Preparation method of graphene

A graphene and fluorinated graphite technology, applied in the field of carbon materials, can solve the problems of inability to restore the two-dimensional crystal structure of graphene, affect the electrical conductivity of graphene, destroy the crystal structure of graphene, etc., achieve excellent electrical properties, restore two-dimensional crystal structure, etc. Crystal structure, the effect of ensuring high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a kind of preparation method of graphene, concrete steps are as follows:

[0030] Under heating conditions, the graphite fluoride and hydrazine hydrate are subjected to a reduction reaction in a liquid phase reaction system to obtain graphene.

[0031] In the present invention, the source of the fluorinated graphite is not particularly limited, and fluorinated graphite well known to those skilled in the art can be used, for example, a commercially available product of fluorinated graphite. In the present invention, the molar ratio of fluorine atoms to carbon atoms in the fluorinated graphite is preferably 1:(0-1.25), and the content of carbon atoms in the fluorinated graphite is not zero, more preferably 1:(0.25 ~1.25), most preferably 1:(0.5~1.25).

[0032] In the present invention, the graphite fluoride and hydrazine hydrate undergo a reduction reaction in a liquid phase system to obtain graphene. In the present invention, the liquid phase sys...

Embodiment 1

[0047] Add 0.5 g of graphite fluoride to 500 mL of hydrazine hydrate solution with a concentration of 50 wt%, and after ultrasonic treatment for 30 min, transfer the mixed solution to a 500 mL round bottom flask, control the reaction temperature at 80°C, and stir magnetically for 6 hours.

[0048] Purification of Graphene

[0049] After the reaction was over, it was naturally cooled to room temperature. The reaction product was transferred to a beaker and filtered. The product is washed out with deionized water, and then centrifuged and washed five times with deionized water, 95% ethanol and acetone at a centrifugal speed of 6000r / min-10000r / min to obtain the graphene product.

[0050] drying of graphene

[0051] The graphene product obtained is vacuum-dried in a vacuum oven for 12h. The vacuum degree of the vacuum drying oven is 0.7MPa, and the temperature is 70°C.

