CIGS/CGS double-junction laminated thin film solar cell

A thin-film solar cell and thin-film technology, which is applied in the direction of circuits, photovoltaic power generation, electrical components, etc., can solve the problems of requiring three or four contacts, increasing the cost of battery production, and being unable to directly connect internally, so as to reduce production costs and improve Photoelectric conversion efficiency, the effect of solving the anti-junction phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to further disclose the invention content, features and effects of the present invention, the following examples are specifically cited and described in detail in conjunction with the accompanying drawings as follows.

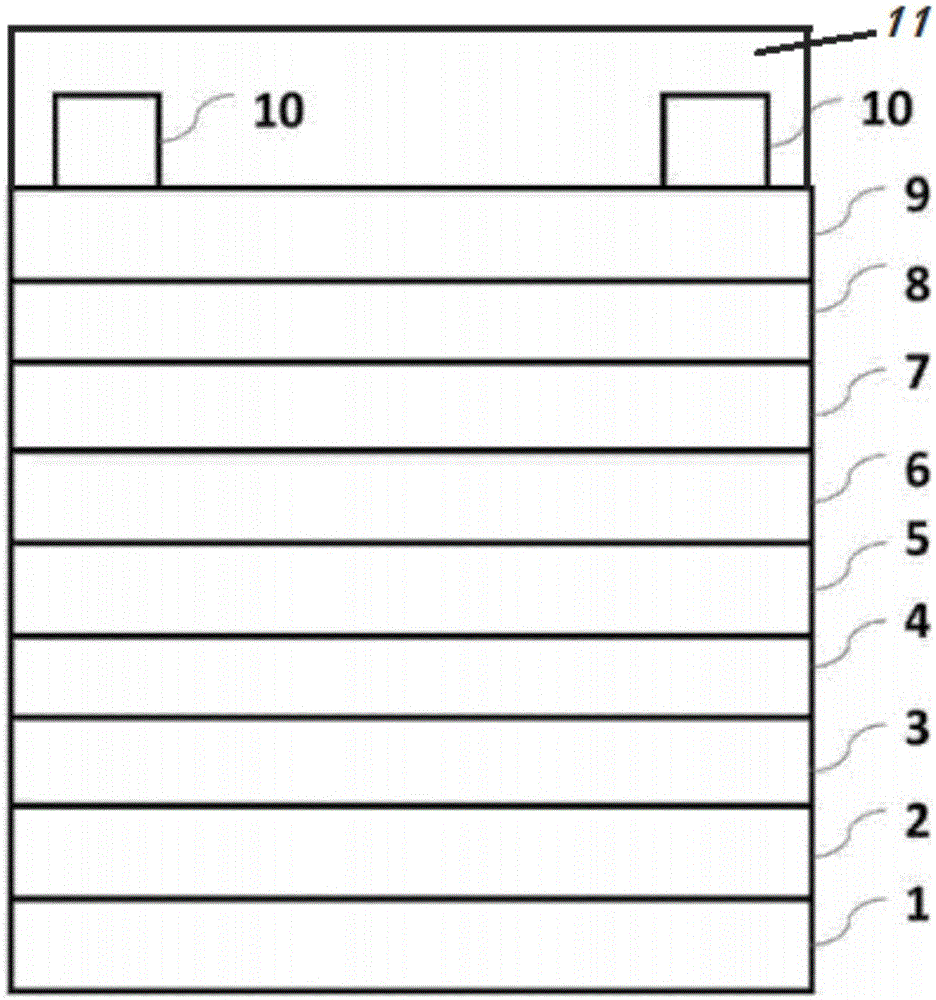

[0019] A CIGS / CGS double-junction stacked thin-film solar cell includes a narrow bandgap copper indium gallium selenide bottom cell and a wide band gap copper gallium selenide top cell.

[0020] Innovation point of the present invention is:

[0021] The bottom cell and the top cell are integrated in series by the connection layer 5; the connection layer is composed of a transparent metal oxide conductive layer positioned at the bottom cell and a nano-metal conductive layer positioned at the top cell, and the copper gallium selenide top cell The conductive window layer 9 includes an ITO composite conductive thin film layer and an ITO thin film layer, and the surface of the conductive window layer and the electrode layer of the copper gallium sele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Conductive | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com