One-time molding hydraulic press for mine tray

A technology of hydraulic press and tray, which is applied in the field of hydraulic press stamping, can solve the problems of high manufacturing cost and low production efficiency, and achieve the effects of stable product quality, high production efficiency and stable pressing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

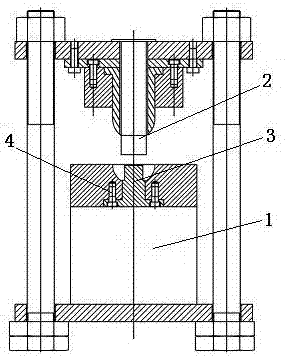

[0011] refer to figure 1 , which includes a hydraulic cylinder 1, an upper die 2, a lower die 3, and a punch 4 is contained in the lower die. The working steps of the present invention are as follows: put the OEM workpiece into the mold cavity, start the oil pressure lifting switch; the oil cylinder drives the upper mold to descend and first press the steel plate into a butterfly-shaped groove; the oil cylinder continues to descend, and the punch in the lower mold implements Punch holes on the butterfly steel plate; finally, the oil cylinder automatically returns to the initial position and waits for the next cycle.

[0012] Before the workpiece is processed, the oil pump must be started first, and the oil cylinder travel switch should be adjusted properly for about 20 minutes without load; during the operation of the equipment, it is strictly forbidden to stop or return at will, otherwise it will cause great damage to the mold.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com