Vehicle suspension spring pressing equipment

A technology of spring pressing and equipment, which is applied in the direction of metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of increasing production costs, operating risks, time-consuming and laborious, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

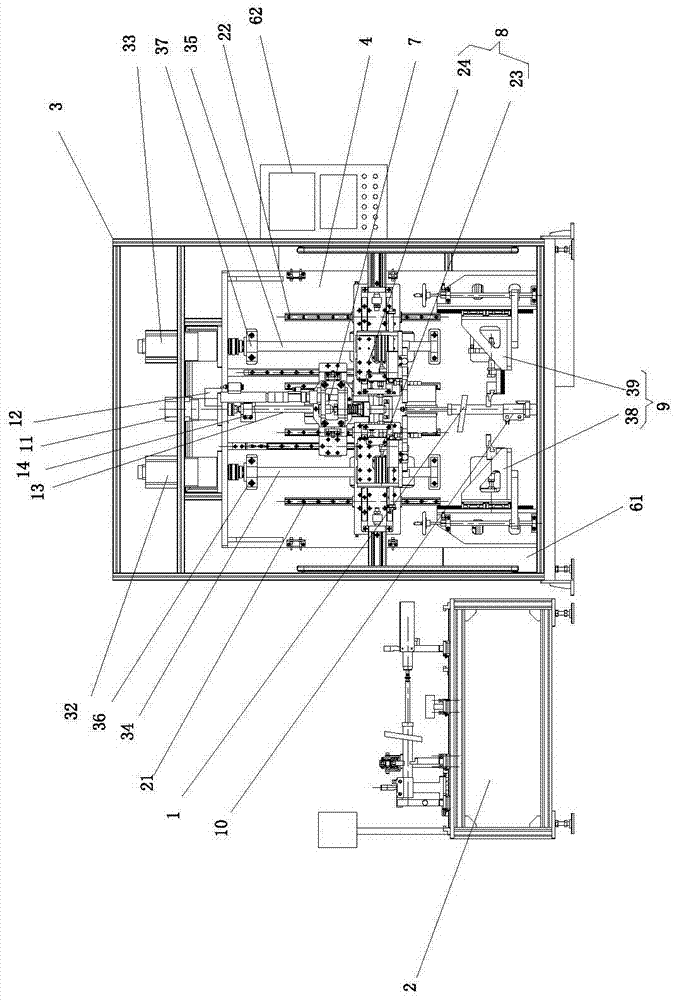

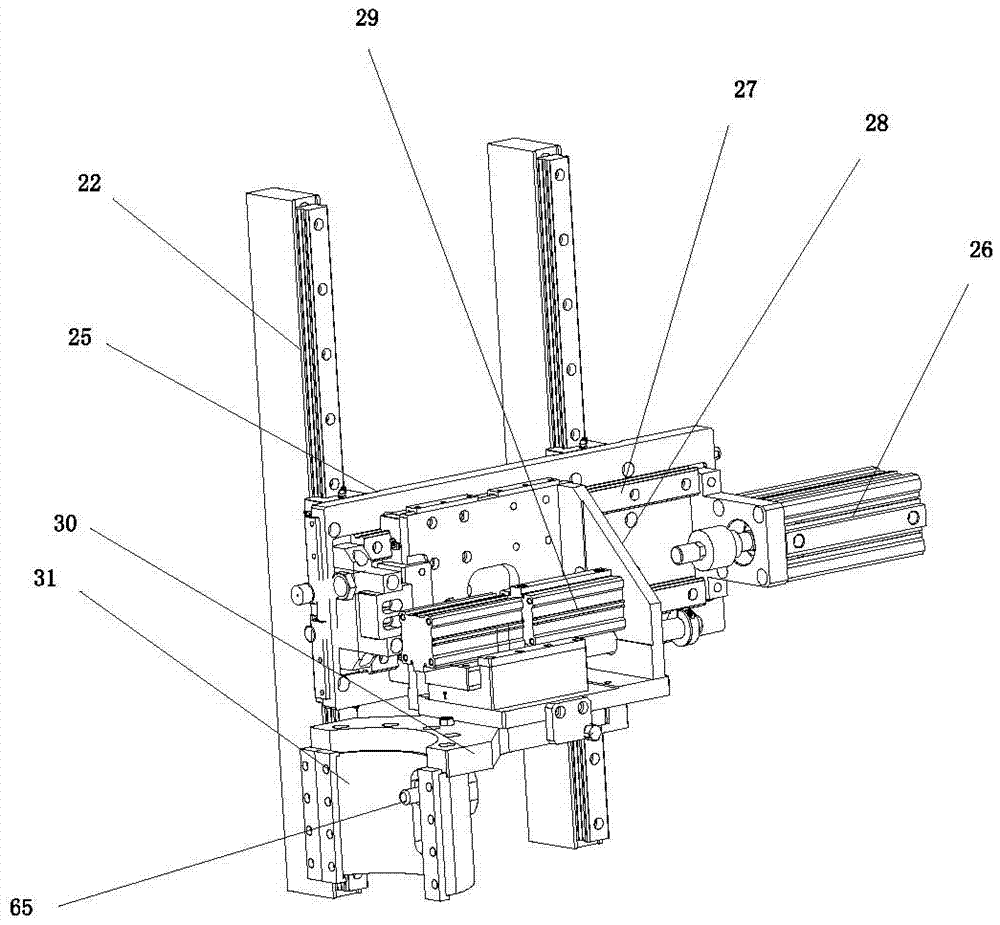

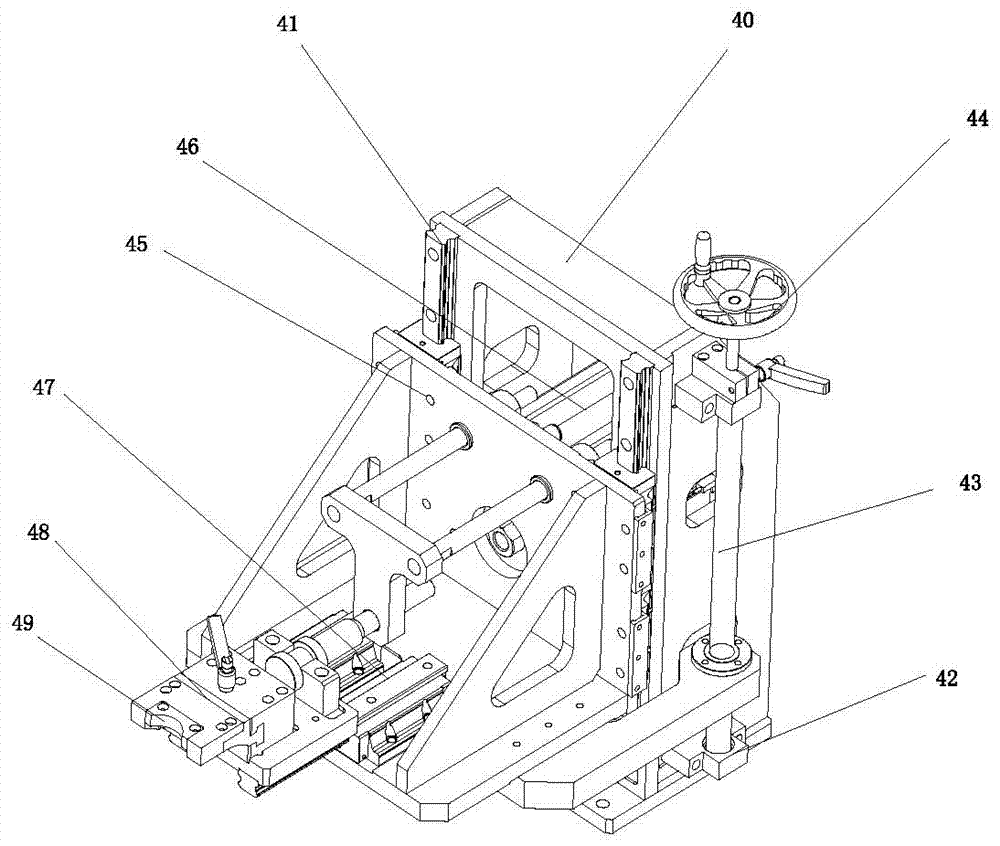

[0017] Depend on Figure 1 to Figure 6 As shown, the present invention includes a press-fitting device and a workpiece detection device 2, the press-fitting device includes a frame body 3, on which a frame plate 4, a tightening shaft motor assembly, a spring-loaded piezoelectric Machine assembly, tightening mechanism 7, spring pressing mechanism 8, clamping mechanism 9 on both sides and workpiece lower positioning seat mechanism 10, described tightening shaft motor assembly includes first rotating motor 11, second rotating motor 12 and first screw mandrel Part 13, on the frame plate 4 is provided with a first fixed seat assembly 14 and a first guide rail assembly 15, the first guide rail assembly 15 is arranged along the longitudinal direction of the frame plate 4, the first screw member 13 is fixed with the first The seat assembly 14 is matched and connected, the driving end of the first rotating motor 11 is connected with the first screw member 13, the first screw member 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com