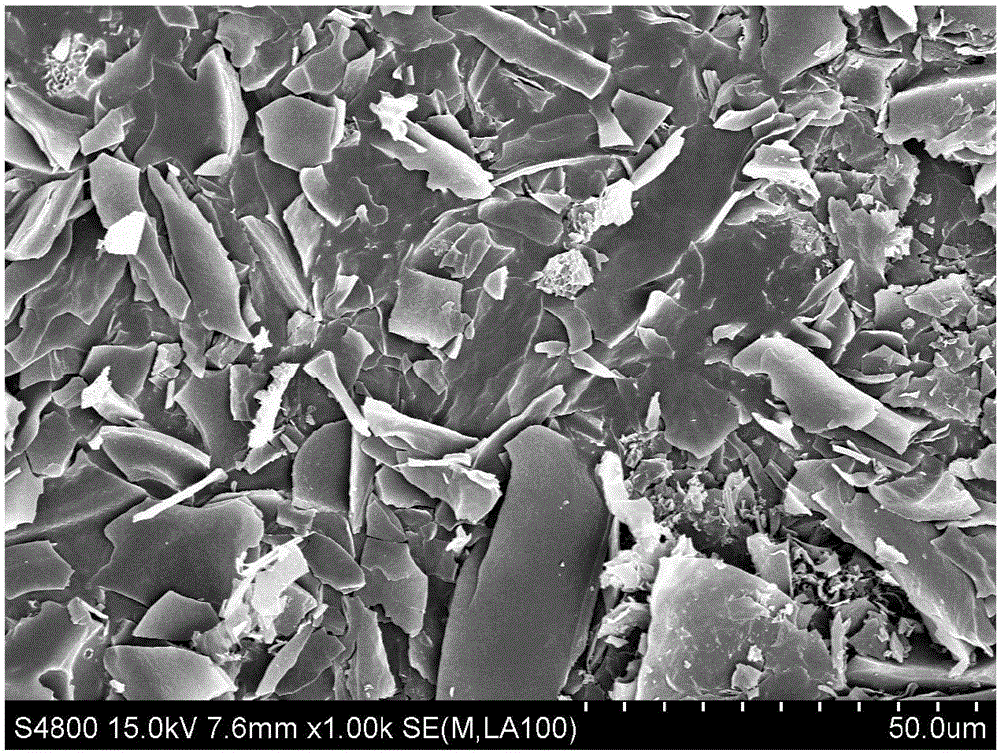

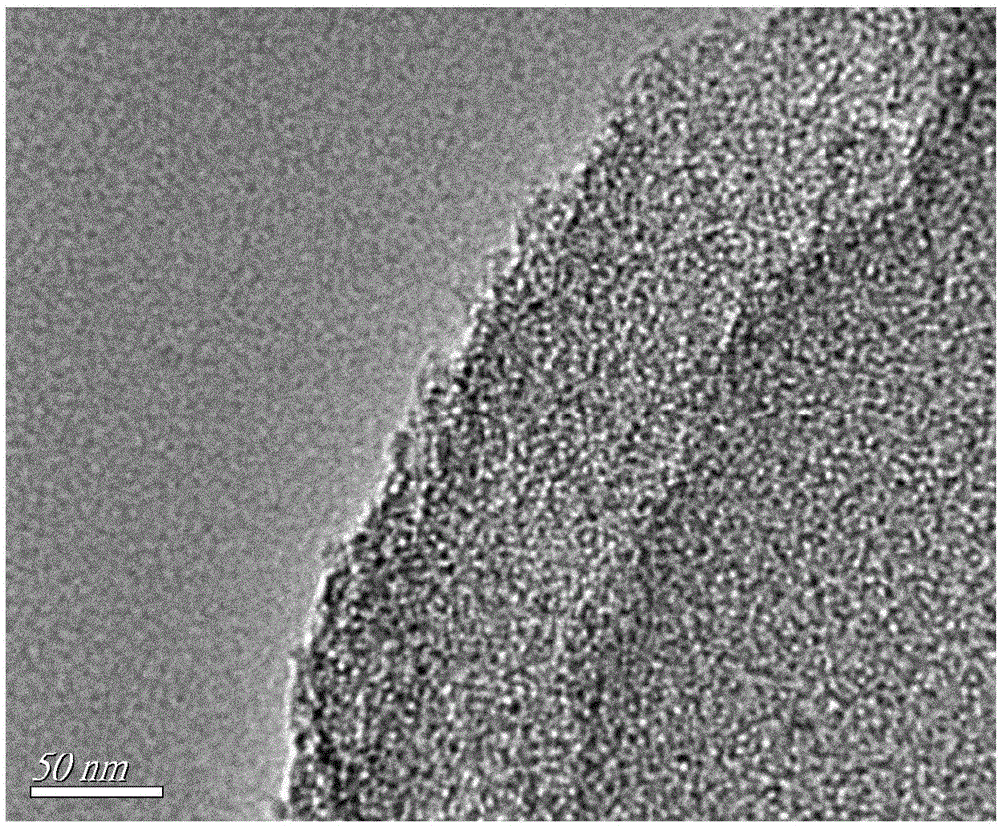

Image

Examples

Embodiment 1

[0032] (1) Synthesis of carbon precursors

[0033] Under the protection of nitrogen, the potassium gluconate was raised to 450 °C at a rate of 5 °C per minute and maintained for 1 h; after the reaction, it was cooled to room temperature, the reaction product was cleaned, and the carbon precursor was obtained after drying.

[0034] Further, washing the reaction product refers to washing the reaction product sequentially with dilute hydrochloric acid, ethanol and water, and the concentration of the dilute hydrochloric acid is 2 mol / L. Drying refers to vacuum drying at 50-60°C.

[0035] (2) Preparation of porous carbon nanomaterials

[0036] Add solid potassium hydroxide to the carbon precursor, and grind to obtain a uniform mixture; under the protection of nitrogen, the above mixture is raised to 850°C at a rate of 5°C per minute and maintained for 1h; after the reaction, cool to room temperature and wash the reaction product , and obtained porous carbon nanomaterials (PCNM) a...

Embodiment 2

[0040] (1) Synthesis of carbon precursors

[0041] Under the protection of nitrogen, the potassium gluconate was raised to 500°C at a rate of 10°C per minute and maintained for 1h; after the reaction, it was cooled to room temperature, the reaction product was cleaned, and the carbon precursor was obtained after drying.

[0042] Further, cleaning the reaction product refers to washing the reaction product sequentially with dilute hydrochloric acid, ethanol and water, the concentration of dilute hydrochloric acid is 2mol / L, and drying refers to vacuum drying at 50-60°C.

