Loading device for densification via chemical infiltration in steam phase in directed flow of three-dimensional porous substrates

A porous substrate and chemical vapor infiltration technology, which is applied in the field of loading equipment for densifying three-dimensional porous substrates through directional flow vapor phase chemical infiltration, can solve the problem of uniform densification of substrates that are difficult to control flow and cannot obtain complex three-dimensional shapes , lack of densification gradient and other issues, to achieve the effect of increasing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

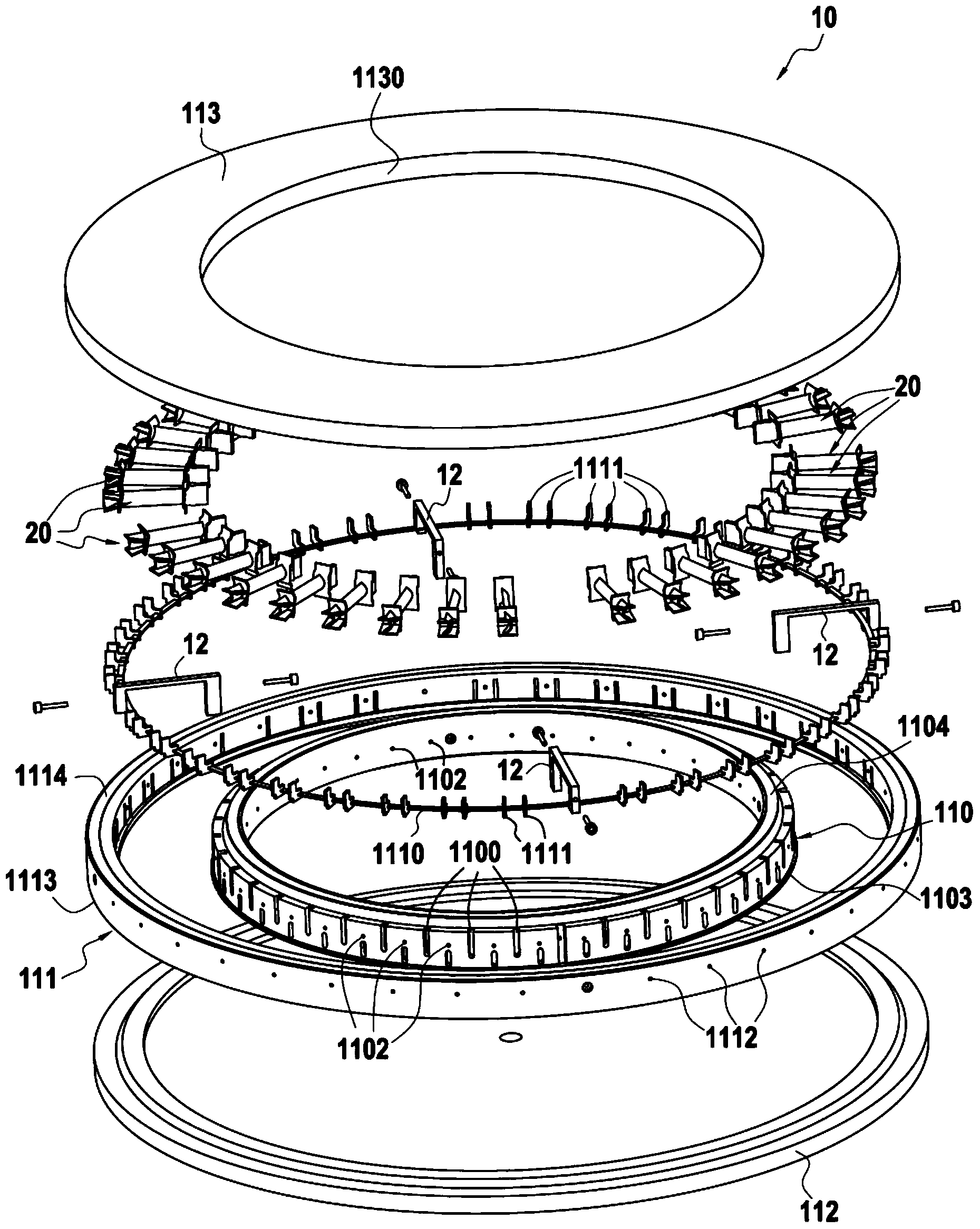

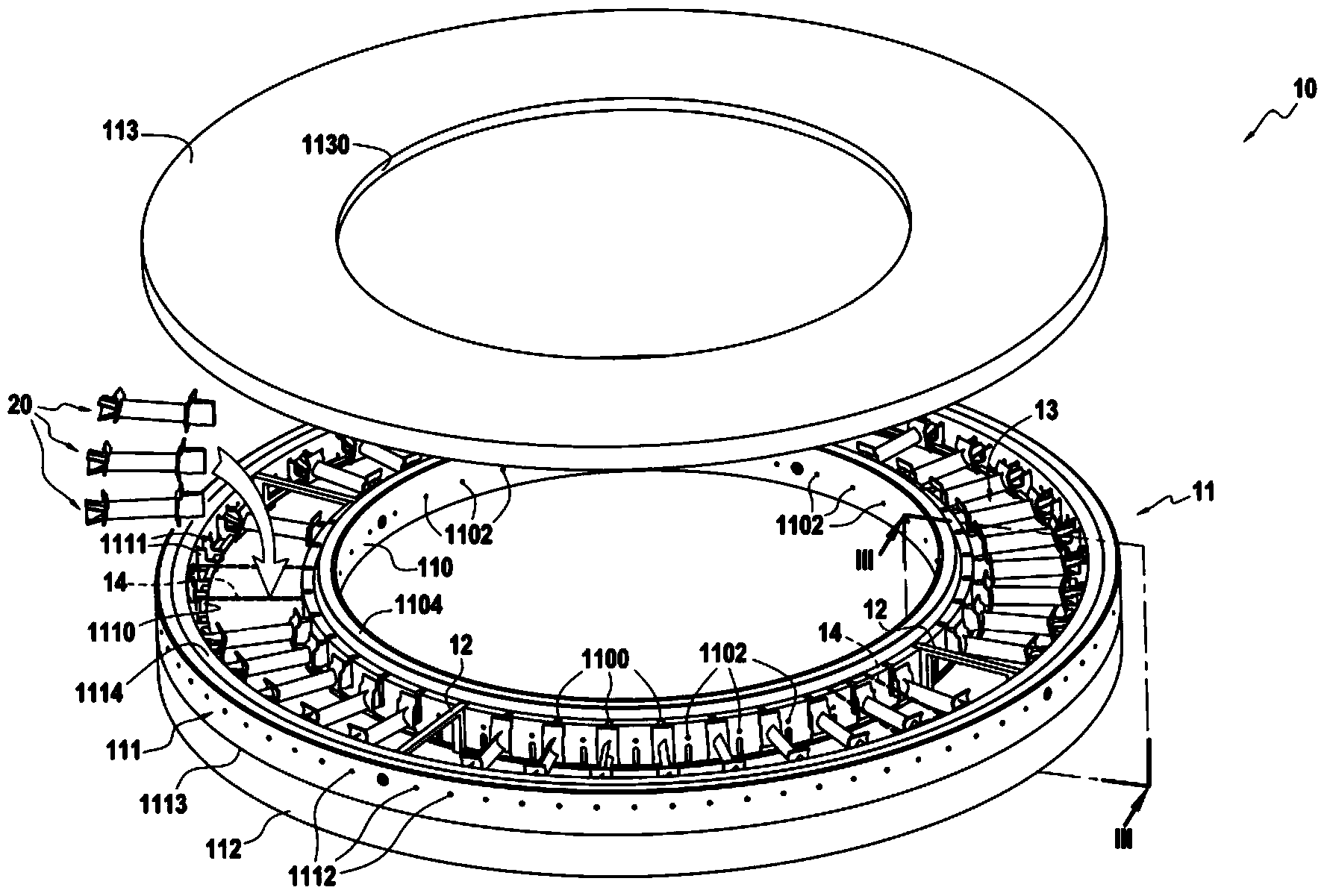

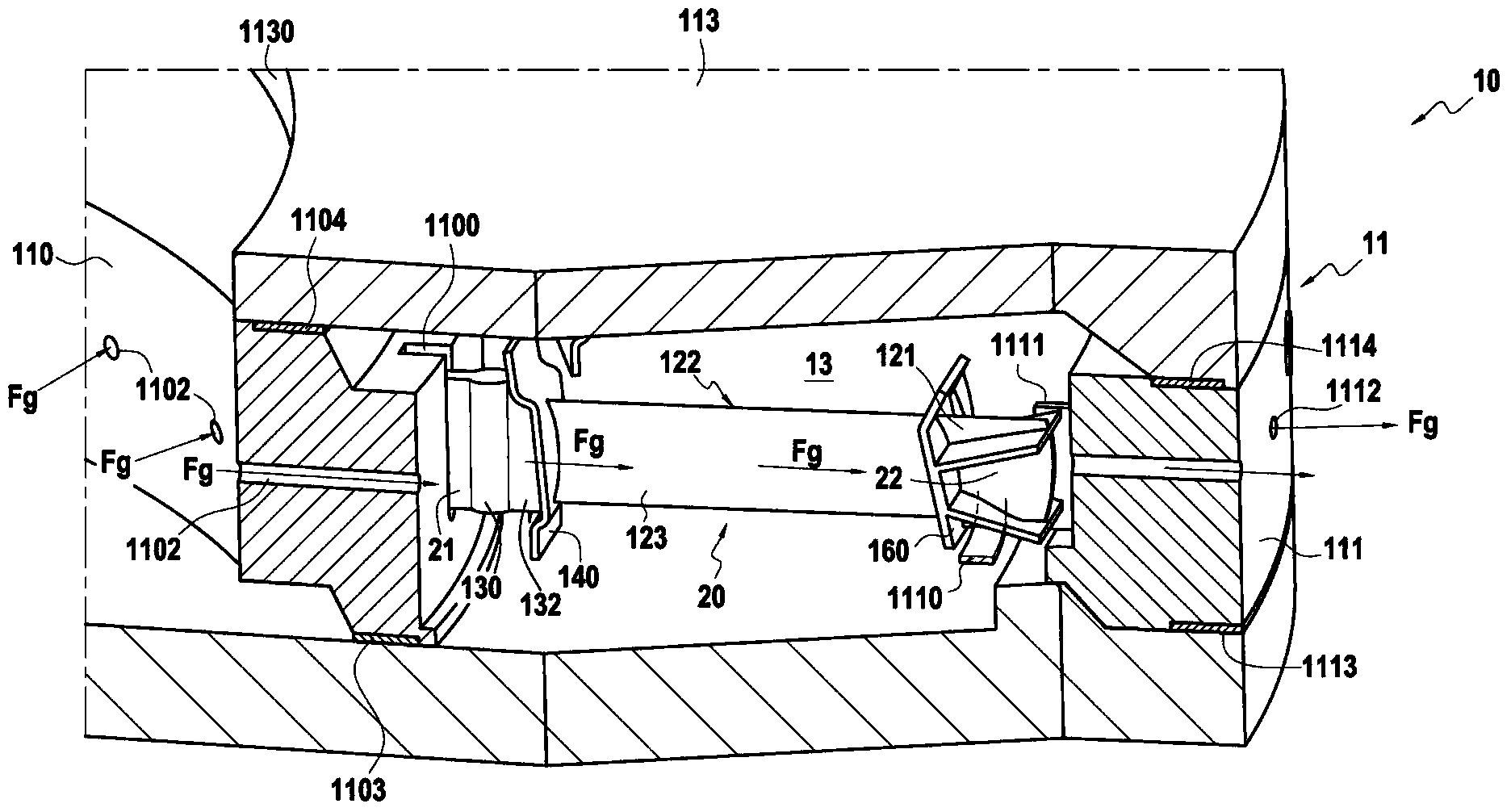

[0040] Figures 1 to 3Shown is a loader device or tool 10 which, once loaded with a substrate for densification, is inserted into a reaction chamber of an industrial plant for chemical vapor infiltration. In the presently described embodiment, the tool 10 is designed to receive a fiber preform 20 for an aeroengine blade.

[0041] Each preform 20 extends in a longitudinal direction between two ends 21 and 22 and comprises a wing 120 and a root 130 formed by a portion of greater thickness, for example with a bulb extending through a tang 132 Section of the shape ( image 3 ). The wing 120 extends in longitudinal direction between its root 130 and its tip 121 and presents in cross-section a curved profile defining a variation in thickness of two surfaces 122 and 123 corresponding respectively to the wing The suction side and the pressure side of the section 120. In the presently described embodiment, the airfoil 120 also has an inner blade platform 140 and an outer blade plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com