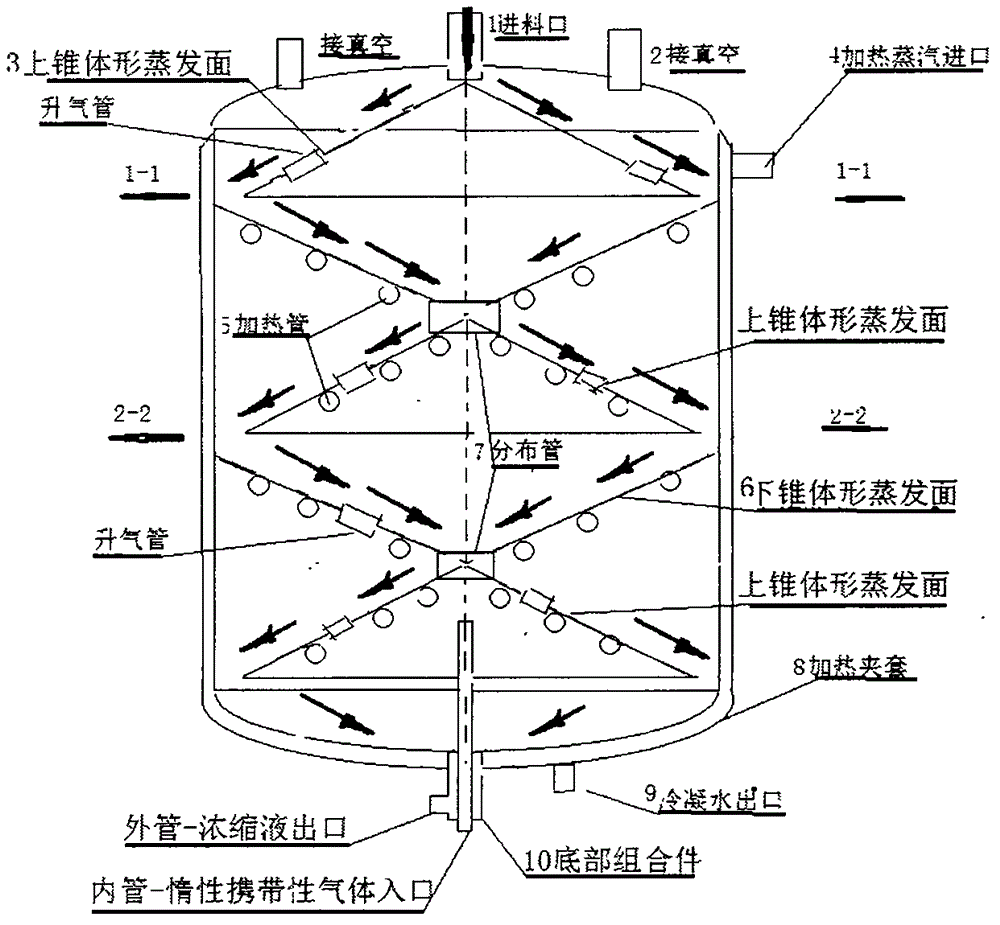

Method for manufacturing thin-layer multi-turn-surface evaporator

A manufacturing method and evaporator technology, applied in chemical instruments and methods, evaporator accessories, evaporation, etc., can solve the problems of long evaporation time, high heat consumption, affecting product quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

