Ferritic stainless steel and method for producing same

A manufacturing method, stainless steel technology, applied in the manufacture of tools, furnaces, heat treatment equipment, etc., can solve the problems of insufficient recrystallization, low annealing temperature, low productivity, etc., and achieve the effect of excellent formability and sufficient corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] Hereinafter, the present invention will be described in detail through examples.

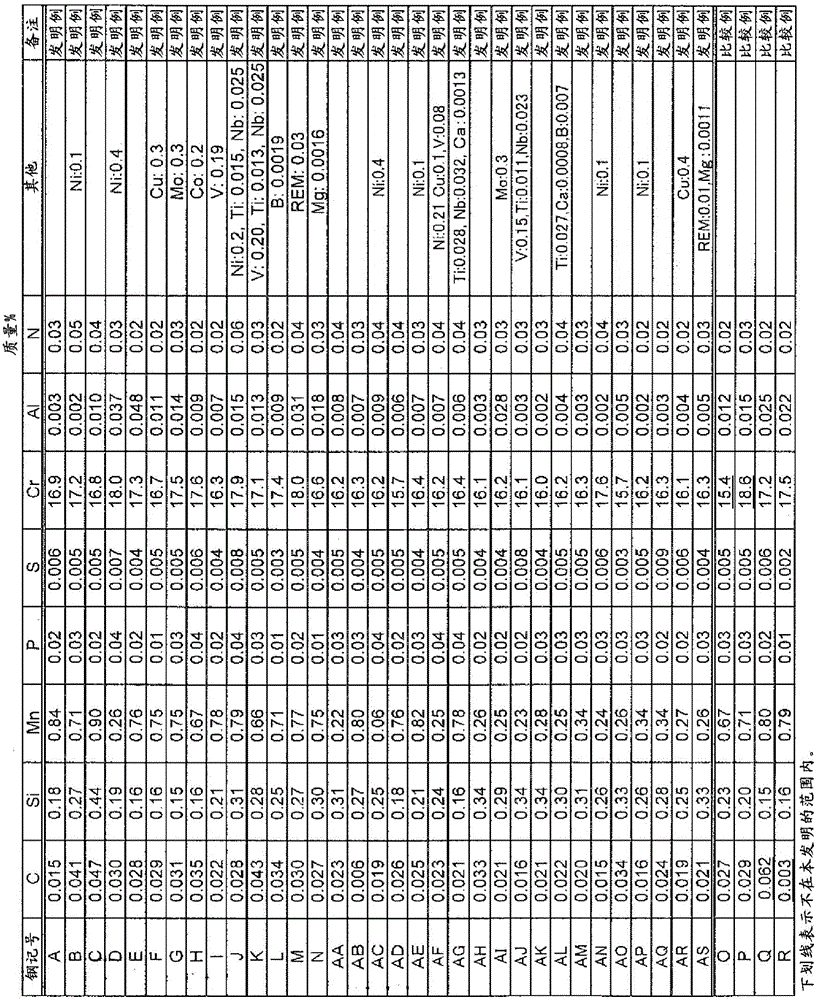

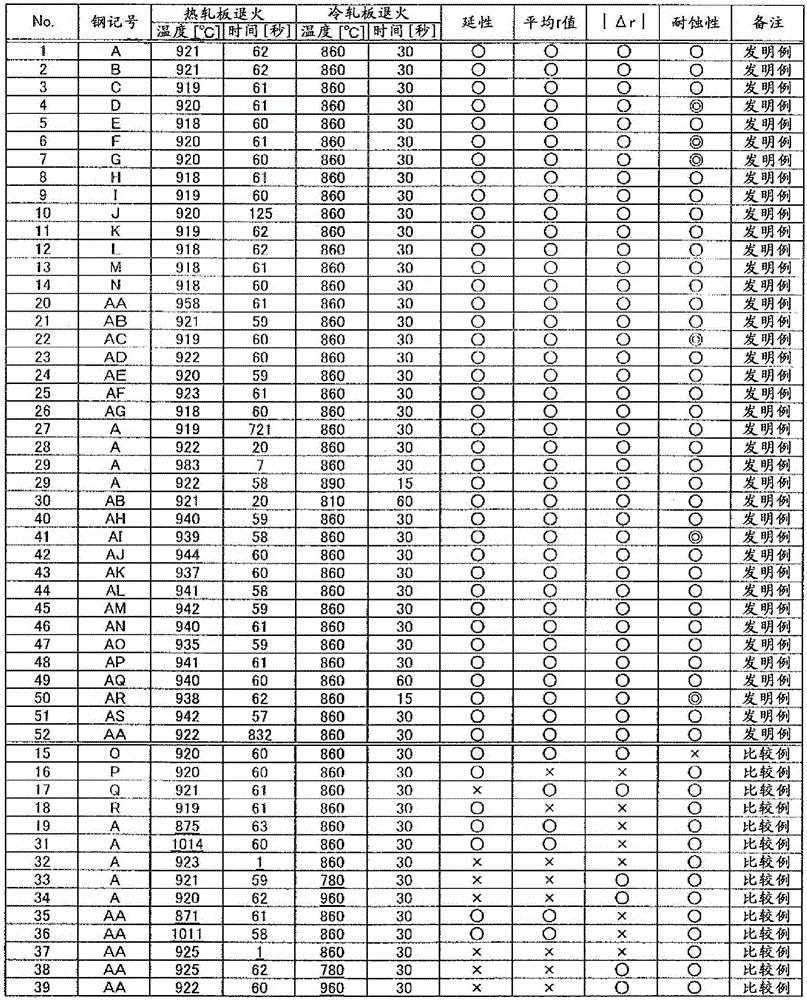

[0084] Stainless steel having the chemical composition shown in Table 1 was cast in a 50 kg small vacuum furnace. These ingots were heated at 1150° C. for 1 hour, and then hot-rolled to obtain 3.5 mm-thick hot-rolled sheets. Next, these hot-rolled sheets were subjected to hot-rolled sheet annealing under the conditions described in Table 2, and then the surfaces were subjected to blasting treatment and descaling by pickling. Further, cold rolling was performed to a thickness of 0.7 mm, followed by annealing of the cold-rolled sheet under the conditions described in Table 2, and then descaling treatment by pickling to obtain a cold-rolled pickled and annealed sheet.

[0085] The following evaluations were performed about the cold-rolled pickling-annealed sheet obtained in this way.

[0086] (1) Evaluation of ductility

[0087] Collect JIS 13B tensile test pieces from the cold-rolled pic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com