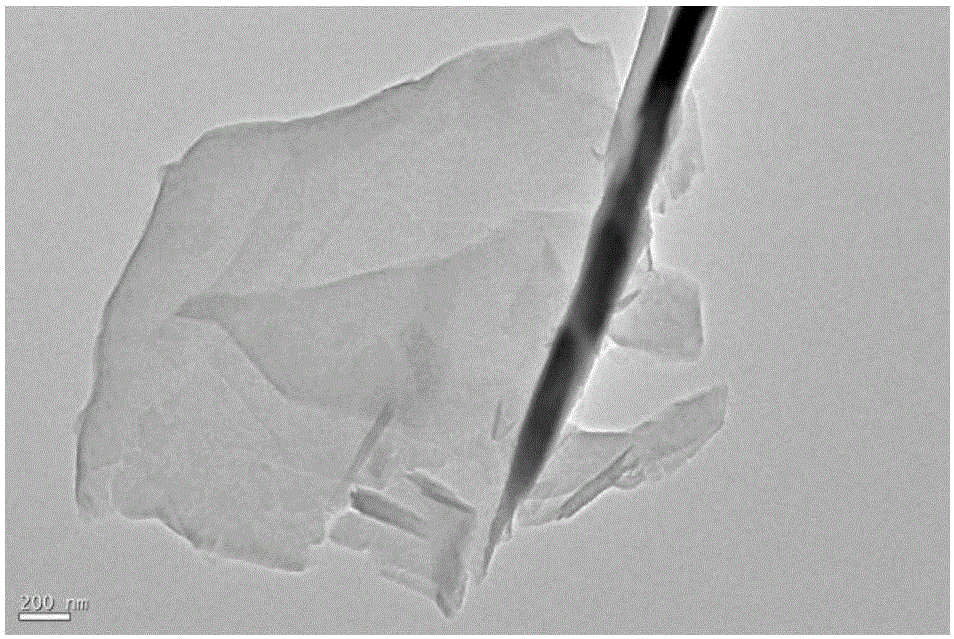

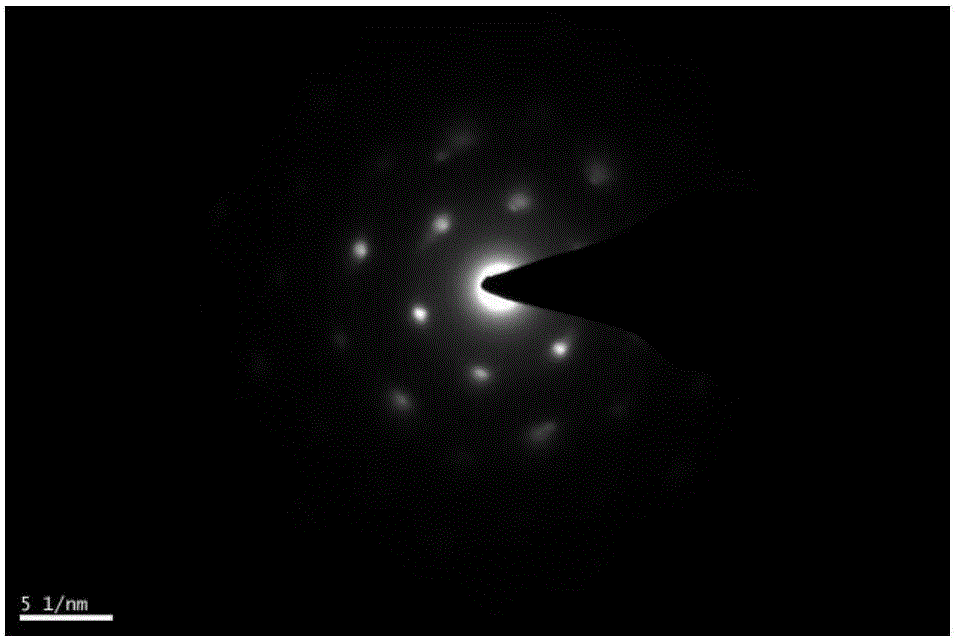

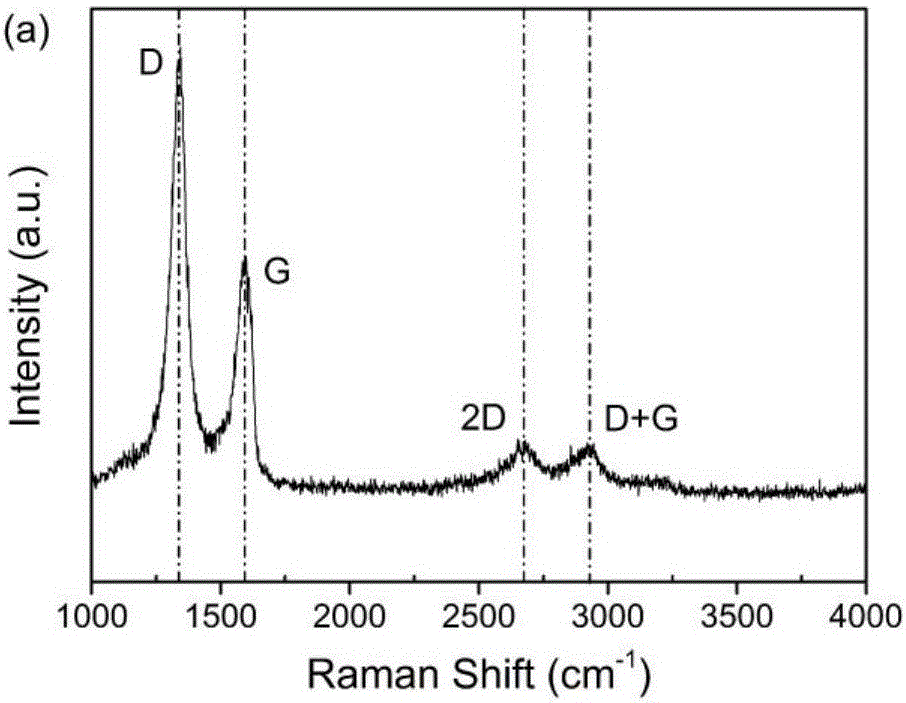

[0052] The present invention carries out morphology and structural characterization of the obtained graphe...

Embodiment 2

[0068] Add 0.1 g of graphite fluoride to 100 mL of hydrazine hydrate solution with a concentration of 35 wt %, and after ultrasonic treatment for 30 min, transfer the mixture to a 500 mL three-neck flask, control the reaction temperature at 80°C, and mechanically stir for 2 hours.

[0069] The purification process is as in Example 1.

[0070] drying of graphene

[0071] The obtained graphene product was freeze-dried in a liquid nitrogen freeze dryer for 24 hours. The temperature of the freeze dryer is minus 48°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com