Machine vision based technical inspection and detection system and method for railway trains

A technology of machine vision and technical inspection, applied in the direction of railway vehicle testing, railway vehicle shape measuring devices, railway car body parts, etc., can solve problems such as violation of operation process, hidden dangers of vehicle operation accidents, hidden dangers of secondary failures, etc., and achieve high assurance Quality, meet the actual application needs, improve the effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

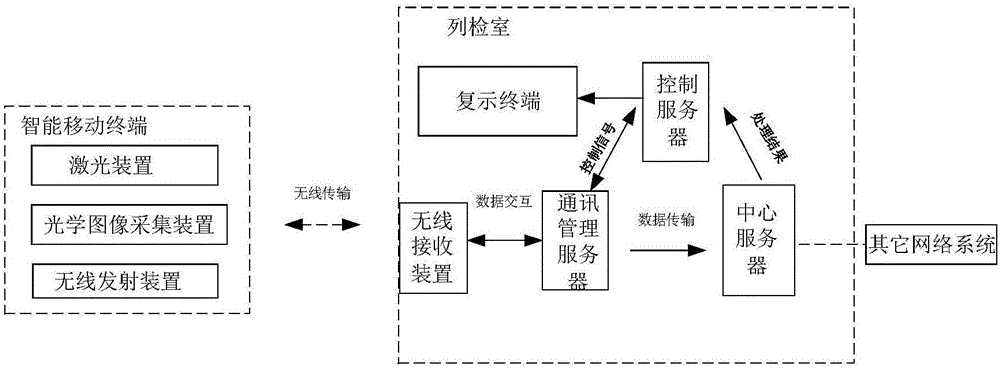

[0034] The invention provides a machine vision-based railway train technology inspection and detection system, the system is as follows figure 1 As shown, it includes outdoor equipment and indoor equipment. The outdoor equipment includes light rails, portable mobile devices, laser devices, optical image acquisition devices and wireless transmitting devices; the indoor equipment includes wireless receiving devices, communication management servers, control server and central server. The indoor equipment and outdoor equipment are relative to the train inspection room.

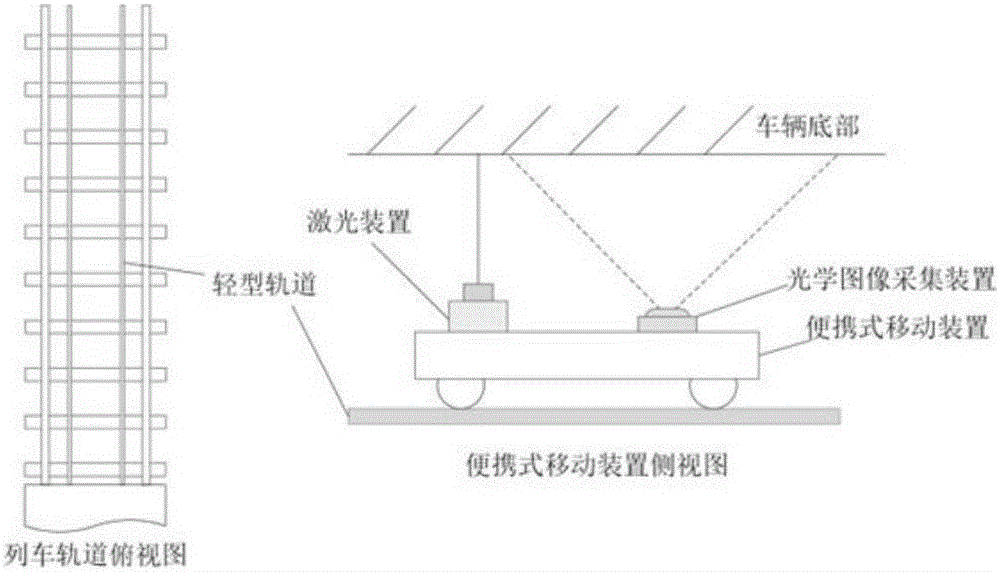

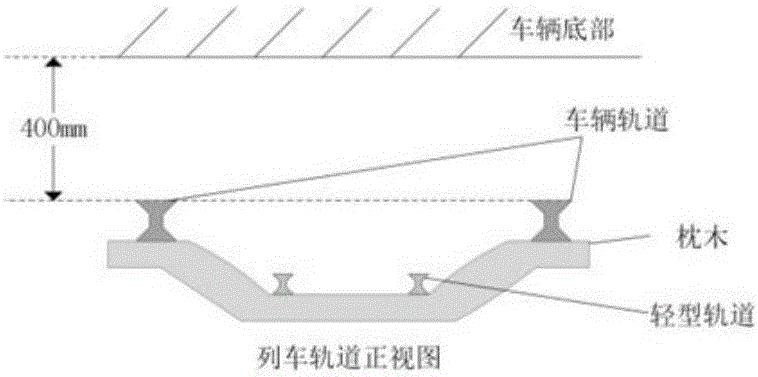

[0035] Such as Figure 2A and Figure 2B As shown, the light track is 2 small steel rails placed on the railway sleepers, the size of the small steel rails matches the size of the portable mobile device, and its main function is to carry the movement of the portable mobile device alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com