High-pressure wall bushing of three-element structure

A technology of high-voltage wall-piercing bushings and wall-piercing bushings, which is applied in the direction of electrical components and insulators, which can solve the problems of high manual consumption of materials, difficulty in ensuring quality, and difficulties in insulators, and achieve the purpose of suppressing pollution flashover and improving corona generation. The effect of increasing the initial voltage and increasing the creepage distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

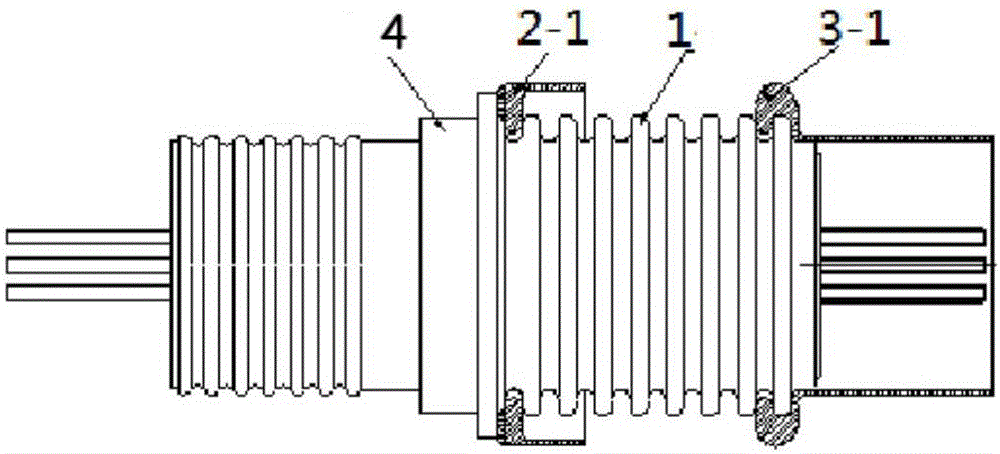

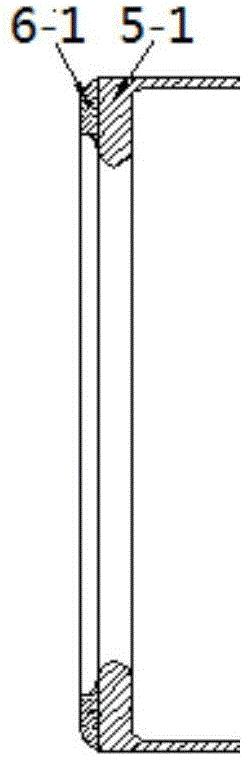

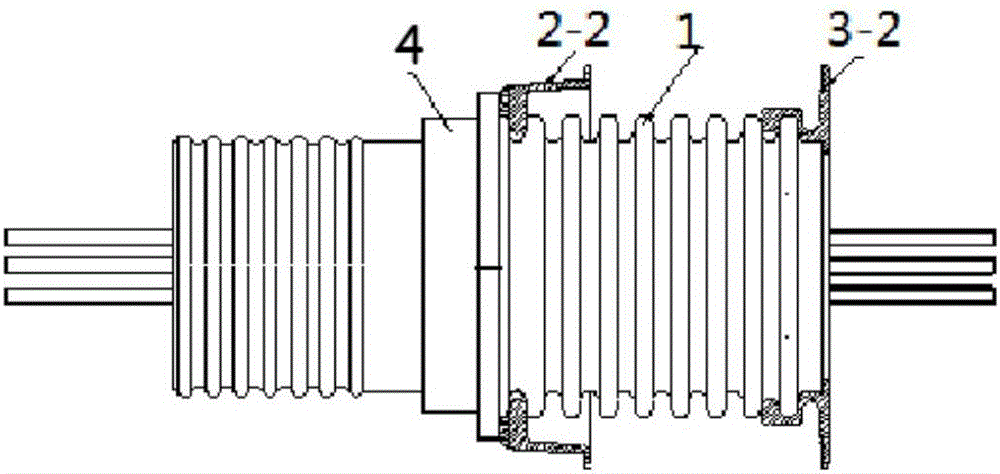

[0027] In the present invention, a grounding side accessory system is arranged on the grounding side of the wall-through bushing, and an electrode side accessory system is arranged on the electrode side.

[0028] The attachment system on the ground side is composed of a ground insulating part and a ground conductive part, and the ground insulating part is in close contact with the ground conductive part; the electrode side attachment system is made of insulating materials.

[0029] The ground conductive portion of the ground side attachment system is in contact with the ground side, and the ground insulating portion is in contact with the ground conductive portion.

[0030] The insulating material of the electrode side attachment system is in contact with the electrode side.

[0031] The insulating material of the insulating part of the grounding side and the electrode side accessory system is a hydrophobic insulating polymer material, and the grounding conductive material of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com