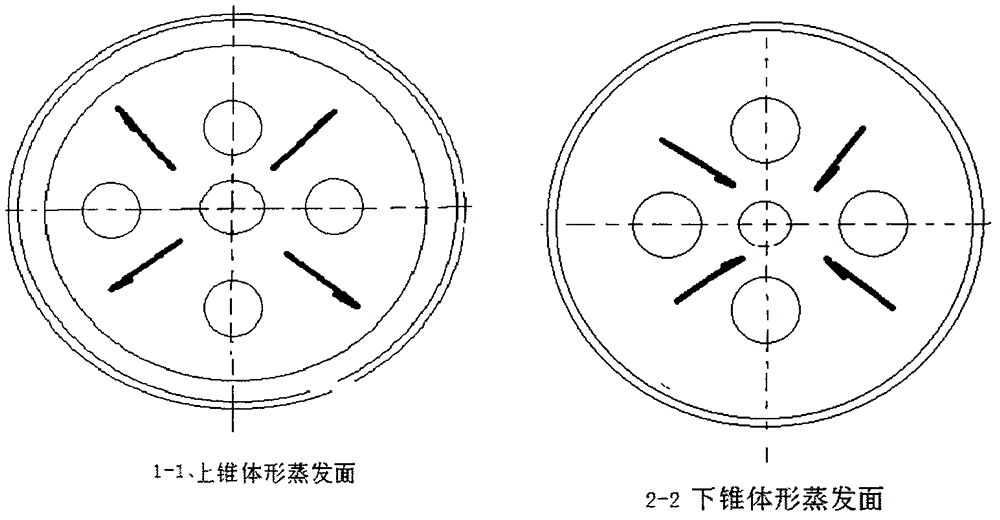

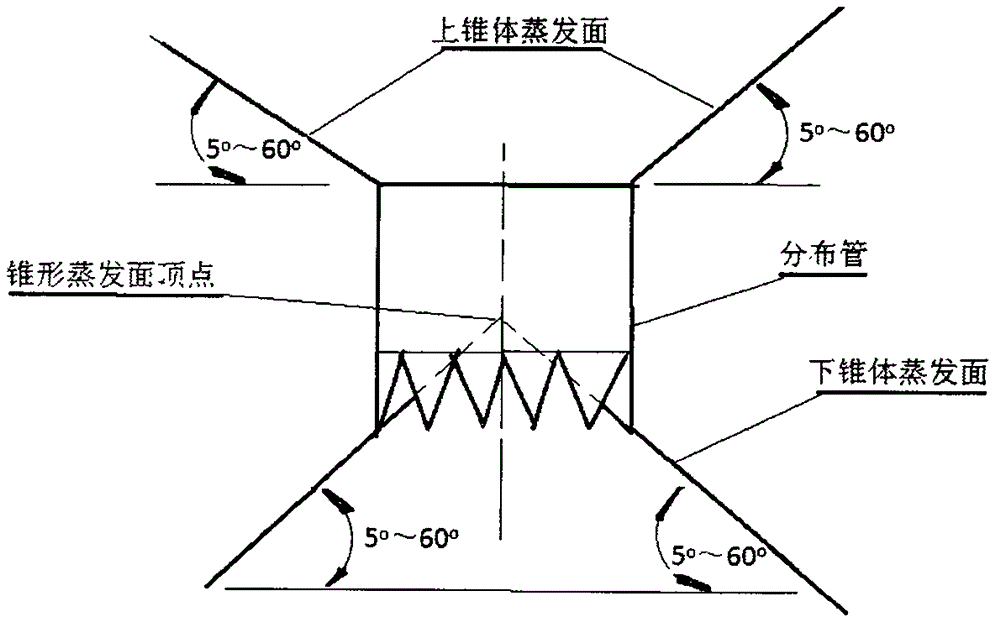

[0020] Conical evaporator made of stainless steel, the angle between the evaporation surface and the horizontal direction is 15°, the distance between the lower end of the cone and the inner wall of the evaporator is 15mm, and 4 fixed holes are set between the lower end of the cone and the inner wall of the evaporator along the perimeter direction. support frame. The conical evaporating surface is provided with 8 air-rising pipes along the perimeter direction, the diameter of the air-rising pipes is φ100mm, and the upper end of the air-rising pipes is 40mm higher than the conical evaporating surface. The evaporation layer of the evaporator is 10 layers. The vacuum evaporation operation method is adopted, the vacuum degree is 80Kpa, the heating temperature is 95° C. with water vapor, and a small amount of nitrogen is added as the carrying gas. From the top of the evaporator, continuously add the liquid with a water content of 4.5% from the solar silicon chip cutting waste liqu...

Embodiment 2

[0022] Conical evaporator made of stainless steel, the angle between the evaporation surface and the horizontal direction is 30°, the distance between the lower end of the cone and the inner wall of the evaporator is 15mm, and 4 fixed holes are set between the lower end of the cone and the inner wall of the evaporator along the perimeter direction. support frame. The conical evaporating surface is provided with 8 air-rising pipes along the perimeter direction, the diameter of the air-rising pipes is φ100mm, and the upper end of the air-rising pipes is 40mm higher than the conical evaporating surface. The evaporation layer of the evaporator is 10 layers. The vacuum evaporation operation method is adopted, the vacuum degree is 80Kpa, the heating temperature is 95° C. with water vapor, and a small amount of nitrogen is added as the carrying gas. From the top of the evaporator, continuously add the liquid with a water content of 4.5% from the solar silicon chip cutting waste liqu...

Embodiment 3

[0024] Conical evaporator made of stainless steel, the angle between the evaporation surface and the horizontal direction is 30°, the distance between the lower end of the cone and the inner wall of the evaporator is 15mm, and 4 fixed holes are set between the lower end of the cone and the inner wall of the evaporator along the perimeter direction. support frame. The conical evaporating surface is provided with 8 air-rising pipes along the perimeter direction, the diameter of the air-rising pipes is φ100mm, and the upper end of the air-rising pipes is 40mm higher than the conical evaporating surface. The evaporation layer of the evaporator is 10 layers. Using the vacuum evaporation operation mode, the vacuum degree is 60Kpa, heated with water vapor, the heating temperature is 95°C, the air in the evaporator is first replaced with nitrogen to an oxygen content of less than 2%, and a small amount of nitrogen is added as a carrying gas. The vitamin C aqueous solution with a wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com