An automatic feeding device for a foaming machine

The technology of an automatic feeding device and a foaming machine is applied in the field of lost foam casting, which can solve the problems affecting the efficiency of molding, the quality of the die, the high labor intensity, and the unstable density of the foamed beads, so as to achieve simple installation and reduce labor. Stable and consistent effect of strength and density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

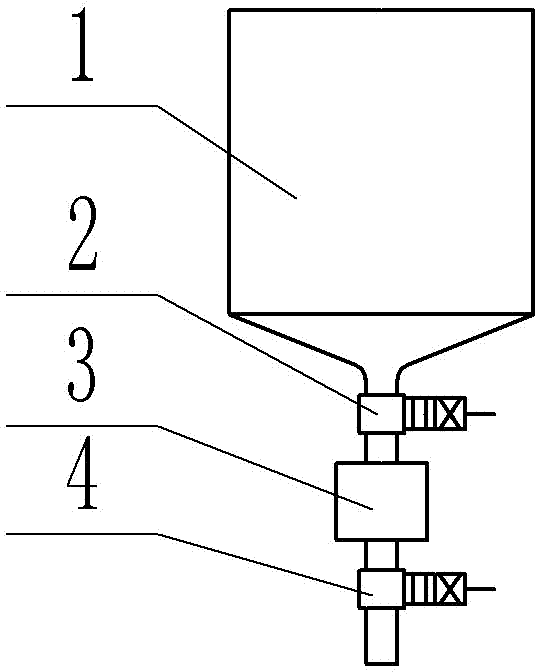

[0018] see figure 1 , an automatic feeding device for a foaming machine, including a barrel 1, an air-controlled butterfly valve A 2, a quantitative device 3, and an air-controlled butterfly valve B 4, the barrel 1 is cylindrical in the upper half and the lower half A funnel-shaped combination, the funnel-shaped outlet below it is connected to the upper inlet flange of the A air-controlled butterfly valve 2, the lower outlet of the A air-controlled butterfly valve 2 is connected to the upper inlet of the quantitative device 3, and the lower outlet of the quantitative device 3 Connect the upper inlet flange of B air-controlled butterfly valve 4, and connect the lower outlet flange of B air-controlled butterfly valve 4 to the feeding mixing tank of the foaming machine.

[0019] The material of the barrel 1 is stainless steel.

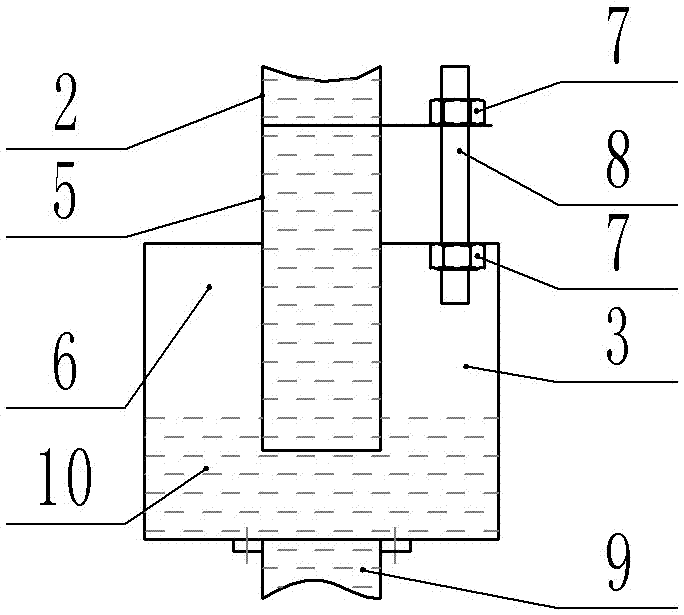

[0020] Described quantifier 3 is made up of small feed bucket 6, straight pipe 5 with internal thread, nut 7, scale 8 with thread, pipe joint 9, and des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com