[0043] (2) Preparation of porous carbon nanomaterials

[0044] Add solid potassium hydroxide to the carbon precursor, and grind to obtain a uniform mixture; under the protection of nitrogen, the above mixture is raised to 800°C at a rate of 10°C per minute and maintained for 1h; after the reaction, cool to room temperature and wash the reaction product , and obtained porous carbon nanomaterials (PCNM) after d...

Embodiment 3

[0048] (1) Synthesis of carbon precursors

[0049] Under the protection of nitrogen, the potassium gluconate was raised to 500 °C at a rate of 5 °C per minute and maintained for 1 h; after the reaction, it was cooled to room temperature, the reaction product was cleaned, and the carbon precursor was obtained after drying.

[0050] Further, cleaning the reaction product refers to washing the reaction product sequentially with dilute hydrochloric acid, ethanol and water, the concentration of dilute hydrochloric acid is 2mol / L, and drying refers to vacuum drying at 50-60°C.

[0051] (2) Preparation of porous carbon nanomaterials

[0052]Add solid potassium hydroxide to the carbon precursor, and grind to obtain a uniform mixture; under the protection of nitrogen, the above mixture is raised to 850°C at a rate of 5°C per minute and maintained for 1h; after the reaction, cool to room temperature and wash the reaction product , and obtained porous carbon nanomaterials (PCNM) after d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com